Stainless steel is one of the most versatile materials used across industries due to its exceptional corrosion resistance, strength, and aesthetic qualities. While many focus on grades like 304 or 316, one often overlooked but critical factor is the surface finish of stainless steel sheets. The finish can determine how a sheet performs, looks, and ages—whether it’s used in a commercial kitchen, elevator interior, or architectural facade.

This article offers an in-depth look at the most common stainless steel sheet finishes, their characteristics, manufacturing processes, and appropriate applications—guiding you to choose the right finish for your project.

Why Stainless Steel Surface Finish Matters

The surface finish of stainless steel affects more than just its appearance. It influences:

-

Corrosion resistance: Certain finishes reduce surface roughness, minimizing corrosion initiation points.

-

Cleanability: Hygienic applications require smoother finishes that are easy to sanitize.

-

Reflectivity: In architecture or lighting design, the degree of reflection matters.

-

Friction and wear: Rough finishes can cause more abrasion or wear on moving parts.

-

Formability and weldability: Some finishes respond better to further fabrication.

Choosing the appropriate finish ensures that the stainless steel not only looks right but also performs reliably in its environment.

1. 2B Finish – Cold Rolled and Skin Passed

The 2B finish is the most commonly used surface for stainless steel sheets. It is produced by cold rolling, then annealing and pickling to remove scale. A final light pass on polished rolls gives it a uniform, matte appearance.

This finish is not highly reflective but is very smooth, making it ideal for industrial equipment, chemical processing vessels, and automated manufacturing systems. It strikes a balance between function and cost-effectiveness.

Because of its non-directional finish and ease of cleaning, 2B is also widely used in food processing and pharmaceutical environments where hygiene is critical.

2. No. 4 Finish – Brushed or Satin Finish

The No. 4 finish is achieved through mechanical polishing using abrasive belts, which create a distinct, linear texture. It’s the standard finish for appliances, kitchenware, and elevator panels due to its aesthetic appeal and ease of maintenance.

Unlike polished mirror surfaces, brushed stainless hides fingerprints and minor scratches, making it a preferred choice for high-traffic commercial settings. The subtle luster also makes it suitable for furniture accents, handrails, and interior cladding.

For architectural applications where a clean, professional look is desired, No. 4 offers both practicality and visual sophistication.

3. BA Finish – Bright Annealed

Bright annealed (BA) stainless steel undergoes cold rolling followed by annealing in a controlled atmosphere (usually hydrogen) to prevent oxidation. The result is a smooth, highly reflective surface with excellent flatness.

This finish is particularly popular for decorative trim, kitchen backsplashes, and electronic housings, where both appearance and corrosion resistance are important. While not as reflective as a No. 8 mirror, BA offers a clean and bright look with lower production costs.

BA stainless steel is also easier to form and weld, making it ideal for components that require further fabrication or bending.

4. No. 8 Finish – Mirror Finish

If ultimate reflectivity is the goal, No. 8 mirror finish is the standard. This finish involves multiple polishing steps to achieve a surface that is nearly flawless and highly reflective—comparable to a glass mirror.

Applications include:

-

Luxury interiors

-

High-end elevator doors

-

Art installations and public sculptures

-

Retail displays and signage

Its visual impact is unmatched, but it does require more maintenance due to its susceptibility to fingerprints and smudges. For designers prioritizing brilliance and elegance, No. 8 is the premium choice.

5. No. 1 Finish – Hot Rolled and Annealed

The No. 1 finish is a rough, mill-scale surface that results from hot rolling followed by annealing and descaling. It has a dull, uneven appearance and is not intended for aesthetic use.

It is typically used in industrial and structural applications where surface appearance is irrelevant, such as:

-

Heavy-duty tanks

-

Boiler plates

-

Support frames

-

Heat exchangers

This finish is highly durable and cost-effective, suitable for parts exposed to extreme mechanical stress or high temperatures.

6. Patterned and Textured Stainless Steel Finishes

To meet decorative demands, stainless steel sheets can be embossed, etched, bead-blasted, or patterned. These finishes combine form and function, offering enhanced slip resistance, reduced glare, or intricate visual effects.

Common uses include:

-

Public transport interiors

-

Exterior wall cladding

-

Designer furniture and signage

-

Custom commercial applications

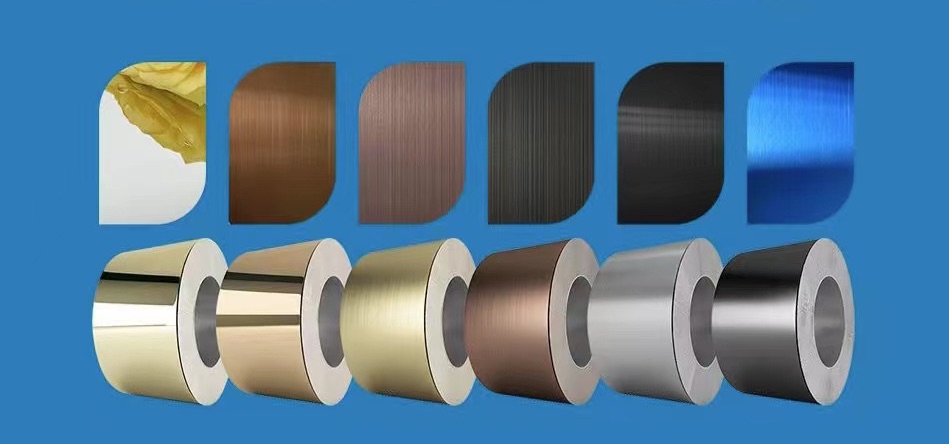

These finishes can also be layered with color treatments (like PVD coating) to create black, gold, or bronze stainless steel surfaces, greatly expanding creative possibilities.

How to Select the Right Finish for Your Needs

When choosing a finish, ask:

-

Where will the stainless steel be used? Indoor or outdoor, marine or dry environment?

-

Is hygiene critical? Smooth finishes like 2B or BA may be required.

-

Is appearance important? If aesthetics matter, choose No. 4, BA, or No. 8.

-

Will it undergo fabrication? Certain finishes respond better to bending, welding, or forming.

-

What’s your budget? Mirror and textured finishes cost more but offer greater visual impact.

Partner with a Trusted Stainless Steel Supplier: XINGUANGYUAN

Choosing the right finish is only part of the equation—partnering with an experienced stainless steel supplier ensures quality, consistency, and value.

XINGUANGYUAN is a reputable supplier of stainless steel coils and sheets in a full range of surface finishes, including:

-

Available in 304, 316, 201, and 430 grades

-

Precision cutting, surface protection, and custom size processing

-

Fast shipping and reliable global logistics

-

Tailored solutions for construction, kitchen equipment, decorative panels, and more

With a strong reputation for reliability and service, XINGUANGYUAN helps businesses worldwide meet both technical and aesthetic project requirements.

Contact XINGUANGYUAN today for expert guidance and competitive stainless steel solutions.

Conclusion

From industrial applications to high-end design, stainless steel sheet finishes play a key role in how materials function and look. Whether you need a clean and hygienic 2B surface or a striking mirror polish for interior design, understanding these finishes ensures you make the right choice.

With a supplier like XINGUANGYUAN, you gain access to top-quality materials, industry expertise, and exceptional customer service—all essential for project success.

FAQ: Frequently Asked Questions

Q1: What is the most commonly used stainless steel sheet finish?

A: The most commonly used finish is 2B, which offers a smooth, matte surface ideal for industrial, food-grade, and general-purpose applications due to its cleanability and corrosion resistance.

Q2: Which stainless steel finish is best for decorative use?

A: For decorative applications, the No. 8 mirror finish and BA bright annealed finish are most popular due to their reflective appearance. Patterned or colored stainless steel is also widely used in architectural design.

Q3: How do I choose between 2B and No. 4 finishes?

A: Choose 2B for clean, functional surfaces in industrial or hygienic settings. No. 4 is preferred when aesthetics matter, such as in kitchens or interiors, thanks to its brushed satin look that hides fingerprints.

Q4: Are stainless steel finishes only available in 304 grade?

A: No, finishes like 2B, No. 4, and BA are available in various grades including 304, 316, 201, and 430, each suited to different environments and corrosion resistance requirements.

Q5: Where can I buy high-quality stainless steel sheets with different finishes?

A: You can source premium stainless steel coils and sheets in multiple finishes from XINGUANGYUAN, a trusted global supplier known for quality materials, customization services, and competitive pricing.