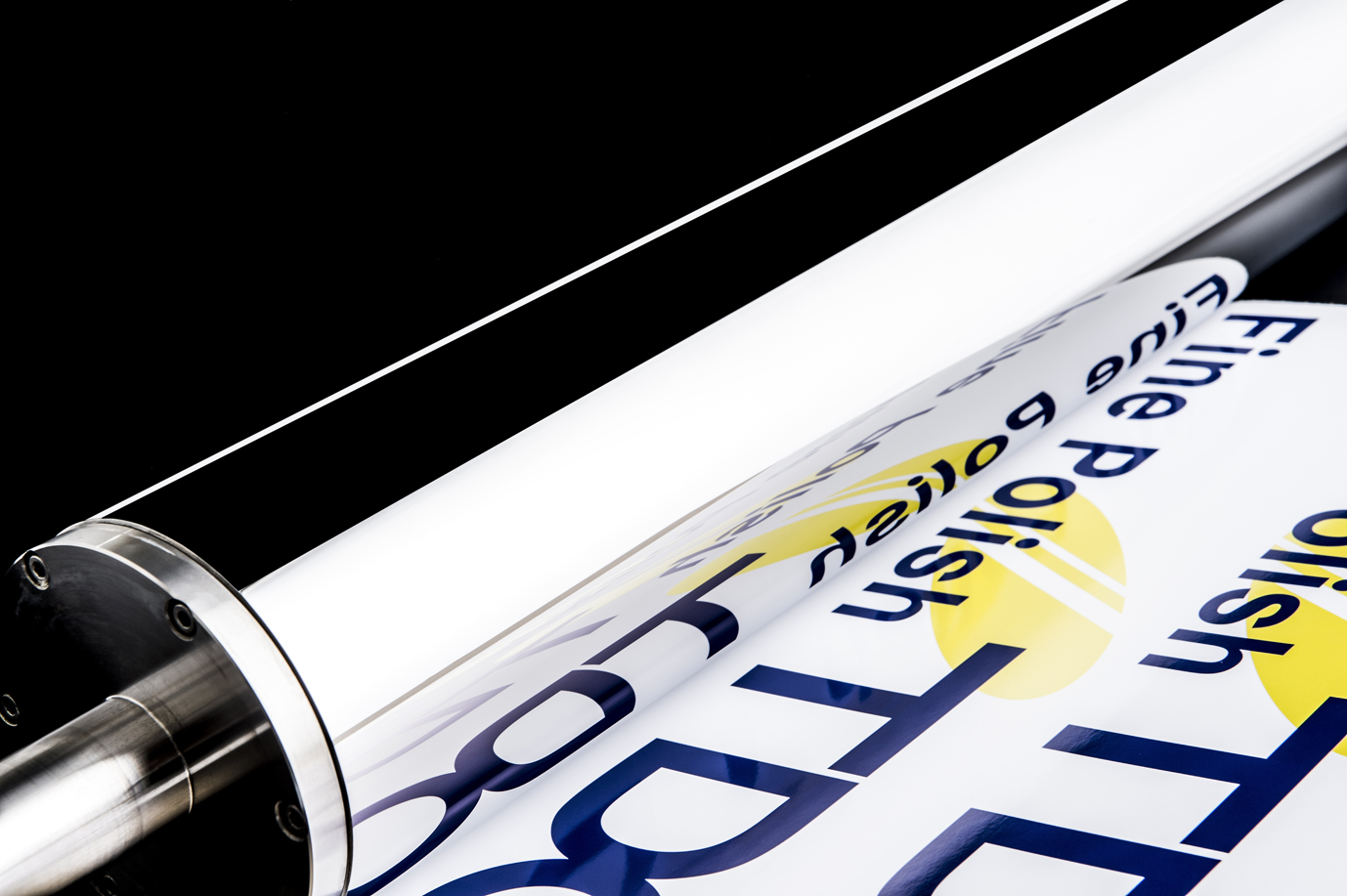

The #8 mirror polish is the pinnacle of stainless steel surface finishes, renowned for its flawless, highly reflective appearance. Achieving this level of polish involves a meticulous process of grinding, sanding, and buffing, methodically removing surface imperfections until a mirror-like sheen emerges. This guide will walk you through the step-by-step process of mastering the #8 mirror polish, enabling you to create stunning, reflective surfaces that are both aesthetically pleasing and durable.

Understanding the #8 Mirror Polish

The #8 mirror polish is the highest level of polish for stainless steel, characterized by its exceptional reflectivity and smoothness. It is achieved through a multi-stage process involving grinding, sanding, and buffing, which progressively removes imperfections to create a flawless, mirror-like finish. This finish is highly valued for its aesthetic appeal and durability, making it a popular choice in industries such as architecture, automotive design, and high-end appliance manufacturing.

Mastering the #8 polish demands dedication and a deep understanding of the techniques and tools involved. While labor-intensive, the breathtaking results make it a highly sought-after finish in industries such as architecture, automotive design, and high-end appliance manufacturing.

Preparing the Stainless Steel Surface

Before diving into the polishing process, it's crucial to properly prepare the stainless steel surface. This involves several key steps:

-

Cleaning: Thoroughly clean the surface with a stainless steel-specific cleaner to remove dirt, grease, and contaminants that could hinder polishing.

-

Degreasing: Apply a degreaser to eliminate any residual oils or grease that may interfere with the polishing process.

-

Inspecting for Imperfections: Meticulously inspect the surface for scratches, dents, or other imperfections. Mark these areas for extra attention during the grinding stage.

The Polishing Process: A Step-by-Step Guide

Achieving the perfect #8 mirror polish involves a multi-stage process, gradually progressing from coarse to fine abrasives and polishing compounds. Here's a breakdown of the steps:

-

Grinding: Use coarse grinding wheels (60-180 grit) to remove deep scratches, welds, and major surface imperfections. Progress from lower to higher grits.

-

Sanding: Once major imperfections are removed, sand the surface using progressively finer grits (220-2000) to achieve a smooth, scratch-free finish.

-

Polishing: Apply polishing compounds, starting with coarse and moving to finer compounds, using wheels or pads designed for stainless steel.

-

Final Buffing: Perform a final buffing with a rouge compound and soft pad to eliminate any remaining imperfections and enhance the mirror-like reflectivity.

Pro Tip: Invest in high-quality abrasives and polishing compounds specifically formulated for stainless steel to achieve the best results.

Throughout the process, work in a clean environment and use tools and materials designed for stainless steel polishing. Patience and attention to detail are paramount, as each step builds upon the previous to create the stunning #8 mirror finish.

Maintaining the Mirror Finish

To maintain the stunning appearance and longevity of your #8 mirror-polished stainless steel, follow these essential maintenance tips:

Regular Cleaning: Use a microfiber cloth and a mild stainless steel cleaner to wipe down the surface regularly, removing fingerprints and smudges. Avoid using abrasive cleaners or materials that could scratch the finish.

Preventing Scratches: Handle the mirror-finished surface with care to prevent scratches and dents. Place protective pads under heavy objects to safeguard the surface.

Polishing Touch-Ups: Periodically apply a fine polishing compound with a soft cloth to touch up areas that have lost their shine. Buff with a clean microfiber cloth to restore the mirror finish. Regular maintenance ensures the surface remains reflective and visually appealing over time.

Applications of Mirror-Finished Stainless Steel

The #8 mirror polish finds applications in various industries where aesthetics and durability are paramount:

-

Architecture and Interior Design: Mirror-finished stainless steel adds elegance to architectural elements like wall cladding, elevator interiors, and decorative accents.

-

Appliance Manufacturing: High-end kitchen appliances often feature mirror-finished stainless steel for a sleek, modern look.

-

Automotive Industry: Mirror-finished stainless steel enhances the aesthetic appeal of trim pieces, emblems, and decorative accents on vehicles.

-

Medical and Pharmaceutical Industries: The smooth, easily cleanable surface of mirror-finished stainless steel is ideal for medical equipment, surgical instruments, and pharmaceutical manufacturing environments.

-

Luxury Goods and Accessories: From high-end watches to designer furniture, mirror-finished stainless steel adds sophistication to luxury products.

Case Study: The Stunning Stainless Steel Sculpture

One remarkable example of the #8 mirror polish's impact is a monumental stainless steel sculpture created by a renowned artist. The sculpture's fluid, organic forms were meticulously polished to a flawless mirror finish, reflecting the surrounding environment and captivating viewers. The interplay of light and reflection on the sculpture's surface created an ever-changing, mesmerizing display, showcasing the true potential of mirror-finished stainless steel as an artistic medium.

Achieving the #8 mirror polish on stainless steel is a rewarding process that demands skill, patience, and attention to detail. By mastering this technique, you can transform ordinary stainless steel into stunning, reflective surfaces that are both aesthetically pleasing and durable. Whether you're working on architectural projects, luxury goods, or artistic sculptures, the #8 mirror polish offers a versatile and captivating finish that enhances any design. With the right tools and techniques, you can unlock the full potential of stainless steel and create mirror-like finishes that inspire and captivate.

Benefits of Mirror Finish Stainless Steel

In addition to its stunning appearance, mirror-finish stainless steel offers several practical benefits:

Easy Maintenance: The smooth surface of mirror-finish stainless steel is resistant to fingerprints and smudges, making it easy to clean and maintain. This property is particularly advantageous in industries where hygiene is critical, such as food processing and medical equipment manufacturing.

Corrosion Resistance: While the mirror finish itself does not enhance the inherent corrosion resistance of stainless steel, its smooth surface reduces the accumulation of contaminants, which can help maintain the material's durability over time.

Aesthetic Versatility: Mirror-finish stainless steel is versatile and can be used in a wide range of applications, from architectural elements to luxury goods, adding a touch of sophistication and elegance to any design.