Stainless steel is one of the most widely used materials in industries ranging from construction to interior design. One of the most popular finishes for stainless steel sheets is the brushed finish, known for its modern, sleek appearance and practical benefits. This guide will explore the qualities of brushed stainless steel, its common applications, and how to choose the best brushed finish stainless steel sheet manufacturers for your needs.

What is Brushed Finish Stainless Steel?

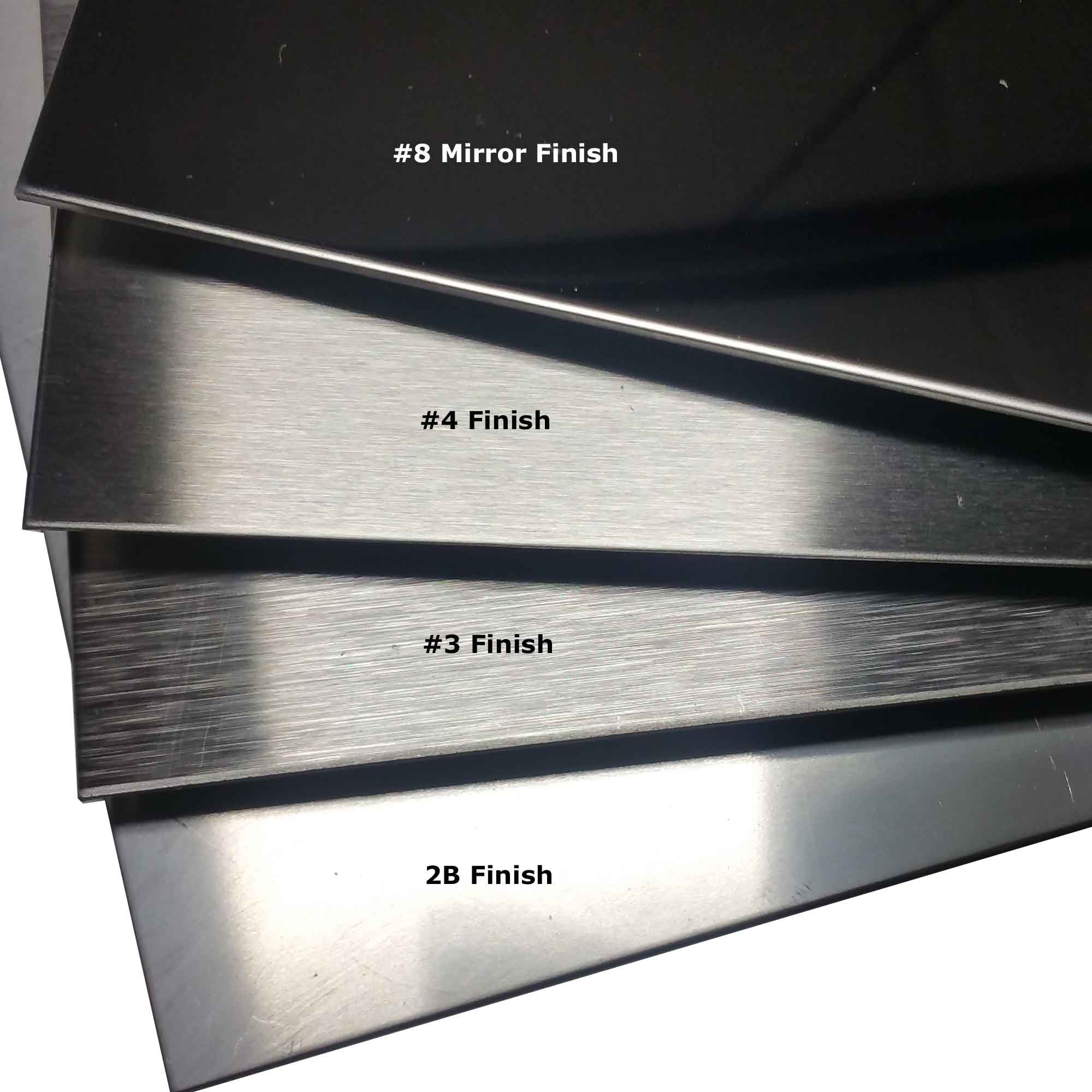

A brushed finish refers to a specific surface treatment applied to stainless steel sheets, where the metal is polished using fine abrasive brushes. This process creates a textured, matte appearance with fine lines running in one direction across the surface. It’s a visually appealing option that reduces the visibility of fingerprints and smudges, making it popular for both aesthetic and functional purposes.

Key Characteristics of Brushed Finish Stainless Steel Sheets:

- Texture: The brushed finish creates a linear pattern, which adds texture to the surface.

- Aesthetic Appeal: The matte look gives a sophisticated, modern feel, making it a favorite in architectural design.

- Durability: Despite its matte appearance, stainless steel with a brushed finish remains strong and corrosion-resistant.

- Smudge Resistance: The brushed surface is less prone to showing fingerprints and stains, making it ideal for high-traffic areas.

Benefits of Choosing Brushed Finish Stainless Steel Sheets

Using brushed finish stainless steel sheets offers numerous advantages, particularly in environments where appearance and durability are equally important.

1. Aesthetic Appeal

The brushed finish provides a subtle shine that’s less reflective than polished stainless steel, making it suitable for contemporary designs. Its sleek appearance is widely used in kitchens, commercial spaces, and interior designs, adding a touch of elegance without overpowering the surrounding decor.

2. Easy Maintenance

One of the main reasons brushed stainless steel is favored in high-traffic or commercial areas is its ability to hide fingerprints, smudges, and scratches. This reduces the need for constant cleaning, making it more practical than polished finishes for everyday use.

3. Durability

Brushed finish stainless steel retains all the inherent benefits of stainless steel, including its durability, corrosion resistance, and strength. This makes it ideal for both indoor and outdoor applications, ensuring long-term performance in various environments.

4. Versatility

Whether used for architectural panels, kitchen appliances, or industrial equipment, brushed finish stainless steel sheets are versatile and adaptable to many design requirements. They can be found in elevators, escalators, and even furniture design.

Common Applications of Brushed Finish Stainless Steel Sheets

Due to its combination of aesthetic appeal and practical benefits, brushed finish stainless steel sheets are widely used in a variety of industries and projects.

1. Kitchen Appliances

Refrigerators, dishwashers, ovens, and other kitchen appliances often use brushed finish stainless steel for its clean, modern look and resistance to fingerprints.

2. Elevator Interiors

Elevators are high-traffic areas where the sleek and durable properties of brushed stainless steel shine. The finish helps maintain a clean look despite frequent use.

3. Architectural Panels

For exterior or interior cladding, brushed stainless steel provides a durable yet stylish material that enhances the building's aesthetic. It’s commonly used in commercial buildings and public spaces.

4. Furniture and Interior Design

Designers often incorporate brushed stainless steel into modern furniture, lighting fixtures, and decorative elements due to its clean lines and resistance to wear and tear.

5. Automotive and Transport

Brushed finish stainless steel is also used in automotive applications, such as in the interior panels and trims of high-end vehicles, where its appearance and durability are key considerations.

How to Choose the Best Brushed Finish Stainless Steel Sheet Manufacturers

When selecting the right brushed finish stainless steel sheet manufacturer, it’s important to ensure that the supplier can meet your specific requirements in terms of quality, availability, and customization. Here are the main factors to consider:

1. Product Quality

Look for manufacturers who adhere to international standards such as ISO 9001 certification to ensure consistent product quality. Check if they offer stainless steel sheets in the grades (such as 304, 316, or 430) that match your application’s requirements.

2. Customization Capabilities

Some projects may require specific sizes, thicknesses, or finishes. Ensure that the manufacturer you choose offers customization options to meet your project’s needs.

3. Competitive Pricing

While price should not be the sole determining factor, it’s important to find a manufacturer that offers competitive pricing without compromising on the quality of the brushed finish stainless steel sheets.

4. Reputation and Experience

Choose a manufacturer with a solid track record in the industry. Check their reviews, testimonials, or case studies to ensure they have experience in supplying brushed finish stainless steel sheets for similar projects.

5. Delivery and Logistics

Timely delivery is critical for any project. Make sure the manufacturer has a reliable distribution network and can meet your delivery deadlines, especially if you require large quantities or international shipping.

Leading Brushed Finish Stainless Steel Sheet Manufacturers

Below are some of the leading brushed finish stainless steel sheet manufacturers known for their product quality, reliability, and customer service:

1. POSCO

As one of the largest steel manufacturers in the world, POSCO offers a wide range of stainless steel products, including brushed finish stainless steel sheets. They are known for their high-quality materials and global distribution network.

2. Jindal Stainless

Jindal Stainless is one of the largest manufacturers of stainless steel in India, providing brushed finish stainless steel sheets to clients worldwide. Their products meet international quality standards and are known for their durability and aesthetic appeal.

3. Outokumpu

Outokumpu is a global leader in stainless steel manufacturing. Their brushed finish stainless steel sheets are highly regarded for their corrosion resistance, strength, and sleek appearance. They cater to various industries, including construction, automotive, and appliance manufacturing.

4. Foshan Hermes Steel Co., Ltd.

Foshan Hermes Steel is a professional manufacturer and exporter of stainless steel sheets with a wide range of finishes, including brushed. They offer customization options and provide high-quality products at competitive prices.

5. Aperam

Aperam is a global player in the stainless steel industry, offering a variety of finishes including brushed. They focus on innovation and sustainability, producing stainless steel sheets that meet both aesthetic and performance requirements.

Conclusion

Choosing high-quality brushed finish stainless steel sheet manufacturers is essential for ensuring that your project benefits from durable, attractive, and easy-to-maintain materials. Whether you’re designing a kitchen, constructing a commercial building, or outfitting an elevator, brushed finish stainless steel offers an ideal combination of beauty and practicality.

When selecting a manufacturer, consider factors such as product quality, customization capabilities, reputation, and pricing. With the right partner, you can ensure that your brushed stainless steel sheets meet both your functional and aesthetic needs, providing long-lasting performance and a sleek, modern appearance.

Invest in brushed finish stainless steel sheets today to elevate the quality and style of your projects!