Xinguangyuan, a leading manufacturer of stainless steel products, offers high-quality customized embossed stainless steel coils that combine durability, affordability, and versatility. These coils feature unique surface patterns that enhance both aesthetics and functionality, making them ideal for a wide range of applications across various industries.

The Xinguangyuan Advantage

Xinguangyuan has established itself as an industry leader in stainless steel manufacturing, specializing in custom-made products for over a decade. Our expertise in creating personalized stainless steel solutions, including embossed coils, sets us apart from competitors. We leverage advanced technologies and sustainable practices to deliver products that meet the highest quality standards while remaining cost-effective.

Understanding Embossed Stainless Steel Coils

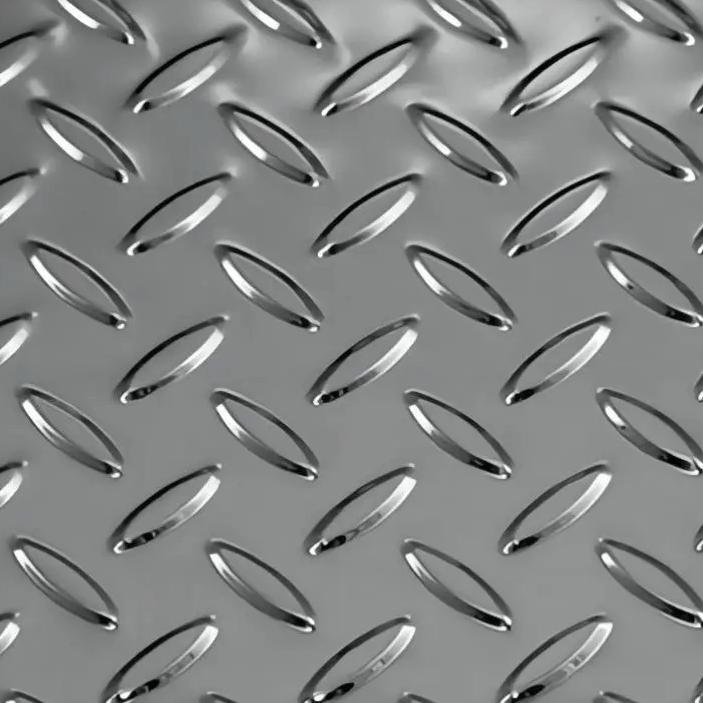

Embossed stainless steel coils are continuous sheets of stainless steel that have been processed to create raised patterns on their surface. This embossing process not only enhances the visual appeal of the material but also improves its functional properties.

Key features of our embossed stainless steel coils:

- Customizable patterns and designs

- Enhanced durability and scratch resistance

- Improved light diffusion and reduced glare

- Increased rigidity without added weight

- Superior corrosion resistance

Manufacturing Process

Our state-of-the-art manufacturing process ensures consistent quality and precision in every embossed stainless steel coil:

-

Material Selection: We use high-grade stainless steel, typically grades 304 or 316, known for their excellent corrosion resistance and durability.

-

Surface Preparation: The stainless steel sheets undergo thorough cleaning and polishing to create an ideal base for embossing.

-

Embossing: Using advanced roller technology, we imprint the desired pattern onto the stainless steel surface with precision and consistency.

-

Quality Control: Each coil undergoes rigorous inspection to ensure it meets our strict quality standards and client specifications.

-

Finishing: Depending on client requirements, additional treatments such as coloring or coating may be applied.

Versatile Applications

Customized embossed stainless steel coils from Xinguangyuan find applications across numerous industries:

- Architecture and Construction: Facade cladding, interior wall panels, elevator interiors

- Automotive: Decorative trim, body panels

- Appliances: Refrigerator doors, dishwasher panels

- Hospitality: Hotel decor, restaurant fixtures

- Industrial: Equipment enclosures, machine guards

- Healthcare: Medical device casings, hospital furnishings

Sustainability and Environmental Benefits

At Xinguangyuan, we prioritize sustainability in our manufacturing processes. Our embossed stainless steel coils offer several environmental advantages:

- 100% Recyclable: Stainless steel can be recycled indefinitely without loss of quality, reducing waste and conserving resources.

- Long Lifespan: The durability of stainless steel minimizes the need for replacements, lowering long-term environmental impact.

- Energy Efficiency: Our production methods incorporate energy-saving technologies to reduce carbon footprint.

- Low Maintenance: The corrosion resistance of stainless steel eliminates the need for harmful chemical treatments or frequent replacements.

Quality Assurance

Xinguangyuan maintains rigorous quality control measures throughout the production process:

- ISO 9001 Certified: Our quality management system ensures consistent product excellence.

- Material Testing: We conduct regular tests on raw materials and finished products to verify compliance with industry standards.

- Customized Quality Plans: We develop tailored quality assurance protocols for each client's specific requirements.

Affordability Without Compromise

Despite the premium quality of our embossed stainless steel coils, Xinguangyuan remains committed to offering competitive pricing. Our efficient production processes and economies of scale allow us to provide exceptional value without compromising on quality or customization options.

Customization Options

Xinguangyuan offers a wide range of customization options for embossed stainless steel coils:

- Pattern Selection: Choose from our extensive library of embossing patterns or work with our design team to create a unique design.

- Finish Options: Select from various surface finishes, including brushed, mirror-polished, or matte.

- Color Treatments: Explore our PVD color coating options for added aesthetic appeal.

- Size and Thickness: Customize coil dimensions to fit your specific project requirements.

Industry Trends and Innovations

Xinguangyuan stays at the forefront of industry trends, continuously innovating to meet evolving market demands:

- Advanced Surface Technologies: We're exploring new embossing techniques to create even more intricate and functional patterns.

- Smart Materials: Research into integrating smart technologies with embossed stainless steel for enhanced functionality.

- Sustainable Production: Ongoing efforts to further reduce environmental impact through process optimization and material innovations.

Conclusion

Xinguangyuan's customized embossed stainless steel coils offer an unparalleled combination of quality, affordability, and versatility. Our commitment to innovation, sustainability, and customer satisfaction positions us as a trusted partner for businesses across various industries. Whether you're an architect, manufacturer, or designer, our embossed stainless steel coils provide the perfect blend of form and function for your projects.

For more information on our products or to discuss your specific requirements, please visit our official website at www.xgystainlesssteel.com or contact our sales team directly.