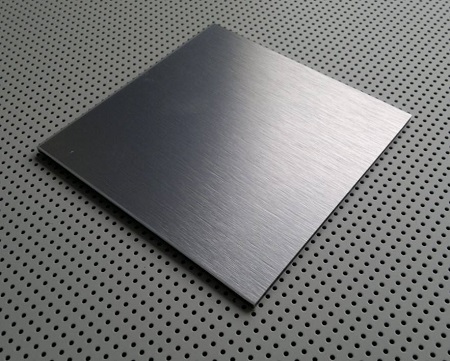

The 304 stainless steel sheet with a #4 brushed finish combines exceptional durability, corrosion resistance, and aesthetic appeal, making it a premier choice for architects, designers, and manufacturers across industries. This versatile material showcases a perfect balance of form and function, offering unparalleled brilliance in both appearance and performance. Let's explore the unique characteristics, applications, and benefits of this remarkable stainless steel finish.

Understanding 304 Stainless Steel

304 stainless steel is an austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and formability. Composed of approximately 18% chromium and 8% nickel, this grade of stainless steel offers:

- Superior resistance to a wide range of corrosive environments

- Excellent formability and weldability

- High strength-to-weight ratio

- Non-magnetic properties (in annealed condition)

- Exceptional durability and longevity

These properties make 304 stainless steel one of the most widely used grades globally, finding applications in various industries from food processing to architecture.

The #4 Brushed Finish: A Closer Look

The #4 brushed finish is a popular surface treatment applied to stainless steel sheets, creating a distinctive linear grain pattern. This finish is achieved through a mechanical process called brushing, where fine-grit abrasives are used to create a uniform, directional texture on the metal surface.

Key advantages of the #4 brushed finish include:

-

Enhanced Aesthetics: The linear grain pattern adds a subtle yet visually appealing texture, perfect for modern architectural and interior design applications.

-

Improved Durability: The brushing process increases surface hardness, making the material more resistant to scratches and wear.

-

Easy Maintenance: The directional grain helps camouflage minor scratches and blemishes, reducing the need for frequent polishing.

-

Light Diffusion: The brushed surface effectively diffuses light, minimizing glare and creating a softer, more elegant appearance.

Applications Across Industries

The versatility of 304 stainless steel sheet with a #4 brushed finish makes it an ideal choice for numerous applications:

Architectural and Interior Design

- Wall cladding and paneling

- Elevator interiors

- Decorative columns and beams

- Handrails and balustrades

- Signage and wayfinding elements

Food and Beverage Industry

- Commercial kitchen equipment

- Food processing machinery

- Refrigeration units

- Serving counters and display cases

Healthcare and Medical Facilities

- Surgical tables and equipment

- Laboratory workstations

- Hospital room fixtures

- Pharmaceutical processing equipment

Transportation and Automotive

- Vehicle trim and accents

- Public transportation interiors

- Aircraft galley components

- Marine fittings and hardware

Manufacturing Process and Quality Control

The production of 304 stainless steel sheets with a #4 brushed finish involves several critical steps:

-

Melting and Casting: Raw materials are melted in an electric arc furnace and cast into semi-finished forms.

-

Hot and Cold Rolling: The material undergoes rolling processes to achieve desired thickness and improve mechanical properties.

-

Annealing and Descaling: Heat treatment relieves internal stresses, followed by descaling to remove surface oxides.

-

Brushing: Specialized equipment applies the #4 finish, creating the signature linear grain pattern.

-

Quality Control: Rigorous testing ensures adherence to international standards and specifications.

Sustainability and Eco-Friendliness

304 stainless steel with a #4 brushed finish is an environmentally responsible choice:

- Highly recyclable (over 80% recycling rate in many regions)

- Long service life reduces the need for frequent replacements

- Corrosion resistance minimizes maintenance and resource consumption

Maintenance and Care

To preserve the brilliance of 304 stainless steel with a #4 brushed finish:

- Clean regularly with mild detergents and soft cloths

- Avoid abrasive cleaners or harsh chemicals

- For stubborn stains, use a stainless steel-specific cleaner

- In high-traffic areas, consider protective coatings to maintain appearance

Conclusion: Brilliance Unveiled

304 stainless steel sheet with a #4 brushed finish truly unveils brilliance in both form and function. Its combination of corrosion resistance, durability, and aesthetic appeal makes it an invaluable material for a wide range of applications. From sleek architectural elements to hygienic food processing equipment, this versatile finish continues to set the standard for excellence in the stainless steel industry.

By choosing 304 stainless steel with a #4 brushed finish, designers, manufacturers, and end-users alike can enjoy the perfect balance of performance, longevity, and visual appeal. As industries continue to evolve, this remarkable material stands ready to meet the challenges of tomorrow with unmatched brilliance and versatility.