Black Mirror Stainless Steel Coils are transforming the architectural landscape with their sleek, modern aesthetic and superior durability. These coils, characterized by their reflective black finish, are not only visually striking but also offer a range of practical benefits, making them an ideal choice for various architectural applications. This article delves into the features, manufacturing processes, applications, and sustainability aspects of Black Mirror Stainless Steel Coils, providing a comprehensive guide for architects and designers.

Features and Benefits

Aesthetic Appeal

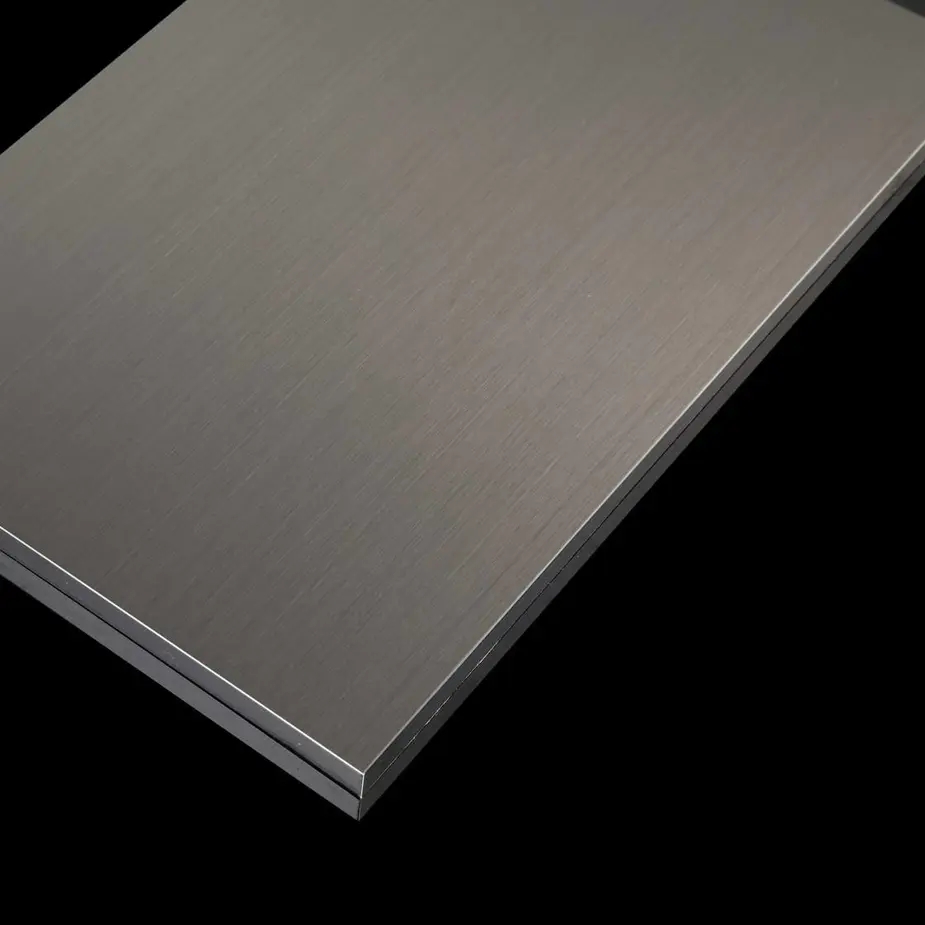

The Black Mirror Stainless Steel Coil boasts a high-gloss, mirror-like finish that adds a touch of elegance and sophistication to any architectural project. This finish is achieved through advanced coating technologies, such as Physical Vapor Deposition (PVD), which enhances the surface hardness and wear resistance of the stainless steel, ensuring a long-lasting, visually appealing product.

Durability and Resistance

One of the standout features of Black Mirror Stainless Steel Coils is their exceptional durability. The PVD coating not only provides a stunning black finish but also significantly improves the material's resistance to corrosion, oxidation, and wear. This makes these coils suitable for both interior and exterior applications, where they can withstand harsh environmental conditions without losing their luster.

Versatility

Black Mirror Stainless Steel Coils are available in various grades, including 201, 304, and 316, each offering different levels of corrosion resistance and mechanical properties. This versatility allows architects to choose the most suitable grade for their specific project requirements, whether it be for decorative trim, elevator doors, wall panels, or signage.

Manufacturing Process

The production of Black Mirror Stainless Steel Coils involves several key steps to ensure the highest quality and performance. Here is an overview of the manufacturing process:

Melting and Casting

The process begins with melting raw materials, including recycled stainless steel and ferroalloys, in an electric arc furnace. The molten metal is then transferred to a converter, where alloying elements are added to achieve the desired chemical composition. The liquid steel is then cooled and solidified during the continuous casting process, forming slabs that are ready for further processing.

Hot Rolling

The slabs are reheated in a furnace and passed through a series of rolling stands to reduce their thickness. This hot rolling process not only shapes the steel but also enhances its mechanical properties. The resulting coils, known as "black coils" due to their oxidized surface, are then shipped to the annealing and pickling plant for further treatment.

Cold Rolling and Annealing

In the cold rolling stage, the black coils are further reduced in thickness and given a smoother surface finish. The coils are then annealed in a controlled atmosphere to restore their ductility and achieve the desired mechanical properties. This step is crucial for ensuring the flatness and surface quality of the final product.

Surface Finishing

The final step involves applying the PVD coating to achieve the black mirror finish. This process involves depositing a thin film of titanium or other metals onto the stainless steel surface in a vacuum chamber. The result is a highly reflective, durable, and corrosion-resistant finish that meets the highest standards of quality and aesthetics.

Applications in Architecture

Black Mirror Stainless Steel Coils are highly versatile and can be used in a wide range of architectural applications. Here are some of the most common uses:

Interior Decoration

The sleek, reflective surface of Black Mirror Stainless Steel Coils makes them an excellent choice for interior decoration. They can be used for wall panels, ceilings, furniture, and decorative trim, adding a modern and luxurious touch to any space.

Exterior Facades

Thanks to their durability and resistance to corrosion, Black Mirror Stainless Steel Coils are also ideal for exterior facades. They can withstand harsh weather conditions and maintain their aesthetic appeal over time, making them a popular choice for high-end architectural projects.

Elevator Doors and Panels

The high-gloss finish of Black Mirror Stainless Steel Coils is perfect for elevator doors and panels, where a sophisticated and modern look is desired. The material's resistance to wear and fingerprints ensures that it remains pristine even with frequent use.

Signage and Decorative Elements

Black Mirror Stainless Steel Coils can be used to create striking signage and decorative elements that stand out and make a statement. Their reflective surface enhances visibility and adds a touch of elegance to any design.

Sustainability

Recyclability

Stainless steel is one of the most sustainable materials available, thanks to its recyclability. Black Mirror Stainless Steel Coils can be recycled without losing their properties, making them an environmentally friendly choice for architectural projects. This contributes to a circular economy and reduces the environmental impact of construction.

Long Service Life

The durability and resistance of Black Mirror Stainless Steel Coils ensure a long service life, reducing the need for frequent replacements and maintenance. This not only saves costs but also minimizes the environmental impact associated with the production and disposal of building materials.

Energy Efficiency

The production of stainless steel, including Black Mirror Stainless Steel Coils, has become increasingly energy-efficient. Advances in manufacturing processes and recycling technologies have reduced the energy consumption and greenhouse gas emissions associated with stainless steel production, making it a more sustainable choice for architects and builders.

Market Trends

Growing Demand in Construction

The demand for stainless steel in the construction industry is on the rise, driven by its durability, aesthetic appeal, and sustainability. Black Mirror Stainless Steel Coils are particularly popular in high-end architectural projects, where their unique finish and superior performance make them a preferred choice.

Technological Advancements

Advances in coating technologies, such as PVD, have expanded the capabilities of stainless steel, allowing for the creation of new finishes and colors. These innovations are driving the adoption of Black Mirror Stainless Steel Coils in various architectural applications, as designers seek to create visually stunning and durable structures.

Focus on Sustainability

As the construction industry moves towards more sustainable practices, the use of recyclable and durable materials like stainless steel is becoming increasingly important. Black Mirror Stainless Steel Coils offer a sustainable solution that meets the demands of modern architecture while minimizing environmental impact.

Quality Control and Standards

Ensuring the highest quality and performance of Black Mirror Stainless Steel Coils requires strict adherence to international standards and rigorous quality control measures. Here are some key aspects of quality control in the manufacturing process:

Material Testing

Each batch of stainless steel undergoes thorough testing to ensure it meets the required chemical composition and mechanical properties. This includes tests for tensile strength, hardness, and corrosion resistance, among others.

Surface Inspection

The surface of the stainless steel coils is inspected for any defects or imperfections that could affect the final product's appearance and performance. This includes checking for scratches, dents, and other surface irregularities.

Coating Quality

The PVD coating process is carefully monitored to ensure a uniform and high-quality finish. This involves controlling the deposition parameters, such as temperature and pressure, to achieve the desired thickness and adhesion of the coating.

Conclusion

Black Mirror Stainless Steel Coils offer a unique combination of aesthetic appeal, durability, and sustainability, making them an ideal choice for a wide range of architectural applications. From interior decoration to exterior facades, these coils provide a modern and sophisticated look that enhances the overall design of any project. With their superior performance and environmentally friendly properties, Black Mirror Stainless Steel Coils are set to play a significant role in the future of architecture.

For more information on how to incorporate Black Mirror Stainless Steel Coils into your next project, visit our product page or contact our support team.