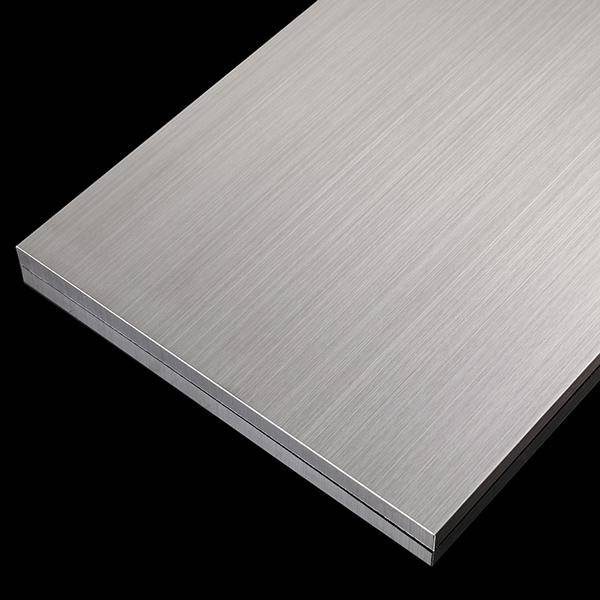

Etching Stainlee steel sheets are versatile materials used in a wide range of industries, from automotive to construction, food processing to medical equipment. As a leading supplier of Etching Stainlee steel sheets , XINGUANGYUAN is committed to providing high-quality products that meet the needs of various applications.

Applications of Etching Stainlee steel sheets

Etching Stainlee steel sheets are commonly used in applications that require high strength, corrosion resistance, and durability. Here are some of the most common applications:

-

Architecture and construction: Etching Stainlee steel sheets are used for roofing, wall cladding, and structural support.

-

Automotive: Etching Stainlee steel sheets are used in the manufacturing of exhaust systems, body panels, and trim components.

-

Food processing: Etching Stainlee steel sheets are used in food processing equipment due to their hygienic properties and resistance to corrosion.

-

Medical equipment: Etching Stainlee steel sheets are used in the manufacturing of surgical instruments, implants, and medical devices due to their biocompatibility and durability.

-

Petrochemical industry: Etching Stainlee steel sheets are used in the manufacturing of pipes, tanks, and valves that are exposed to high temperatures and corrosive environments.

Pros of Etching Stainlee steel sheets

-

Corrosion resistance: Etching Stainlee steel sheets are highly resistant to corrosion, making them ideal for applications in harsh environments.

-

Strength and durability: Etching Stainlee steel sheets are extremely strong and durable, making them ideal for applications that require high strength and longevity.

-

Hygienic properties: Etching Stainlee steel sheets are easy to clean and maintain, making them ideal for use in the food processing and medical industries.

-

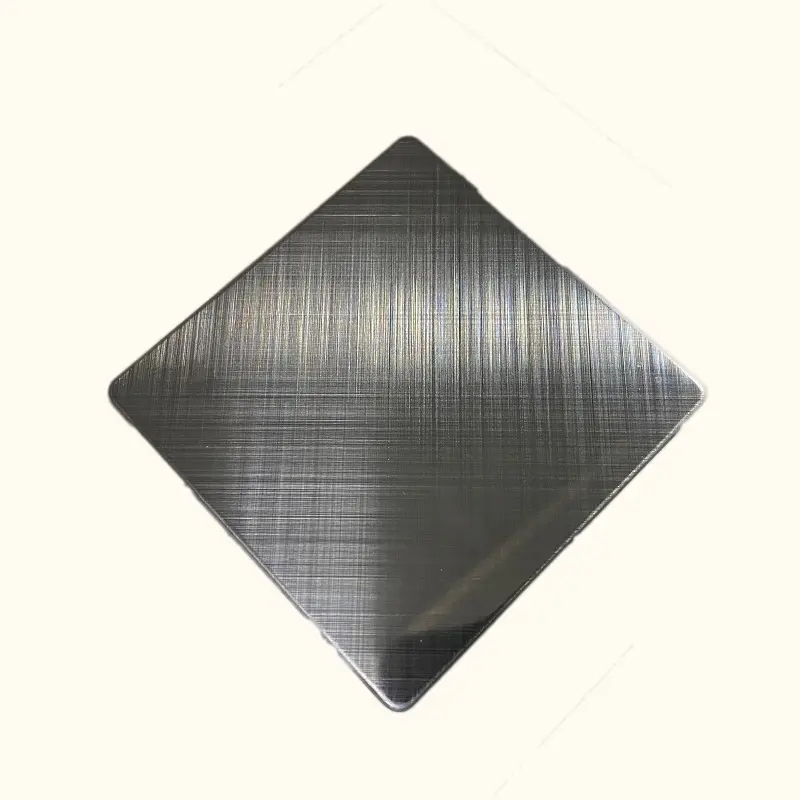

Aesthetic appeal: Etching Stainlee steel sheets have a clean, modern look that makes them popular for architectural and design applications.

Popular FAQs about Etching Stainlee steel sheets

Q: How is Etching Stainlee steel sheets made?

A: Etching Stainlee steel sheets is made by cold-rolling or hot-rolling a flat steel strip, then annealing it to remove any stresses and improve its ductility.

Q: How do I choose the right grade of Etching Stainlee steel sheets for my application?

A: The right grade of Etching Stainlee steel sheets depends on the specific requirements of your application, including the level of corrosion resistance needed, the strength required, and any other factors such as temperature or magnetism.

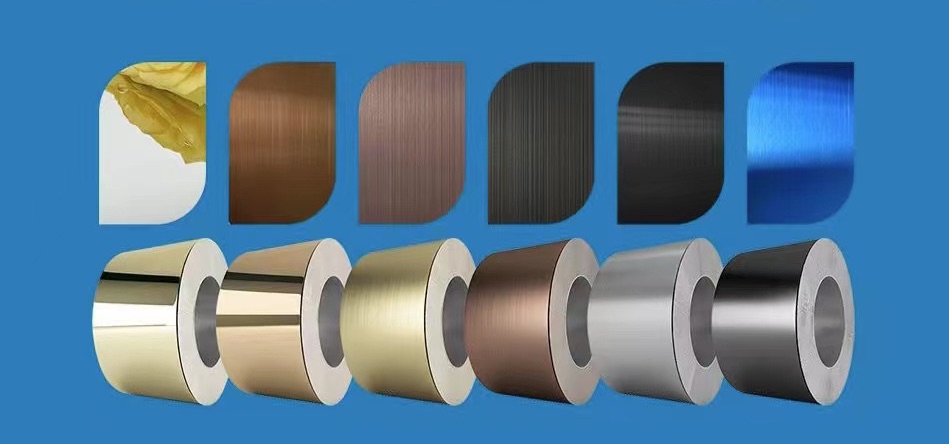

Q: Can Etching Stainlee steel sheets be painted or coated?

A: Yes, Etching Stainlee steel sheets can be painted or coated using a variety of methods, including powder coating, electroplating, or spray painting.

Etching Stainlee steel sheets are an essential material in a wide range of applications due to their strength, durability, and corrosion resistance. At XINGUANGYUAN, we are committed to providing high-quality Etching Stainlee steel sheets that meet the specific needs of our customers. If you have any further questions about Etching Stainlee steel sheets or would like to place an order, please don't hesitate to contact us.

.jpg)

.jpg)