Stainless steel is renowned for its corrosion resistance and durability, making it an ideal material for various applications. However, within the stainless steel family, there is a unique group known as duplex stainless steels that offer exceptional strength and corrosion resistance properties. This comprehensive guide will explore the world of duplex stainless steels, their properties, grades, and applications, providing valuable insights for engineers, manufacturers, and anyone interested in this versatile alloy.

What is Duplex Stainless Steel?

Duplex stainless steels are a class of stainless steels that combine the properties of both austenitic and ferritic stainless steels. They derive their name from their microstructure, which consists of approximately equal amounts of austenite and ferrite phases. This unique combination results in a material with superior mechanical strength, corrosion resistance, and stress corrosion cracking resistance compared to conventional austenitic or ferritic stainless steels.

Key Properties of Duplex Stainless Steels

-

High Strength: Duplex stainless steels exhibit yield strengths that are typically twice as high as austenitic stainless steels, such as 304 or 316. This increased strength allows for the use of thinner sections, resulting in weight savings and reduced material costs, making them an ideal choice for industries seeking lightweight yet durable solutions.

-

Excellent Corrosion Resistance: The high chromium content, along with the addition of molybdenum and nitrogen, provides duplex stainless steels with exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, even in harsh environments. This makes them suitable for applications in industries like oil and gas, chemical processing, and marine environments.

-

Low Thermal Expansion: Duplex stainless steels have a lower coefficient of thermal expansion compared to austenitic grades, making them suitable for applications where dimensional stability is crucial, such as in the aerospace and automotive industries.

-

Good Weldability: While welding duplex stainless steels requires careful control of heat input and cooling rates, they generally exhibit good weldability when proper procedures are followed, ensuring reliable and durable joints in fabricated structures.

Grades of Duplex Stainless Steels

Duplex stainless steels are available in various grades, each with its own unique composition and properties tailored to specific industry requirements. Here are some of the most common grades:

-

Lean Duplex Stainless Steels: These grades, such as 2101 and 2304, have lower alloying content and are often used in applications where moderate corrosion resistance and strength are required, such as in the construction industry for reinforcement bars, bridges, and buildings.

-

Standard Duplex Stainless Steels: The workhorse of the duplex family, grades like 2205 and 2507, offer a balanced combination of strength and corrosion resistance, making them suitable for a wide range of applications, including chemical processing, oil and gas, and marine environments. These grades are commonly used in equipment like reactors, heat exchangers, storage tanks, and offshore platforms.

-

Super Duplex Stainless Steels: Highly alloyed grades like 2507 and 2550 are designed for exceptional resistance to pitting and crevice corrosion in extremely aggressive environments, such as seawater and acidic conditions. These grades are often specified for applications in desalination plants, pulp and paper mills, and other corrosive industrial settings.

-

Hyper Duplex Stainless Steels: These grades, like 2707, represent the pinnacle of duplex stainless steel technology, offering unparalleled corrosion resistance and strength for the most demanding applications, such as in the nuclear industry, where extreme durability and safety are paramount.

Applications of Duplex Stainless Steels

Due to their unique properties, duplex stainless steels find applications in various industries:

-

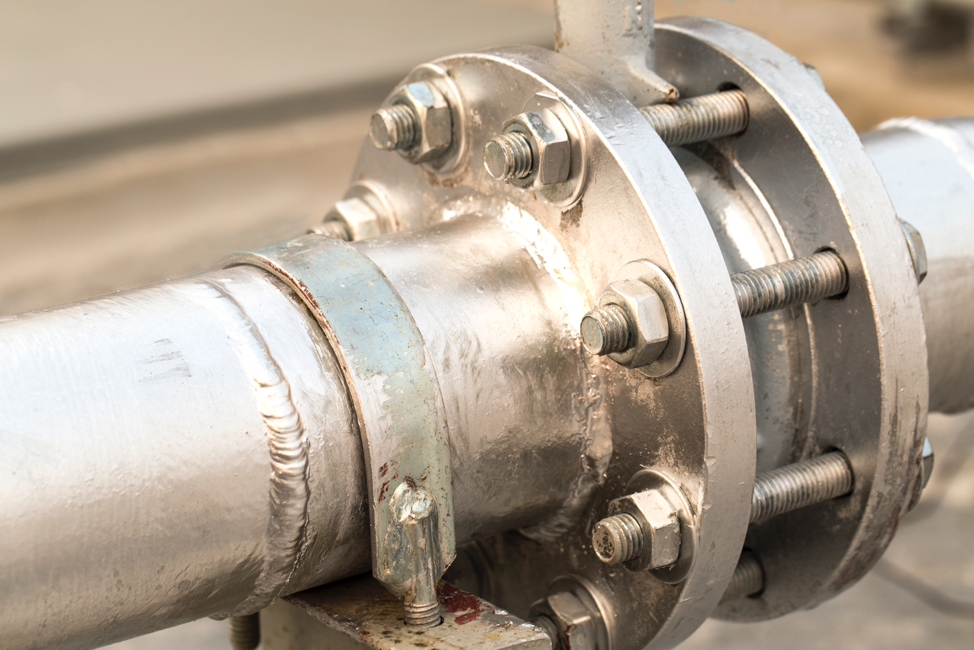

Oil and Gas: Duplex stainless steels are widely used in offshore platforms, pipelines, and processing equipment due to their resistance to corrosion and stress corrosion cracking in harsh marine environments. Their strength and durability make them ideal for critical components like risers, wellhead equipment, and subsea structures.

-

Chemical Processing: The excellent corrosion resistance of duplex stainless steels makes them ideal for use in chemical processing equipment, such as reactors, heat exchangers, and storage tanks, where they can withstand exposure to corrosive chemicals and harsh operating conditions.

-

Desalination and Water Treatment: The combination of strength and corrosion resistance makes duplex stainless steels a popular choice for desalination plants and water treatment facilities, where they are used in components like pumps, piping systems, and filtration equipment.

-

Pulp and Paper: The pulp and paper industry relies on duplex stainless steels for their resistance to the corrosive environments found in pulp digesters and bleaching equipment, ensuring reliable and long-lasting performance.

-

Construction and Architecture: Lean duplex grades are increasingly being used in construction projects, such as bridges, buildings, and reinforcement bars, due to their strength and durability, making them a cost-effective alternative to traditional materials.

-

Energy and Power Generation: Duplex stainless steels are used in power plants, nuclear reactors, and renewable energy systems, where their corrosion resistance and strength are essential for components like heat exchangers, condensers, and piping systems.

-

Medical and Pharmaceutical: The biocompatibility and corrosion resistance of duplex stainless steels make them suitable for medical and pharmaceutical applications, such as surgical instruments, implants, and processing equipment.

-

Transportation: The automotive and aerospace industries utilize duplex stainless steels for their strength-to-weight ratio and dimensional stability, making them ideal for components like suspension systems, exhaust systems, and structural components.

-

Consumer Products: Duplex stainless steels are also used in various consumer products, such as kitchen appliances, cookware, and decorative hardware, where their durability and aesthetic appeal are valued.

Xinguangyuan: Your Partner for Duplex Stainless Steel Solutions

At Xinguangyuan, we specialize in providing high-quality duplex stainless steel products and solutions tailored to the unique requirements of various industries. Our expertise spans a wide range of surface processing techniques, including mirror surface processing, frosting, drawbenching, glazing, and etching, ensuring that our products meet the highest standards of durability, corrosion resistance, and aesthetic appeal.

Our product offerings include decorative plates, screens, and garnitures in different specifications, catering to industries such as kitchen appliances, medical devices, elevator decoration, doors, hotel decoration, and hardware. With our commitment to innovation and customer satisfaction, we strive to deliver solutions that not only meet but exceed our clients' expectations.

Explore our range of duplex stainless steel products and surface processing capabilities, or contact our experts to discuss your specific requirements.

Conclusion

Duplex stainless steels offer a unique combination of properties that make them an attractive choice for a wide range of applications across various industries. Their high strength, exceptional corrosion resistance, and low thermal expansion make them a versatile material for industries where durability and performance are paramount. As technology continues to advance, the development of new duplex stainless steel grades with improved properties will further expand their applications and solidify their position as a material of choice for demanding environments.