Stainless steel is a versatile and widely used material known for its exceptional corrosion resistance, durability, and aesthetic appeal. Among the various grades of stainless steel, 410 stainless steel coil stands out as a popular choice for numerous applications. This comprehensive guide will explore the properties, applications, and manufacturing processes of 410 stainless steel coil, providing valuable insights for those seeking to understand this remarkable material.

What is 410 Stainless Steel Coil?

410 stainless steel is a martensitic grade of stainless steel that contains chromium (11-13.5%) and a moderate amount of carbon (0.08-0.15%). This composition gives 410 stainless steel its unique properties, including high strength, hardness, and moderate corrosion resistance.

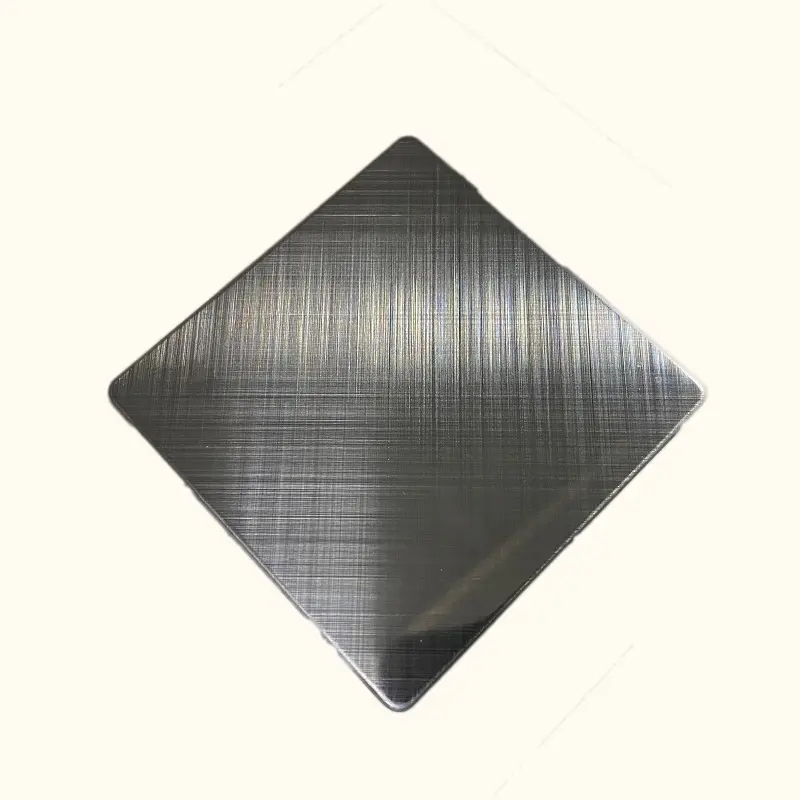

The coil form of 410 stainless steel is a continuous strip of metal that has been rolled into a cylindrical shape, making it convenient for transportation, storage, and further processing. These coils are available in various widths, thicknesses, and surface finishes, catering to the diverse needs of different industries.

Properties of 410 Stainless Steel Coil

Strength and Hardness

One of the standout features of 410 stainless steel is its high strength and hardness. This characteristic is attributed to the martensitic microstructure, which is formed through a specific heat treatment process. The high strength and hardness make 410 stainless steel coil suitable for applications that require wear resistance, such as cutting tools, bearings, and valve components.

Corrosion Resistance

While not as corrosion-resistant as some other stainless steel grades, 410 stainless steel coil offers moderate resistance to corrosion, particularly in mild environments. The chromium content in its composition forms a passive oxide layer that protects the material from corrosion. However, it is important to note that 410 stainless steel may be susceptible to pitting and crevice corrosion in more aggressive environments.

Magnetic Properties

Unlike austenitic stainless steels, 410 stainless steel is magnetic due to its martensitic microstructure. This property can be advantageous in applications where magnetic properties are desirable, such as in certain types of machinery or equipment.

Formability and Weldability

410 stainless steel coil exhibits good formability and weldability, making it suitable for various manufacturing processes, including stamping, bending, and welding. However, it is important to follow proper welding procedures and heat treatment methods to ensure optimal performance.

Applications of 410 Stainless Steel Coil

410 stainless steel coil finds applications in a wide range of industries due to its unique combination of properties. Some of the common applications include:

- Automotive Industry: Used in exhaust systems, suspension components, and various automotive parts due to its high strength and wear resistance.

- Cutlery and Knife Manufacturing: The hardness and edge retention properties of 410 stainless steel make it an ideal choice for knife blades and cutlery.

- Fasteners and Hardware: Utilized in the production of bolts, nuts, screws, and other hardware components that require high strength and moderate corrosion resistance.

- Machinery and Equipment: Employed in the manufacturing of gears, shafts, bearings, and other mechanical components that operate under demanding conditions.

- Decorative Applications: The attractive appearance of 410 stainless steel coil, combined with its corrosion resistance, makes it suitable for decorative applications, such as architectural trim and accents.

Manufacturing Process of 410 Stainless Steel Coil

The manufacturing process of 410 stainless steel coil involves several steps, each contributing to the final product's quality and performance. Here's a brief overview of the process:

-

Melting and Casting: The raw materials, including chromium, carbon, and other alloying elements, are melted in a furnace and cast into ingots or continuous cast slabs.

-

Hot Rolling: The ingots or slabs are heated and then passed through a series of rolling mills to reduce their thickness and shape them into coils or plates.

-

Annealing: The hot-rolled coils or plates undergo an annealing process, which involves heating and controlled cooling to refine the microstructure and improve the material's properties.

-

Cold Rolling: The annealed coils or plates are further reduced in thickness through a cold rolling process, which enhances the material's strength and surface finish.

-

Heat Treatment: To achieve the desired martensitic microstructure and hardness, the cold-rolled coils undergo a specific heat treatment process, which involves heating and quenching.

-

Surface Finishing: Depending on the application requirements, the coils can undergo various surface finishing processes, such as polishing, pickling, or applying specialized coatings.

-

Quality Control: Throughout the manufacturing process, strict quality control measures are implemented to ensure that the 410 stainless steel coil meets the required specifications and industry standards.

Surface Finishes and Treatments

410 stainless steel coil can be further enhanced through various surface finishes and treatments, tailored to meet specific application requirements. Some common surface finishes and treatments include:

-

Mirror Finish: A highly reflective and smooth surface achieved through specialized polishing techniques, suitable for decorative applications and environments where cleanliness is crucial.

-

Bead Blasting: A process that creates a uniform matte finish by bombarding the surface with small glass or ceramic beads, providing a non-reflective and slip-resistant surface.

-

Etching: A chemical or electrochemical process that creates intricate patterns or textures on the surface, often used for decorative purposes or to improve adhesion for coatings.

-

Passivation: A chemical treatment that enhances the corrosion resistance of stainless steel by promoting the formation of a protective oxide layer on the surface.

-

Coatings: Various coatings, such as PVD (Physical Vapor Deposition) or electroplating, can be applied to 410 stainless steel coil to improve its appearance, wear resistance, or corrosion resistance.

By selecting the appropriate surface finish or treatment, manufacturers can tailor the properties of 410 stainless steel coil to meet the specific requirements of their applications.

Sustainability and Recycling

Stainless steel, including 410 stainless steel coil, is a highly sustainable and recyclable material. The recycling process for stainless steel involves melting and reprocessing scrap or end-of-life products, significantly reducing the need for new raw materials and minimizing environmental impact.

Xinguangyuan, as a responsible manufacturer, prioritizes sustainable practices and promotes the recycling of stainless steel products. By choosing 410 stainless steel coil from reputable suppliers like Xinguangyuan, customers can contribute to a more sustainable future while benefiting from the exceptional properties of this remarkable material.

Conclusion

410 stainless steel coil is a versatile and high-performance material that offers a unique combination of strength, hardness, moderate corrosion resistance, and magnetic properties. Its diverse applications span various industries, including automotive, cutlery, fasteners, machinery, and decorative applications. By understanding the properties, manufacturing processes, and surface finishing options of 410 stainless steel coil, manufacturers and end-users can make informed decisions and leverage this remarkable material to its fullest potential.

Xinguangyuan, as a leading supplier of stainless steel products, is committed to providing high-quality 410 stainless steel coil solutions tailored to meet the specific needs of its customers. With a focus on sustainability, innovation, and customer satisfaction, Xinguangyuan continues to be a trusted partner in the stainless steel industry.

For more information or to explore the wide range of stainless steel products offered by Xinguangyuan, visit their website or contact them directly.