When it comes to surface finishes, bead blasting is a popular technique that offers numerous benefits and applications across various industries. Whether you're a seasoned professional or simply curious about the process, keep reading this article and know about the bead blast finish.

What Is Bead Blast Finish?

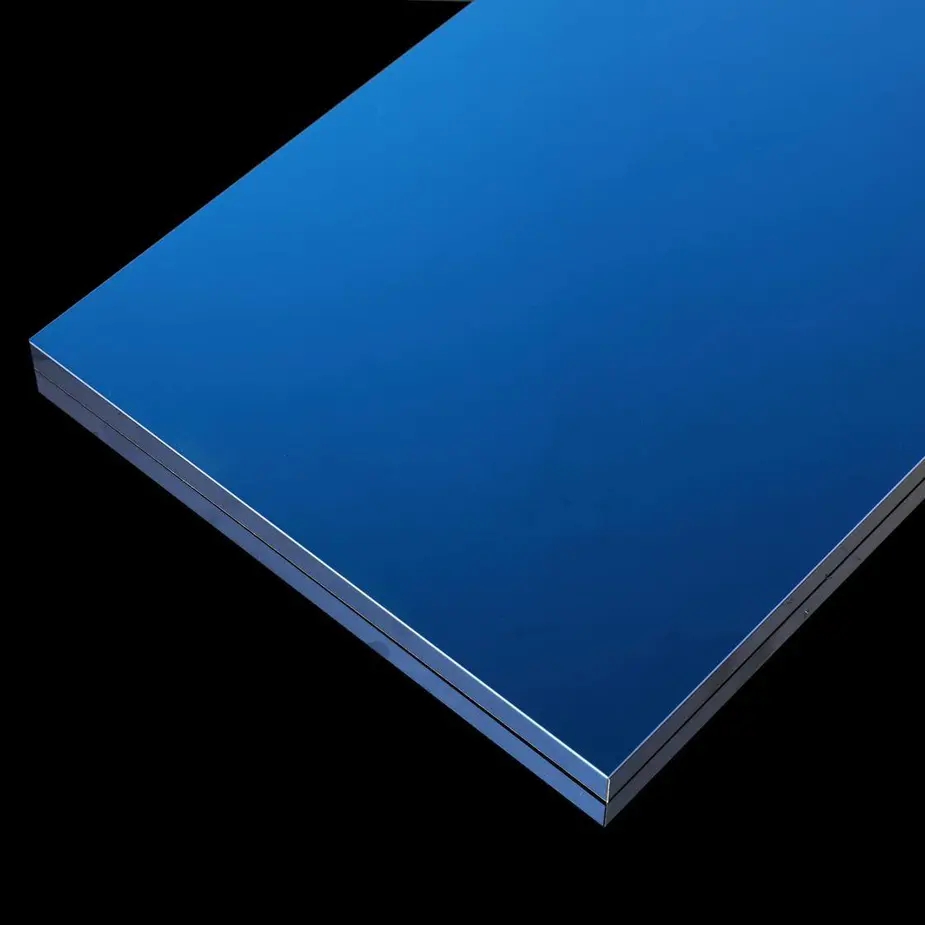

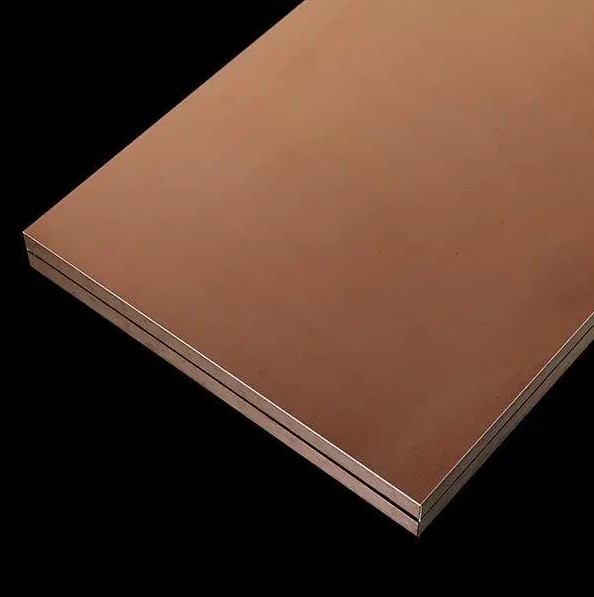

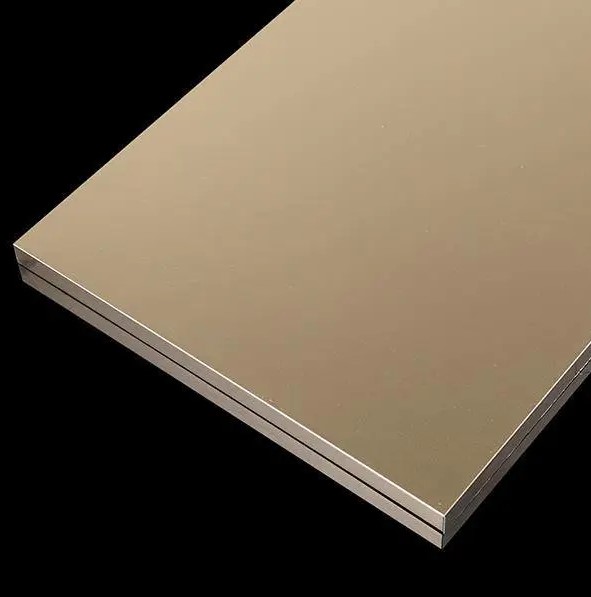

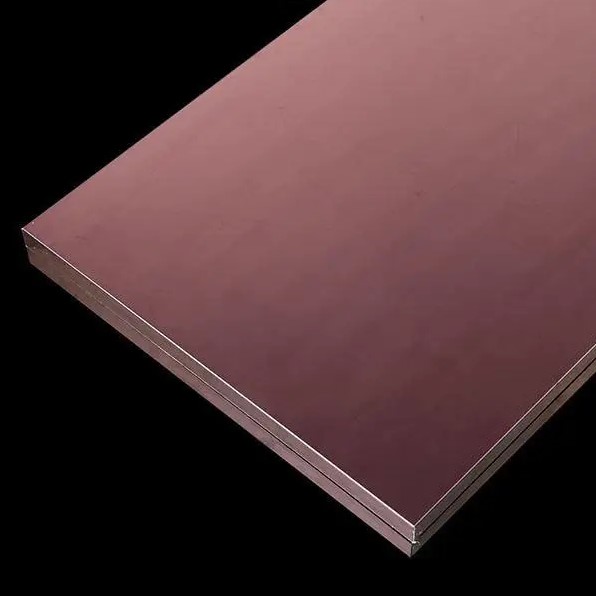

Bead blast finish, also known as bead blasting or sandblasting, is a surface treatment process that involves propelling fine particles at high velocity to clean, polish, or texture a material's surface. It uses compressed air to drive abrasive material against the surface, such as glass beads or metal shots, removing impurities, rust, paint, and other pollutants.

The Process Of Bead Blasting

The bead blasting process involves several key steps:

Surface Preparation: The surface to be treated must be carefully cleaned and prepped before bead blasting can begin. To guarantee effective blasting and the best results, any grease, oil, dirt, or rust should be removed.

Selection of Abrasive Material: The texture and polish of the treated surface are determined by the abrasive substance used. Different materials have varying degrees of hardness, size, and shape, which will influence the outcome. Glass beads are commonly used for general-purpose applications, while aluminum oxide or steel shots may be chosen for more aggressive surface treatments.

Blasting Equipment: Bead blasting is typically performed using specialized equipment, such as a sandblasting cabinet or a handheld blasting gun. These tools direct the abrasive material toward the surface with compressed air or mechanical force, creating the desired impact and texture.

Blasting Process: The bead blasting procedure begins after the equipment is set up. To guarantee uniform coverage and consistent results, the operator carefully controls the nozzle and pushes it around the surface. The blasting intensity, as well as the time and angle, may be modified to obtain the desired texture and look.

Surface Finishing: Following the bead blasting process, the surface may be subjected to further treatments to improve its look or to protect it against corrosion. To retain the texture and increase durability, a protective coating such as paint, powder coating, or transparent sealants can be used.

Applications Of Bead Blast Finish

Bead blast finish finds application in various industries, including automotive, aerospace, manufacturing, construction, and even art. Some common applications include:

Automotive: Bead blasting is used to prepare car bodies for painting, remove rust from exhaust systems, and restore old vehicles.

Aerospace: It aids in the cleaning of aviation components, the preparation of surfaces for bonding or painting, and the removal of corrosion from parts.

Manufacturing: Bead blast finish is employed for deburring, cleaning, and enhancing the surface texture of metal, plastic, and ceramic parts.

Construction: It can be used to prepare concrete surfaces for repairs, create decorative finishes, and clean architectural structures.

Art and Sculpture: Bead blasting is popular among artists for texturing, shaping, and finishing metal, glass, and stone sculptures.

Conclusion

This surface finishing technique is suitable for a wide range of purposes, and it works well on several materials.

Suppose you’re looking for the best bead blasted stainless steel sheet, look no further than XINGUANGYUAN. Contact us for more product details and request a quote today! Let’s help get your project to the next level!