Surface embossing

Use an embossing mold to deform the stainless steel to process the surfaceartistically.

Frosting

Grind the stainless steel surface using materials such as abrasive belts.

Color plating

Plate using electricity, chemical liquid or vacuum to produce stainless steel plates of differentcolors.

Glazing

Glaze the stainless steel products to form a protective membrane to prevent color fading.

-- Primary shaping process

Press the raw material by pressure to make itrequired-thick.

-- Primary shaping process

Be a soft stainless steel plate after hot melting & annealing.

-- Primary shaping process

Set right the stainless steel coils that go through cold rolling and annealing.

-- Cutting

Trim and slit to make the product that meetsthe requirements, especially the ex-factoryrequirements.

-- Cutting

Cut into different-sized stainless steel plates.

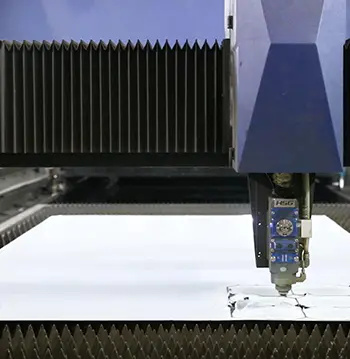

-- Cutting

Irradiate the surface of the stainless steel platewith laser beams to have quick local impact andto achieve a cutting effect.

-- Molding

Splice different parts together to have thedesired shape.

-- Molding

Plane on the stainless steel plates for easyfolding.

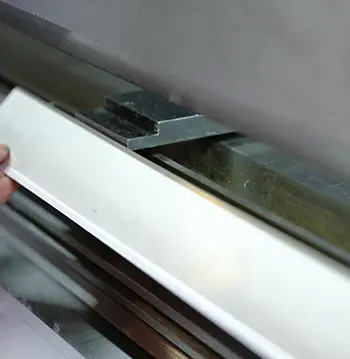

-- Molding

Bend the stainless steel platesby applyingpressure through the upper and lower mold bases.