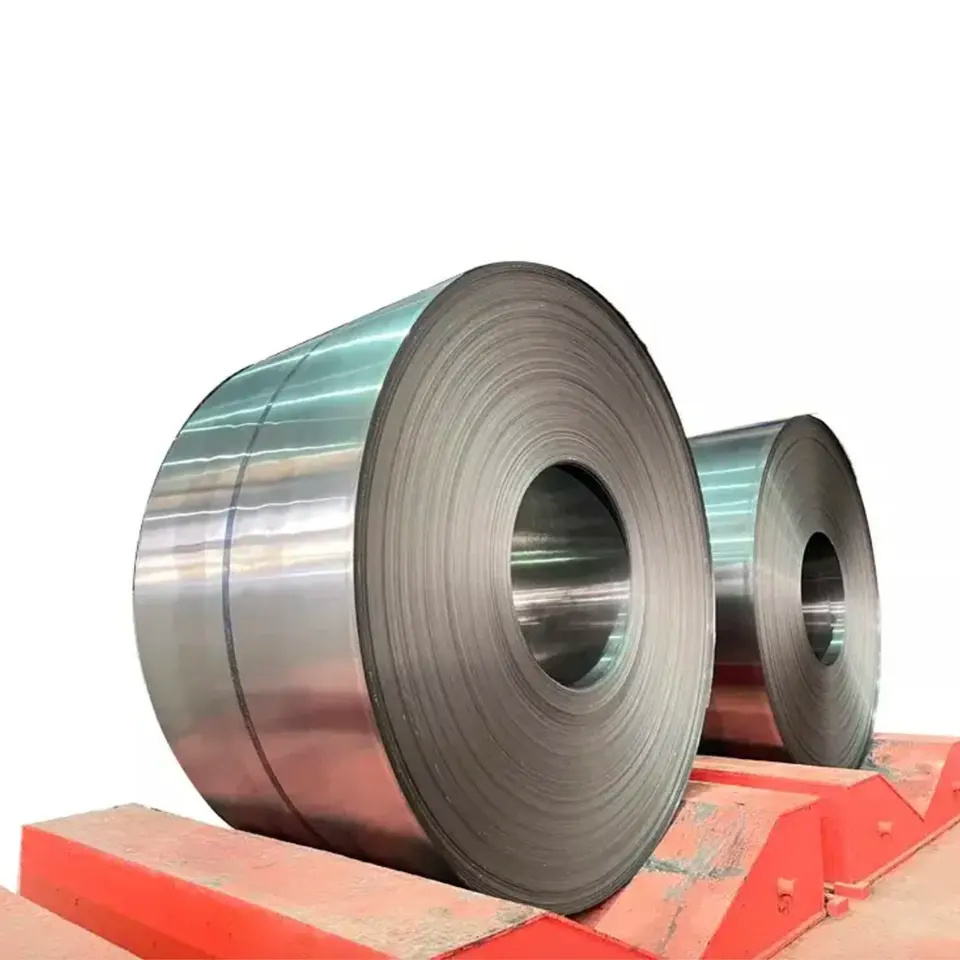

Xinguangyuan Stainless Steel Co., Ltd. is a leading manufacturer of high-quality 430 stainless steel coils, providing comprehensive solutions for diverse industries. With our state-of-the-art facilities and commitment to excellence, we deliver superior 430 stainless steel products that meet the most demanding requirements.

Understanding 430 Stainless Steel

430 stainless steel is a versatile and cost-effective ferritic grade known for its excellent corrosion resistance and durability. Containing 16-18% chromium, this alloy forms a protective passive layer that shields it from oxidation and corrosion. Its balanced composition also includes ≤0.12% carbon, ≤1.0% silicon, ≤1.0% manganese, ≤0.04% phosphorus, ≤0.03% sulfur, and ≤0.75% nickel, resulting in a material with outstanding properties.

Key features of 430 stainless steel include:

- Good corrosion resistance, especially in oxidizing environments

- Excellent formability and weldability

- Moderate strength and hardness

- Magnetic properties

- Affordability compared to other stainless grades

These characteristics make 430 stainless steel coils an ideal choice for a wide range of applications across various industries.

Xinguangyuan's Expertise in 430 Stainless Steel Manufacturing

At Xinguangyuan, we specialize in producing top-quality 430 stainless steel coils using advanced manufacturing processes and strict quality control measures. Our skilled technicians and state-of-the-art facilities enable us to deliver consistent, reliable products that exceed customer expectations.

Our manufacturing capabilities include:

- Precision rolling and leveling for optimal flatness and thickness tolerance

- Various surface finishes, such as 2B, BA, No.4, and mirror polishing

- Customized dimensions and specifications to meet specific requirements

- Large-scale production capacity of 300,000 tonnes per year

By leveraging our expertise and innovative technologies, we ensure that our 430 stainless steel coils deliver exceptional performance and value for our customers.

Diverse Applications of 430 Stainless Steel

The versatility of 430 stainless steel coils makes them suitable for a broad spectrum of applications across industries:

- Automotive: Exhaust systems, trim, and decorative components

- Appliances: Kitchen appliances, white goods, and HVAC equipment

- Construction: Roofing, cladding, and architectural elements

- Food processing: Equipment, utensils, and storage containers

- Medical devices: Surgical instruments and equipment

- Industrial: Chemical processing equipment, heat exchangers, and tanks

Xinguangyuan's 430 stainless steel coils provide the perfect combination of corrosion resistance, formability, and affordability for these demanding applications.

Ensuring Quality and Sustainability

At Xinguangyuan, quality control and sustainability are at the core of our operations. We implement rigorous testing and inspection procedures throughout the manufacturing process to guarantee the highest standards of quality and performance.

Our quality control measures include:

- Strict raw material selection and verification

- In-process monitoring and testing

- Final product inspection and certification

- Compliance with international standards (ASTM, EN, JIS, GB)

In addition to quality, we are committed to sustainable practices that minimize our environmental impact. 430 stainless steel is inherently eco-friendly and 100% recyclable, contributing to a circular economy.

Customization and Value-Added Services

Xinguangyuan understands that every customer has unique requirements. That's why we offer a wide range of customization options and value-added services to ensure that our 430 stainless steel coils meet your specific needs.

Our customization capabilities include:

- Tailored chemical composition and mechanical properties

- Customized dimensions, tolerances, and surface finishes

- Small batch production for specialized applications

We also provide comprehensive technical support, logistics management, and after-sales service to ensure a seamless experience for our customers.

Why Choose Xinguangyuan for 430 Stainless Steel Coils?

Xinguangyuan is your trusted partner for high-quality 430 stainless steel coils. With our extensive expertise, advanced manufacturing capabilities, and commitment to quality and sustainability, we deliver superior products and services that drive your success.

Key reasons to choose Xinguangyuan:

- Proven track record of excellence in 430 stainless steel manufacturing

- State-of-the-art facilities and skilled workforce

- Strict quality control and sustainable practices

- Customization options and value-added services

- Reliable and responsive customer support

Contact Xinguangyuan today to discuss how our comprehensive 430 stainless steel coil solutions can elevate your manufacturing operations to new heights. Our dedicated team is ready to assist you in finding the perfect products for your specific requirements.

Frequently Asked Questions

Q: What is the chemical composition of 430 stainless steel? A: 430 stainless steel typically contains 16-18% chromium, ≤0.12% carbon, ≤1.0% silicon, ≤1.0% manganese, ≤0.04% phosphorus, ≤0.03% sulfur, and ≤0.75% nickel.

Q: What are the key properties of 430 stainless steel? A: 430 stainless steel offers good corrosion resistance, excellent formability and weldability, moderate strength and hardness, magnetic properties, and affordability compared to other stainless grades.

Q: What industries commonly use 430 stainless steel coils? A: 430 stainless steel coils find applications in the automotive, appliance, construction, food processing, medical device, and industrial sectors.

Q: How does Xinguangyuan ensure the quality of its 430 stainless steel coils? A: Xinguangyuan implements strict quality control measures, including raw material selection, in-process monitoring, final product inspection, and compliance with international standards.

Q: Can Xinguangyuan customize 430 stainless steel coils to specific requirements? A: Yes, Xinguangyuan offers customization options for chemical composition, mechanical properties, dimensions, tolerances, and surface finishes to meet customers' unique needs.

For more information about Xinguangyuan's 430 stainless steel coils and how they can benefit your manufacturing operations, please visit our website or contact our sales team today.