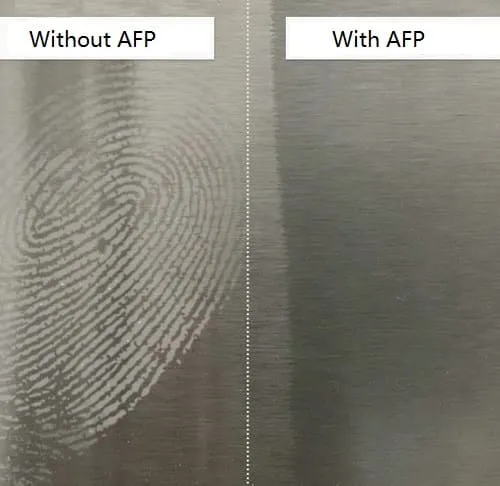

In today's world of sleek, modern design, stainless steel has become a go-to material for its durability, versatility, and timeless aesthetic appeal. However, one persistent challenge has been keeping those pristine surfaces free from unsightly fingerprints and smudges. Enter anti-fingerprint stainless steel sheets – an innovative solution that combines the strength and beauty of stainless steel with advanced coating technology to create a surface that actively repels prints and stains.

What are Anti-fingerprint Stainless Steel Sheets?

Anti-fingerprint stainless steel sheets feature a specialized coating that is applied to the surface of the steel. This coating, typically a transparent nano-metallic liquid, forms a hard, solid protective film when dried. The result is a stainless steel surface that resists the oils and residues left behind by fingerprints, making it exceptionally easy to clean and maintain a flawless appearance.

Key Benefits of Anti-fingerprint Stainless Steel:

- Repels fingerprints, smudges, and stains

- Enhances surface durability and scratch-resistance

- Preserves the natural luster and grain of the stainless steel

- Simplifies cleaning and maintenance

- Suitable for a wide range of applications and finishes

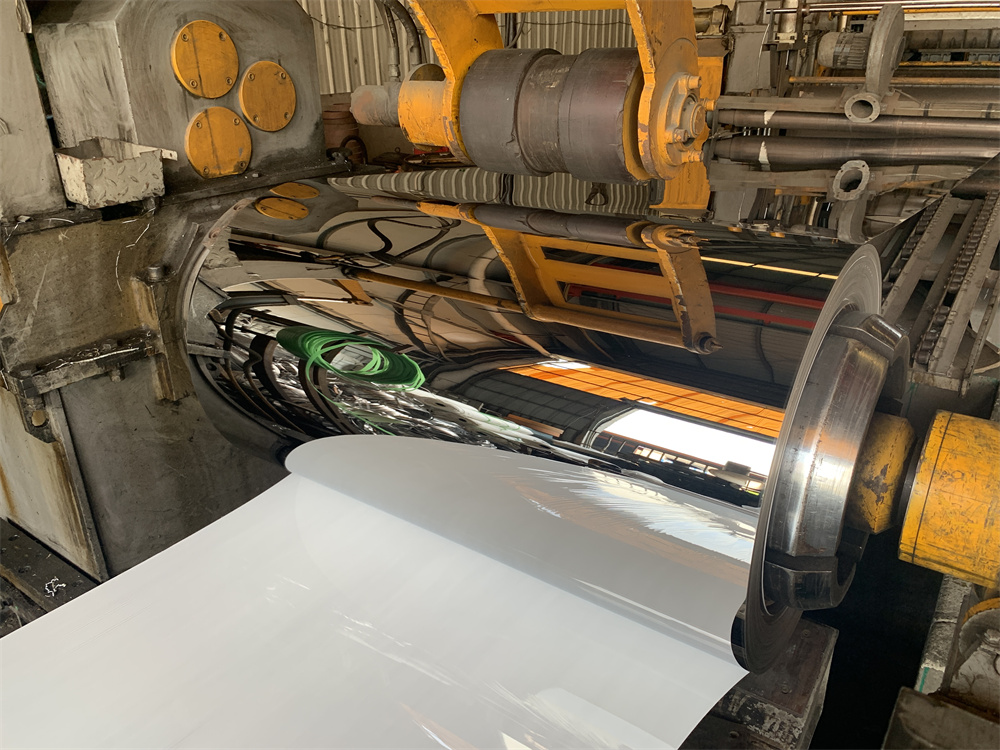

How are Anti-fingerprint Stainless Steel Sheets Made?

The manufacturing process for anti-fingerprint stainless steel sheets involves several critical steps:

-

Surface Preparation: The stainless steel surface is thoroughly cleaned to remove any contaminants and create an ideal base for the coating.

-

Nano-Scale Surface Treatment: Advanced techniques are used to create a nano-scale texture on the surface of the steel. This microscopic roughness is key to the fingerprint-resistant properties.

-

Coating Application: The anti-fingerprint coating, usually a transparent nano-metallic liquid, is applied evenly across the prepared surface.

-

Curing Process: The coated sheets are exposed to carefully controlled temperatures to cure and harden the protective film, ensuring optimal durability and adhesion.

-

Inspection and Testing: Rigorous quality control measures are employed to verify the performance and consistency of the anti-fingerprint coating.

This meticulous process results in a stainless steel surface that actively repels fingerprints and smudges, while maintaining the inherent strength, beauty, and versatility of the underlying steel.

Advantages of Anti-fingerprint Stainless Steel

Beyond its core fingerprint-resistant properties, anti-fingerprint stainless steel offers a range of compelling benefits:

Enhanced Durability

The hard, protective coating not only repels prints but also increases the surface's resistance to scratches, abrasions, and general wear. This makes anti-fingerprint stainless steel an ideal choice for high-traffic, heavy-use applications where maintaining a pristine appearance is paramount.

Simplified Maintenance

With anti-fingerprint stainless steel, cleaning is a breeze. The fingerprint-resistant coating means that any marks or smudges that do occur can be easily wiped away with a soft cloth, without the need for harsh chemicals or abrasives. This saves time and effort in keeping surfaces looking their best.

Preserves Natural Beauty

Unlike some surface treatments that can alter the appearance of stainless steel, anti-fingerprint coatings are virtually invisible. They preserve the natural luster, color, and grain of the steel, allowing the inherent beauty of the material to shine through.

Versatile Aesthetics

Anti-fingerprint coatings can be applied to a wide range of stainless steel finishes, from sleek mirror-polish to textured brushed surfaces. This versatility allows designers and architects to achieve the perfect look for any project, without sacrificing performance.

Applications for Anti-fingerprint Stainless Steel

The practical benefits and aesthetic appeal of anti-fingerprint stainless steel make it a smart choice for a diverse array of applications, including:

- Architectural and Design: Elevators, escalators, handrails, door hardware, interior panels, and decorative features.

- Food Service and Hospitality: Kitchen equipment, countertops, serving stations, and public fixtures in restaurants, hotels, and cafeterias.

- Healthcare and Laboratories: Medical devices, equipment housings, work surfaces, and high-touch areas in hospitals, clinics, and research facilities.

- Consumer Appliances: Refrigerators, dishwashers, ovens, microwaves, and other home appliances where fingerprints are a constant battle.

- Transportation: Interior and exterior components in automobiles, trains, buses, and aircraft where maintaining a clean, professional appearance is critical.

As technology continues to advance, the potential applications for anti-fingerprint stainless steel are only expected to grow, offering new opportunities to create surfaces that are as functional as they are beautiful.

The Future of Anti-fingerprint Stainless Steel

The demand for anti-fingerprint stainless steel is poised for significant growth in the coming years, driven by several key factors:

- Increasing consumer preference for easy-to-clean, low-maintenance surfaces in homes and public spaces.

- Growing awareness of hygiene and the desire to minimize the spread of contaminants via high-touch surfaces.

- Continued advancement in coating technologies, enhancing performance and durability.

- Expansion into new and emerging markets, such as consumer electronics and transportation.

As a leading innovator in this space, Xinguangyuan is committed to staying at the forefront of anti-fingerprint stainless steel technology. Our team of experts is constantly pushing the boundaries to develop new and improved coatings that deliver unparalleled performance, durability, and aesthetics.

Frequently Asked Questions

How durable is the anti-fingerprint coating?

Anti-fingerprint coatings are engineered to be highly durable, withstanding regular cleaning and resisting scratches and abrasions. With proper care, the coating can last for many years without losing its fingerprint-resistant properties.

Can anti-fingerprint stainless steel be welded or formed?

Yes, anti-fingerprint stainless steel can be welded, bent, and formed using standard fabrication techniques. The coating is applied after any welding or forming to ensure a seamless, uniform finish.

Is anti-fingerprint stainless steel more expensive?

While anti-fingerprint stainless steel does carry a premium over standard stainless, the long-term benefits of reduced maintenance and extended service life often make it a cost-effective choice. The exact price difference will depend on the specific grade and finish of the steel.

How do I clean anti-fingerprint stainless steel?

Cleaning anti-fingerprint stainless steel is quick and easy. Simply wipe the surface with a soft, dry or slightly damp cloth to remove any marks or smudges. Avoid using abrasive pads or harsh chemicals that could damage the coating.

Discover the Advantages of Anti-fingerprint Stainless Steel

Ready to experience the benefits of anti-fingerprint stainless steel for your next project? Contact Xinguangyuan today to learn more about our innovative coating solutions and how we can help you achieve smudge-free surfaces that are as beautiful as they are practical. Our team of experts is standing by to answer your questions and guide you through the specification process.

Let us show you why Xinguangyuan is the trusted choice for anti-fingerprint stainless steel performance and innovation. Visit our website or call +86 0757-29 269678 to get started.