Are you considering purchasing stainless steel coils? If so, you've come to the right place. This comprehensive guide will provide you with valuable insights and practical tips to make an informed decision.

Understanding Stainless Steel Coils

Stainless steel coils are versatile materials used in various industrial applications, including the manufacturing of automotive parts, kitchen appliances, and medical equipment. With over 60 stainless steel grades and numerous products to choose from, it can be challenging to select the right coil for your project.

Key Factors to Consider When Buying Stainless Steel Coils

When choosing stainless steel coils, several factors should be taken into account to ensure the product meets your expectations.

Corrosion Resistance

The installation environment is a crucial factor for stainless steel products. Depending on the atmospheric conditions, concentration levels of specific chemicals, and acidity, you may need to choose a specific stainless steel grade. For less corrosive environments, an austenitic stainless steel grade for general purposes is suitable. However, for highly acidic environments, you might need to opt for a stainless steel grade like 316, 904L, or 2205.

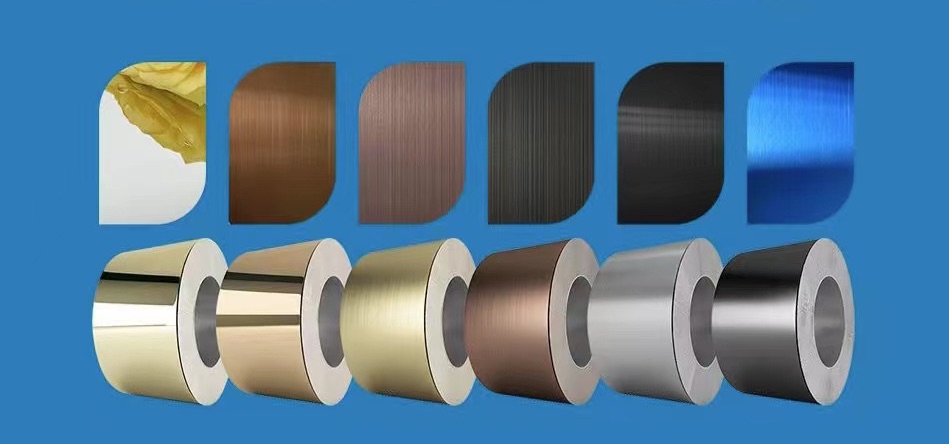

PVD Color Stainless Steel Coil

Heat Resistance

The temperature of the environment is also an important factor. In high-temperature environments (900-1175°C), the corrosion of stainless steel accelerates, putting extra pressure on the products. If the temperature is consistently high, you need heat-resistant stainless steel, such as 321 and 253MA.

Cryogenic Resistance

Very low temperatures are another factor to consider. Austenitic stainless steels are effective at very low temperatures, maintaining higher tensile strength at low temperatures than at ambient temperatures.

Magnetic Response

Austenitic grades have a low magnetic response, while those with higher nickel content, such as the 316 or 310 grades, are not magnetic under any conditions. On the other hand, ferritic and martensitic stainless steel grades (400 series) are highly permeable.

Strength Required

The strength required for your application is an important factor to consider before choosing the grade. High strength stainless steels, like austenitic and duplex, are suitable for some cases, but their disadvantages may not meet your requirements in other scenarios.

.jpg)

NO.8 Mirror Stainless Steel Coil Suppliers

Form of Product

Stainless steel products come in various forms, such as sheets, bars, and tubes. The form will affect the grade you need. Not all grades have all product forms and sizes. Austenitic stainless steels are very versatile, while ferritic steels generally appear in sheet form, and martensitic steels are common in solid bar form.

Special Requirements

When installing stainless steel products, there may be some special requirements that may necessitate a change in the grade of steel. For example, you may need non-magnetic steel, products suitable for welding, products with a high degree of forming, or simply a good-looking product.

Cost

Cost is always a factor when choosing to buy stainless steel coil. You need to balance it with all the other considerations. Sometimes the best technical steel may be too expensive. However, remember to assess the cost on a life cycle basis. Stainless steel products have a long life, so a high cost for high-quality steel is reasonable.

How to Determine the Quality of Stainless Steel Coils

Determining the quality of stainless steel coils is crucial. Here are two methods to test the quality of your stainless steel coil:

The Magnet Test

The "magnet test" is a simple method to check whether the steel is austenitic or whether the steel contains chromium and nickel. Simply take a magnet to your stainless steel coil. If the magnet sticks, the coil is safe because it indicates no nickel in the steel. But if the magnet doesn’t stick, it means the steel contains nickel, so the coil may not be safe for food usage.

.jpg)

Material Tester

A material tester can help distinguish between 201 stainless steel, 202 stainless steel, and 304 stainless steel. By applying a corrosive liquid to the stainless steel coil and observing the color change, you can determine the type of stainless steel.

Choosing Between 304 and 316 Stainless Steel

When deciding between 304 and 316 stainless steel, consider the environment in which you will operate. The higher performance of 316 stainless steel comes with a higher price, but it may be necessary depending on your needs. For example, 316 stainless steel is more suitable for marine applications and seawater environments due to its greater resistance to oxidations.

Conclusion

Selecting the right stainless steel coil involves considering several factors, including corrosion resistance, heat resistance, cryogenic resistance, magnetic response, required strength, product form, special requirements, and cost. By understanding these factors and using the right testing methods, you can ensure that you choose the right stainless steel coil for your needs. If you need further assistance, don't hesitate to contact our professional team at XINGUANGYUAN. We're here to help you make the best decision for your project.