Stainless steel is an essential material in various industries, from construction and automotive to medical and food processing. Among the numerous grades available, 409 stainless steel stands out for its unique properties and applications. In this comprehensive article, we'll delve into the intricacies of 409 stainless steel, exploring its composition, characteristics, and real-world applications.

Understanding 409 Stainless Steel

409 stainless steel, also known as ferritic stainless steel, is an alloy composed primarily of chromium (10.5-11.7%) and iron. Unlike austenitic stainless steels, it does not contain nickel, making it a more cost-effective option for applications where corrosion resistance is essential but high strength is not a primary requirement.

Key Properties and Advantages

- Corrosion Resistance: The chromium content in 409 stainless steel forms a passive layer that protects the material from corrosion, making it suitable for various environments, including mild atmospheric conditions and mildly corrosive media.

- Formability: 409 stainless steel exhibits excellent formability, allowing for easy shaping and fabrication processes such as stamping, drawing, and roll forming.

- Weldability: This grade of stainless steel can be readily welded using conventional techniques, making it suitable for applications that require welded assemblies.

- Magnetic Properties: Unlike austenitic stainless steels, 409 stainless steel is ferromagnetic, which can be advantageous in certain applications where magnetic properties are desirable.

- Cost-Effectiveness: As mentioned earlier, the absence of nickel in its composition makes 409 stainless steel a more economical choice compared to austenitic grades, while still providing adequate corrosion resistance.

Applications of 409 Stainless Steel

Due to its unique combination of properties, 409 stainless steel finds applications in various industries, including:

1. Automotive Industry

409 stainless steel is widely used in the automotive industry for components such as exhaust systems, mufflers, and catalytic converters. Its corrosion resistance and formability make it an ideal choice for these applications, ensuring durability and ease of manufacturing.

2. Kitchen Appliances and Utensils

The food-grade properties and corrosion resistance of 409 stainless steel make it a popular choice for kitchen appliances, cookware, and utensils. Its ability to withstand exposure to moisture, acidic foods, and cleaning agents ensures a long service life and easy maintenance.

3. Construction and Architecture

In the construction and architectural sectors, 409 stainless steel is used for various applications, including roofing, cladding, and decorative elements. Its corrosion resistance and attractive appearance make it a suitable choice for both functional and aesthetic purposes.

4. Medical and Pharmaceutical Industries

The biocompatibility and corrosion resistance of 409 stainless steel make it suitable for certain medical and pharmaceutical applications, such as surgical instruments, equipment housings, and processing equipment for pharmaceuticals.

Surface Finishing and Fabrication

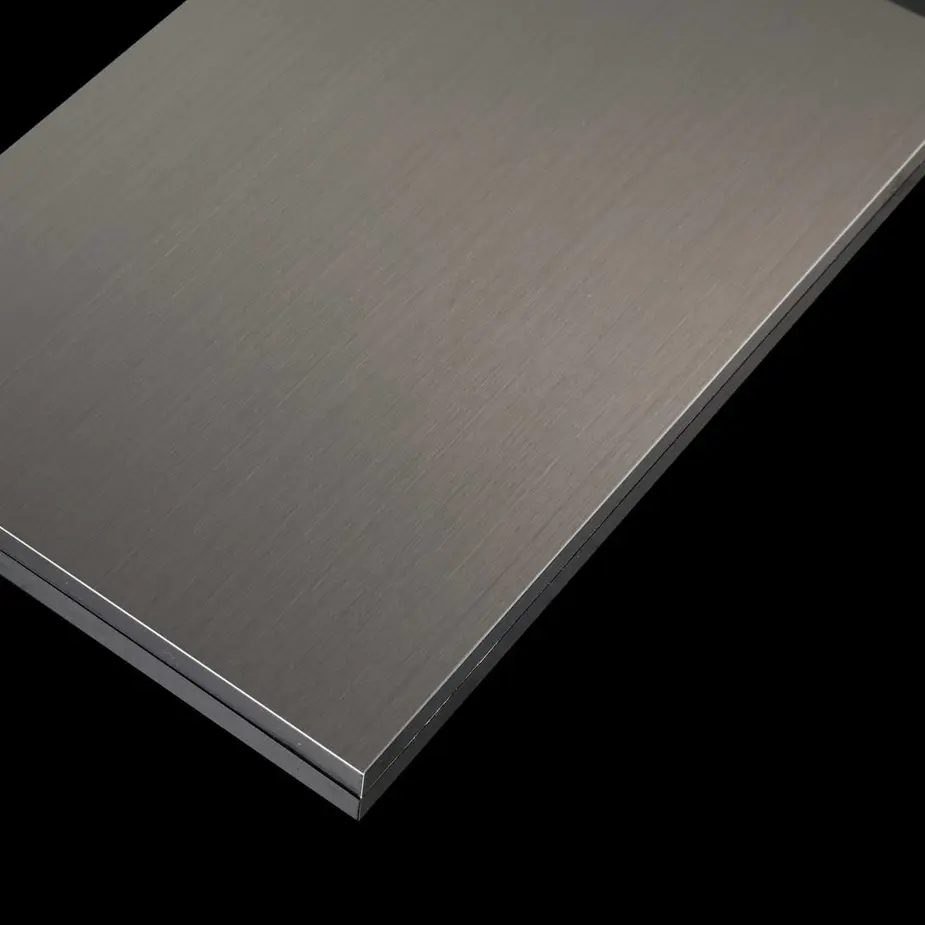

409 stainless steel can be finished in various ways to enhance its appearance and performance. Common surface finishing techniques include:

- Polishing: Polishing can create a smooth, reflective surface that is aesthetically pleasing and easy to clean.

- Brushing: Brushing creates a directional, matte finish that can be used for decorative purposes or to improve slip resistance.

- Bead Blasting: Bead blasting creates a uniform, matte finish that can improve corrosion resistance and provide a non-slip surface.

Regarding fabrication, 409 stainless steel can be processed using various techniques, including:

- Stamping: This grade of stainless steel can be easily stamped into complex shapes and forms.

- Roll Forming: Roll forming is a continuous bending process that can produce long, curved profiles from flat sheets of 409 stainless steel.

- Welding: As mentioned earlier, 409 stainless steel can be readily welded using conventional techniques, making it suitable for fabricating welded assemblies.

Comparison with Other Stainless Steel Grades

To better understand the unique characteristics of 409 stainless steel, it's helpful to compare it with other commonly used grades:

| Grade | Composition | Corrosion Resistance | Strength | Formability | Cost |

|---|---|---|---|---|---|

| 304 | Austenitic (Cr, Ni) | Excellent | High | Good | Higher |

| 316 | Austenitic (Cr, Ni, Mo) | Excellent (better than 304) | High | Good | Highest |

| 430 | Ferritic (Cr) | Good | Moderate | Excellent | Low |

| 409 | Ferritic (Cr) | Good | Moderate | Excellent | Low |

As the table illustrates, 409 stainless steel offers a balance between corrosion resistance, formability, and cost-effectiveness, making it a suitable choice for applications where these factors are prioritized over high strength requirements.

Frequently Asked Questions (FAQs)

1. Can 409 stainless steel be used in harsh environments?

While 409 stainless steel offers good corrosion resistance, it may not be suitable for highly corrosive environments or applications involving exposure to strong acids or bases. In such cases, more corrosion-resistant grades like 316 stainless steel may be more appropriate.

2. Is 409 stainless steel magnetic?

Yes, 409 stainless steel is ferromagnetic, meaning it can be attracted to magnets. This property can be advantageous in certain applications where magnetic properties are desirable.

3. Can 409 stainless steel be welded?

Yes, 409 stainless steel can be readily welded using conventional techniques such as gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW). However, proper welding procedures and filler materials should be used to ensure optimal weld quality and corrosion resistance.

4. Is 409 stainless steel suitable for high-temperature applications?

409 stainless steel has moderate heat resistance and can be used in applications involving temperatures up to approximately 650°C (1200°F). However, for higher temperature applications, other grades like austenitic stainless steels may be more suitable.

5. How does 409 stainless steel compare to 304 stainless steel in terms of cost?

409 stainless steel is generally more cost-effective than 304 stainless steel due to the absence of nickel in its composition. This makes 409 stainless steel a more economical choice for applications where corrosion resistance is required but high strength is not a primary concern.

Conclusion

409 stainless steel is a versatile and cost-effective material that offers a unique combination of properties, including corrosion resistance, formability, and weldability. Its applications span various industries, from automotive and construction to kitchen appliances and medical equipment. By understanding its characteristics, fabrication techniques, and surface finishing options, manufacturers and engineers can leverage the benefits of 409 stainless steel to create durable, functional, and visually appealing products. Whether you're seeking a cost-effective solution for mild corrosive environments or a material that can be easily formed and welded, 409 stainless steel is an excellent choice worth considering.