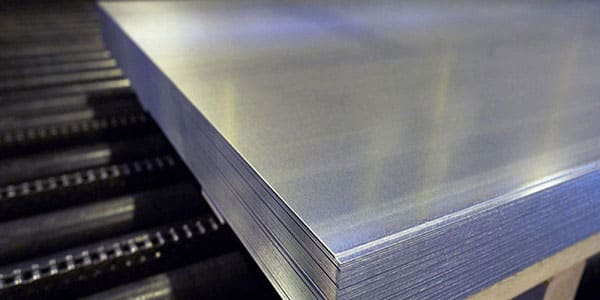

In the world of metal manufacturing, 304 stainless steel sheets stand out for their exceptional durability, versatility, and eco-friendly properties. This article unveils the sustainable manufacturing processes behind these high-quality sheets, exploring the innovative techniques employed by industry leaders like Xinguangyuan to produce corrosion-resistant, formable, and strong stainless steel products. From raw material selection to advanced surface finishing, we'll delve into the meticulous journey of creating 304 stainless steel sheets while highlighting their diverse applications and the industry's commitment to sustainability.

The Manufacturing Process: Crafting Premium 304 Stainless Steel Sheets

The production of 304 stainless steel sheets involves a series of carefully controlled steps, each contributing to the final product's exceptional quality and performance.

Raw Material Selection

The process begins with the careful selection of high-quality raw materials, primarily iron, chromium (18-20%), and nickel (8-10.5%). Trace amounts of other elements like carbon, manganese, and silicon are also included. These materials undergo rigorous quality checks to ensure they meet the required specifications for producing premium 304 stainless steel.

Melting and Refining

The raw materials are melted in an electric arc furnace, reaching temperatures up to 1700°C (3092°F). This extreme heat facilitates the uniform combination of various metals into a homogeneous molten alloy. After melting, the molten metal undergoes refining processes, such as degassing, to remove impurities and fine-tune the chemical composition.

Continuous Casting

The refined molten metal is then cast into semi-finished forms, such as slabs or billets, using a continuous casting process. This method ensures consistent quality by minimizing segregation and porosity, setting the foundation for high-performance stainless steel sheets.

Hot and Cold Rolling

The solidified slabs or billets undergo hot rolling, where they are reheated and passed through a series of rolling mills. This process reduces their thickness and imparts the desired shape and dimensions. Depending on the final specifications, the sheets may also undergo cold rolling at room temperature, further reducing thickness and enhancing surface quality and mechanical properties.

Annealing and Pickling

To relieve internal stresses and improve ductility and formability, the rolled sheets undergo annealing, a heat treatment process. This is followed by pickling, a chemical treatment that removes surface oxides and contaminants, ensuring a clean and corrosion-resistant surface.

Surface Finishing Expertise

Xinguangyuan excels in a wide range of surface processing techniques for 304 stainless steel sheets. Their expertise includes:

- Mirror polishing for a flawless reflective finish

- Frosting for a matte appearance

- Drawbenching for precise textures

- Glazing for a smooth luster

- Etching for custom patterns and designs

These capabilities allow Xinguangyuan to meet diverse aesthetic and functional requirements across industries, setting them apart in the competitive stainless steel market.

Rigorous Quality Control

Throughout the manufacturing process, stringent quality control measures are implemented to ensure that the 304 stainless steel sheets meet the highest standards. This includes regular inspections, testing for mechanical properties, and adherence to international standards such as ASTM A240, ISO 9001, and EN 10088.

Versatile Applications of 304 Stainless Steel Sheets

The exceptional properties of 304 stainless steel sheets make them suitable for a wide range of applications across various industries:

- Food and Beverage Industry: Kitchen equipment, sinks, countertops, appliances, and food processing machinery

- Architecture and Construction: Decorative panels, cladding, wall panels, and structural components

- Automotive and Transportation: Exhaust systems, trim pieces, and interior fixtures

- Medical and Pharmaceutical: Surgical instruments, medical equipment, and clean room components

- Chemical and Industrial Processing: Equipment, tanks, piping, and other components requiring corrosion resistance and high-temperature performance

Sustainable Manufacturing Practices

Xinguangyuan and other leading manufacturers in the industry are committed to sustainable practices throughout their operations:

100% Recyclable Material

304 stainless steel is fully recyclable, with its high scrap value ensuring that it is diverted from landfills and recaptured for use in new products. This closed-loop recycling process significantly reduces the environmental impact of stainless steel production.

Energy-Efficient Processes

Manufacturers continually invest in energy-efficient technologies and processes to reduce their carbon footprint. This includes optimizing furnace operations, implementing heat recovery systems, and utilizing renewable energy sources where possible.

Waste Minimization

Advanced manufacturing techniques and careful process control help minimize waste generation. Any scrap or byproducts are typically recycled or repurposed, further enhancing the sustainability of the production process.

Responsible Sourcing

Ethical sourcing of raw materials is a priority for sustainable manufacturers. This includes partnering with suppliers who adhere to environmental and social responsibility standards, ensuring a sustainable supply chain from start to finish.

Custom Stainless Steel Solutions

Xinguangyuan's innovative business model enables them to provide tailored 304 stainless steel solutions. They work closely with clients to develop custom specifications, from unique dimensions and thicknesses to specialized surface finishes. This flexibility in manufacturing allows them to meet the exacting needs of industries ranging from high-end architectural projects to precision medical equipment.

Industry Trends and Xinguangyuan's Innovations

The stainless steel industry is constantly evolving, driven by technological advancements and changing market demands. Xinguangyuan stays at the forefront of these trends:

Advanced Surface Finishing Techniques

Continuous innovation in surface finishing techniques, such as vibration finishing and advanced coatings, opens up new possibilities for enhancing the aesthetic and functional properties of stainless steel sheets.

Digital Technology Integration

The adoption of digital technologies, including automation, robotics, and advanced data analytics, is transforming the manufacturing process. This integration improves efficiency, quality control, and traceability while enabling more precise and consistent production.

Emphasis on Circular Economy

As environmental concerns grow, the industry is placing a stronger emphasis on the circular economy. This includes efforts to increase recycling rates, reduce energy consumption, and explore alternative manufacturing processes with lower environmental impact.

Customization Capabilities

Xinguangyuan's commitment to meeting diverse client needs is reflected in their ability to offer customized solutions, such as unique surface patterns or specialized material compositions tailored to specific applications.

Quality Control and Industry Standards

Ensuring the highest quality standards is paramount in the stainless steel industry. Xinguangyuan adheres to stringent quality control measures and international standards throughout the manufacturing process, including:

- ASTM A240 compliance for chemical composition and mechanical properties

- ISO 9001 certification for quality management systems

- EN 10088 adherence for technical delivery conditions

By maintaining these high standards, Xinguangyuan ensures that their 304 stainless steel sheets consistently meet or exceed customer expectations for quality and performance.

Conclusion

The journey through Xinguangyuan's 304 stainless steel sheet factory reveals a commitment to excellence, sustainability, and innovation. From the careful selection of raw materials to the advanced surface finishing techniques, every step of the manufacturing process is optimized to produce high-quality, versatile stainless steel sheets.

As the demand for sustainable and durable materials continues to grow across various industries, manufacturers like Xinguangyuan are well-positioned to meet these needs. Their focus on customization, quality control, and adherence to international standards ensures that clients receive products tailored to their specific requirements while benefiting from the inherent strengths of 304 stainless steel.

Whether you're an architect seeking corrosion-resistant cladding, a food industry professional in need of hygienic equipment, or an engineer working on cutting-edge medical devices, 304 stainless steel sheets from Xinguangyuan offer the perfect combination of strength, versatility, and sustainability. Embrace the future of metal manufacturing with Xinguangyuan's sustainably produced 304 stainless steel sheets, and discover how this remarkable material can elevate your next project to new heights of performance and durability.