430 stainless steel coil is a widely used material in various industries due to its exceptional qualities, including its durability, corrosion resistance, and aesthetic appeal. At XINGUANGYUAN, we take pride in producing high-quality 430 stainless steel coil that meet the specific needs and requirements of our clients.

Applications of 430 stainless steel coil

430 stainless steel coil finds application in a wide range of industries, including construction, automotive, aerospace, food processing, and medical equipment. The versatile material is used for various purposes, such as manufacturing kitchen appliances, heat exchangers, chemical processing equipment, and architectural components.

Pros of 430 stainless steel coil

430 stainless steel coil offers several advantages, making it an excellent choice for many applications. Some of its pros include:

-

Corrosion resistance: 430 stainless steel coilcontains chromium, which makes it highly resistant to corrosion and staining.

-

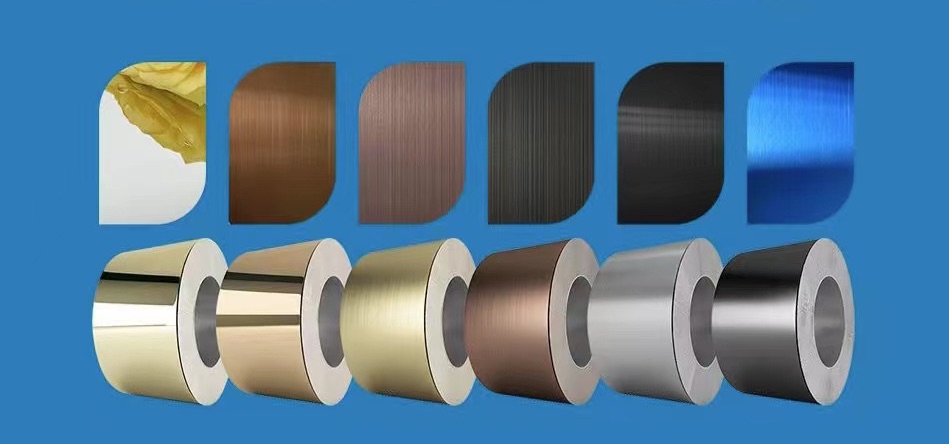

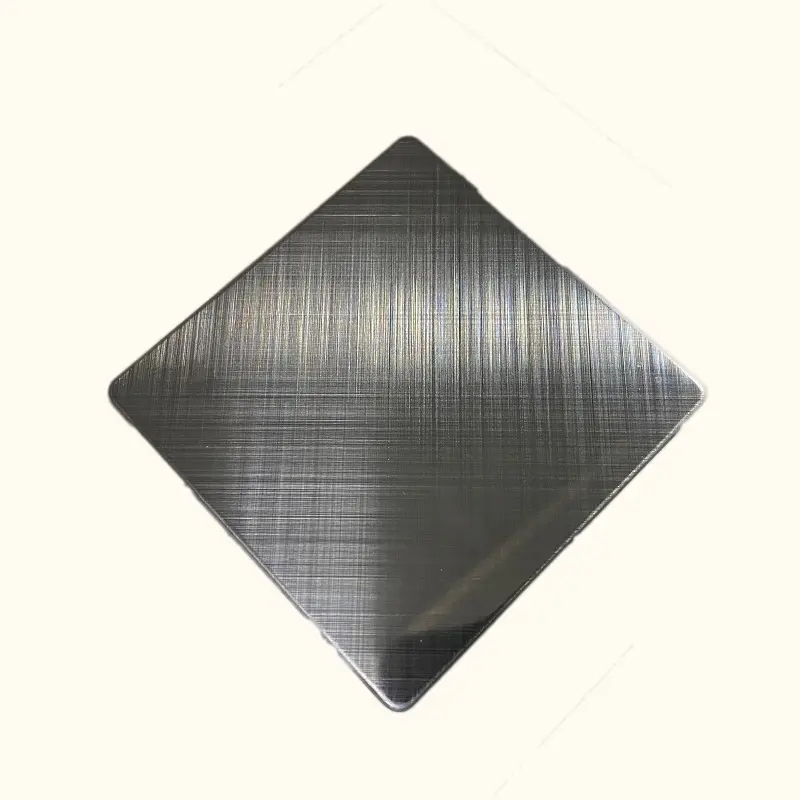

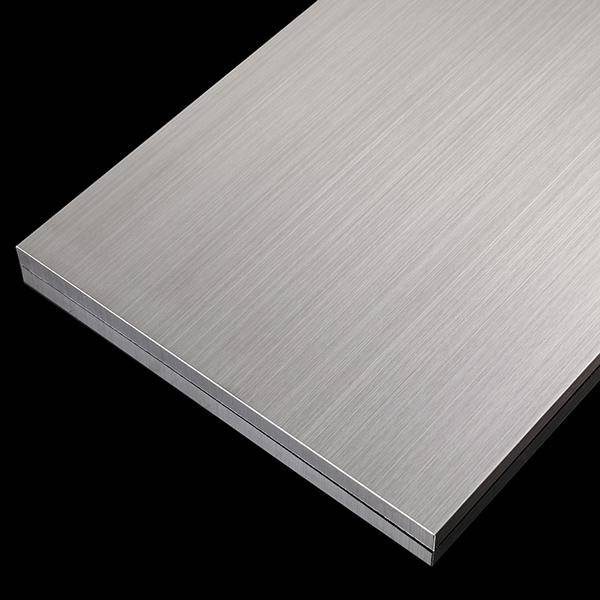

Aesthetic appeal: The polished surface of 430 stainless steel coil gives it a sleek and modern look, making it an attractive choice for decorative applications.

-

Durability: 430 stainless steel coil is a durable material that can withstand harsh conditions and extreme temperatures.

-

Low maintenance: 430 stainless steel coil requires minimal maintenance, making it a cost-effective option in the long run.

Popular FAQs about 430 stainless steel coil

- What is the difference between 430 stainless steel coil and sheet?

430 stainless steel coil is a continuous roll of steel that is wound up into a coil, while stainless steel sheet is a flat sheet of steel.

- What is the maximum temperature that 430 stainless steel coilcan withstand?

The maximum temperature that 430 stainless steel coilcan withstand depends on the specific grade of stainless steel. In general, most 430 stainless steel coil can withstand temperatures up to 1500°F (815°C).

- How is 430 stainless steel coil cleaned?

430 stainless steel coil can be cleaned using a mild detergent and water. Harsh chemicals and abrasive cleaners should be avoided, as they can damage the surface of the steel.

430 stainless steel coil is a versatile and durable material that is used in various industries due to its excellent properties. At XINGUANGYUAN, we offer high-quality 430 stainless steel coil that meet the specific needs and requirements of our clients. Whether you need 430 stainless steel coil for architectural components or chemical processing equipment, we have you covered. Contact us today to learn more about our products and services.

.jpg)

.jpg)