301 1/4 Hard Stainless Steel is a highly versatile and durable austenitic alloy, renowned for its exceptional strength, corrosion resistance, and formability. This material is widely used across industries, from architectural components and automotive parts to kitchen utensils, due to its unique combination of properties that make it a preferred choice for both manufacturers and designers. Whether you're looking for 301 stainless steel 1/4 hard properties or applications, this alloy offers a solution that meets diverse needs.

Understanding 301 1/4 Hard Stainless Steel

The 301 1/4 hard stainless steel is an austenitic grade that has undergone cold rolling to achieve its quarter-hard temper. This process increases the material's strength and hardness, making it suitable for mild drawing, stretching, and forming operations. With a minimum tensile strength of 125,000 PSI (862 MPa) and a minimum yield strength of 75,000 PSI (517 MPa), as specified in ASTM A666, this grade exhibits exceptional mechanical properties that contribute to its durability and resilience.

Composition and Properties

The 301 1/4 hard stainless steel composition includes:

- Chromium: 16-18%

- Nickel: 6-8%

- Carbon: 0.15% maximum

- Manganese: 2% maximum

- Silicon: 1% maximum

- Phosphorus: 0.045% maximum

- Sulfur: 0.03% maximum

This balanced composition provides key properties:

Corrosion Resistance: Chromium forms a protective oxide layer, making it suitable for marine and industrial environments.

Strength and Hardness: Cold-rolling enhances mechanical properties, ideal for applications requiring high strength.

Formability: Retains excellent formability despite increased strength, allowing for bending, drawing, and stamping.

Weldability: Exhibits good weldability for complex assemblies.

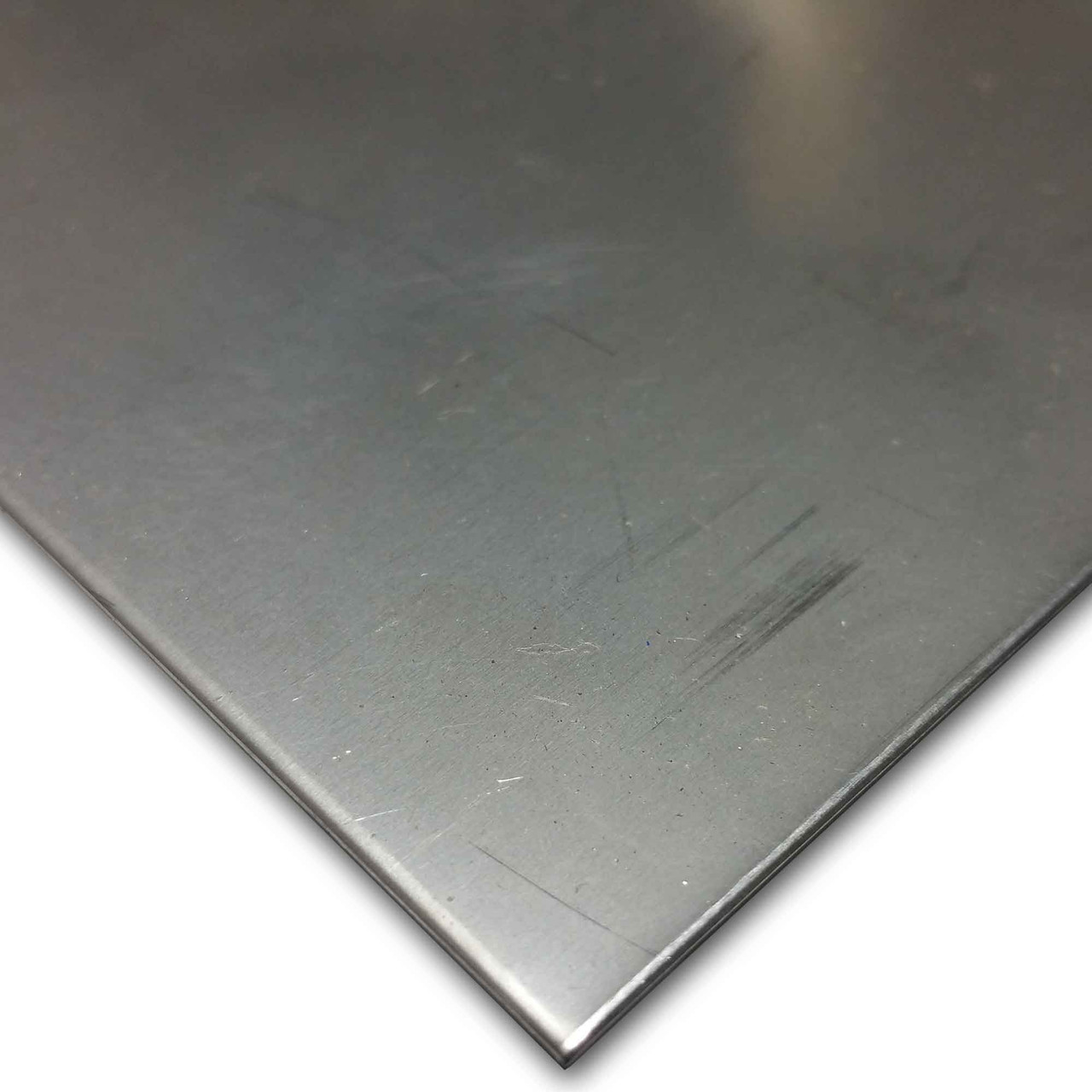

Aesthetic Appeal: Offers a bright, semi-reflective surface suitable for decorative uses.

Manufacturing Process

The production of 301 1/4 hard stainless steel sheets involves a series of carefully controlled processes to ensure consistent quality and performance. The manufacturing steps typically include:

-

Melting and Refining: The raw materials, including chromium, nickel, and other alloying elements, are melted in an electric arc furnace or a basic oxygen furnace. The molten metal is then refined to remove impurities and adjust the chemical composition to meet the required specifications.

-

Casting: The molten metal is cast into semi-finished forms, such as ingots or continuous cast slabs, using various casting techniques.

-

Hot Rolling: The cast forms are heated and then passed through a series of rolling mills to reduce their thickness and shape them into hot-rolled coils or plates.

-

Cold Rolling: The hot-rolled material is further processed through cold rolling mills, which apply significant pressure to reduce the thickness and impart the desired quarter-hard temper to the stainless steel sheets.

-

Annealing and Pickling: After cold rolling, the sheets may undergo annealing (heat treatment) to relieve internal stresses and improve ductility. Pickling, a chemical treatment process, is then performed to remove surface oxides and contaminants, resulting in a clean and bright surface.

-

Surface Finishing: Depending on the desired application, 301 1/4 hard stainless steel sheets can undergo various surface finishing processes, such as polishing, brushing, or etching, to achieve the desired aesthetic or functional properties.

Throughout the manufacturing process, strict quality control measures are implemented to ensure that the final product meets the required specifications and industry standards, such as ASTM A666 and AMS 5517.

Applications of 301 1/4 Hard Stainless Steel Sheets

The unique combination of properties exhibited by 301 1/4 hard stainless steel sheets makes them suitable for a wide range of applications across various industries. Some of the most common applications include:

-

Architectural and Construction: The corrosion resistance, strength, and aesthetic appeal of 301 1/4 hard stainless steel sheets make them an excellent choice for architectural components, such as cladding, roofing, and decorative panels. They are also used in the construction of structural elements, railings, and hardware.

-

Automotive and Transportation: The automotive industry extensively utilizes 301 1/4 hard stainless steel sheets for various components, including trim pieces, wheel covers, exhaust systems, and fuel tanks. The material's formability and corrosion resistance contribute to the longevity and performance of these components.

-

Kitchen Appliances and Utensils: The food-grade properties and ease of cleaning make 301 1/4 hard stainless steel sheets an ideal choice for kitchen appliances, cookware, and utensils. The material's durability and resistance to staining and corrosion ensure a long service life in these applications.

-

Industrial Equipment: The strength and corrosion resistance of 301 1/4 hard stainless steel sheets make them suitable for various industrial applications, such as chemical processing equipment, storage tanks, and pressure vessels.

-

Medical and Pharmaceutical Industries: The non-toxic and hygienic nature of 301 1/4 hard stainless steel sheets, combined with their corrosion resistance and ease of cleaning, make them suitable for medical and pharmaceutical equipment, surgical instruments, and clean room components.

-

Decorative Applications: The attractive appearance and formability of 301 1/4 hard stainless steel sheets allow for their use in decorative applications, such as furniture, lighting fixtures, and artistic installations.

Sustainability and Eco-Friendliness

One of the key advantages of 301 1/4 hard stainless steel sheets is their sustainability and eco-friendliness. Stainless steel is a highly recyclable material, with a recycling rate of over 80% globally. This not only reduces the environmental impact of steel production but also contributes to the conservation of natural resources.

Furthermore, the durability and long service life of 301 1/4 hard stainless steel sheets minimize the need for frequent replacements, further reducing the environmental footprint associated with material production and disposal. Many stainless steel manufacturers, including Xinguangyuan, have implemented sustainable practices and technologies to minimize energy consumption, reduce emissions, and promote responsible resource management throughout the production process.

Surface Finishes and Customization

To cater to the diverse requirements of various applications, 301 1/4 hard stainless steel sheets are available in a range of surface finishes. Some of the most common finishes include:

- Mirror Finish: A highly reflective and smooth surface achieved through extensive polishing, suitable for decorative applications and high-end architectural projects.

- Brushed Finish: A directional, linear pattern created by brushing the surface, providing a uniform and attractive appearance while minimizing the visibility of scratches and fingerprints.

- Bead Blasted Finish: A matte, non-reflective finish achieved by blasting the surface with small glass beads, creating a uniform and consistent texture.

- Etched Finish: A decorative finish created by chemically etching patterns or designs onto the surface of the stainless steel sheet, often used for artistic or architectural applications.

In addition to these standard finishes, Xinguangyuan offers customized surface treatments and finishes to meet the specific requirements of their clients. This includes specialized coatings, textures, and patterns tailored to the desired aesthetic or functional needs.

Quality Control and Industry Standards

Ensuring consistent quality and adherence to industry standards is of utmost importance in the production of 301 1/4 hard stainless steel sheets. Xinguangyuan implements rigorous quality control measures throughout the manufacturing process, including:

- Raw Material Inspection: Incoming raw materials are thoroughly inspected to ensure they meet the required chemical composition and quality standards.

- In-Process Testing: Various tests and inspections are conducted at different stages of the manufacturing process to monitor and control critical parameters, such as dimensional accuracy, surface quality, and mechanical properties.

- Final Inspection: Finished 301 1/4 hard stainless steel sheets undergo a comprehensive final inspection to verify compliance with customer specifications and industry standards.

- Certification: Xinguangyuan provides material test reports (MTRs) and certifications to ensure traceability and compliance with relevant industry standards, such as ASTM A666, AMS 5517, and ISO 9001.

By adhering to these stringent quality control measures and industry standards, Xinguangyuan ensures that their 301 1/4 hard stainless steel sheets meet the highest quality and performance requirements, providing customers with reliable and consistent products.

Xinguangyuan's Expertise and Customized Solutions

At Xinguangyuan, we take pride in our extensive experience and expertise in stainless steel surface processing techniques, enabling us to offer superior stainless steel products and customized solutions tailored to the unique needs of our clients. Our team of skilled professionals works closely with customers to understand their specific requirements and provide tailored solutions that optimize the performance and aesthetics of their products.

One notable example of Xinguangyuan's expertise is our collaboration with a leading automotive manufacturer to develop a customized 301 1/4 hard stainless steel sheet for their high-performance exhaust systems. By working closely with the client's engineering team, we were able to create a solution that not only met their stringent performance requirements but also significantly improved the durability and corrosion resistance of the exhaust components, resulting in reduced maintenance costs and extended service life.

Conclusion

In conclusion, 301 1/4 hard stainless steel is a versatile material that offers a unique blend of strength, corrosion resistance, formability, and aesthetic appeal. Its wide range of applications makes it an indispensable choice across various industries. For those seeking 301 stainless steel 1/4 hard properties or looking to integrate this material into their projects, understanding its composition and manufacturing process can help optimize its use. Contact us today to explore how our 301 1/4 hard stainless steel sheets can enhance your designs and products.

At Xinguangyuan, we are committed to providing our customers with the highest quality 301 1/4 hard stainless steel sheets, backed by our extensive expertise, customized solutions, and dedication to sustainability. Whether you are an architect, designer, or manufacturer, partnering with Xinguangyuan ensures access to superior stainless steel products that can elevate your projects to new heights.

Contact us today to explore the possibilities and discover how our 301 1/4 hard stainless steel sheets can enhance your designs and products, while benefiting from our commitment to quality, innovation, and environmental responsibility.