Stainless steel is a flexible and corrosion-resistant material that is used in a variety of sectors, including construction, manufacturing, and others. Choosing the proper grade for your unique needs is an important issue when employing stainless steel. With numerous stainless steel grades available, it's essential to make an informed choice, particularly when it comes to stainless steel coils. In this article, we will guide you through the process of choosing the right stainless steel coil grade for your project.

Understand the Basics

Before delving into specific grades, it's crucial to have a fundamental understanding of stainless steel and its properties. Stainless steel is an iron alloy with at least 10.5% chromium, which creates a protective oxide coating on the surface to prevent rust and corrosion. The various grades differ in terms of their chemical composition, and this significantly affects their performance characteristics.

.jpg)

Identify Your Application

The first step in choosing the right stainless steel coil grade is to clearly define your application and its requirements. Consider factors such as temperature, corrosion resistance, strength, and appearance. Is the stainless steel coil being used in a maritime environment, a food processing facility, or a structural application? Each of these applications may necessitate a different grade of stainless steel.

Stainless Steel Grades

Each stainless steel grade has unique attributes and properties that make it suitable for different applications. Let's explore the grades mentioned earlier in more detail:

304 Stainless Steel: This is the workhorse of the stainless steel family. It's known for its versatility, excellent corrosion resistance, and relatively low cost. It's utilized in everything from kitchen appliances to structural components.

316 Stainless Steel: This grade offers superior corrosion resistance, making it ideal for marine environments, chemical processing, and medical equipment. Because of its increased nickel and molybdenum content, it is more resistant to chloride-based corrosion.

430 Stainless Steel: Known for its resistance to oxidation and heat, 430 stainless steel is often used in kitchen appliances, cutlery, and furnace components. Its durability and resistance to corrosion make steel a good option for these applications.

410 Stainless Steel: If you need high strength and hardness, 410 stainless steel is a top choice. It's frequently utilized in industrial equipment and machinery parts where wear resistance and strength are critical.

PVD Color Stainless Steel Coil For Interior Design

Corrosion Resistance

Corrosion resistance is one of the most critical factors in selecting a stainless steel grade. It determines how well the material will perform in harsh or corrosive environments. Some grades, like as 316 and 904L, are extremely resistant to corrosive substances such as acids, salts, and alkaline solutions. Consider the corrosion difficulties that your application will experience and select a stainless steel grade that can survive those circumstances.

Temperature Resistance

The capacity of stainless steel to endure high or low temperatures is dependent on its composition. Grades like as 309 and 310 are designed to preserve mechanical characteristics even at temperatures above 1000°C. Conversely, if cryogenic temperatures are a concern, grades like 304L or 316L are suitable options due to their lower carbon content, which improves low-temperature toughness.

.jpg)

NO.8 Mirror Stainless Steel Coil

Strength And Durability

The strength and durability of the stainless steel coil are essential factors to consider. Some applications, such as structural components or aerospace components, require high-strength stainless steel grades.

In contrast, if your application requires a high level of wear and tear, you may require a grade with good wear resistance.

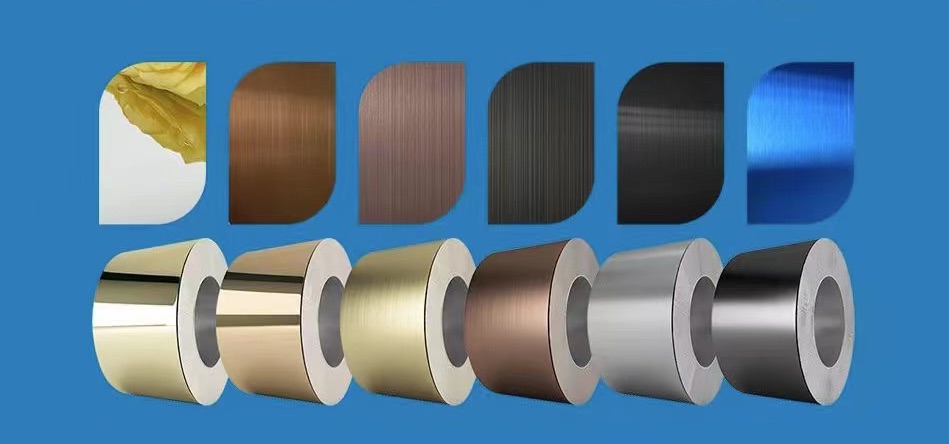

Aesthetics

The visual attractiveness of stainless steel is frequently a crucial element in architectural, interior design, and ornamental applications. The choice of finish, such as mirror, brushed, or matte, can greatly affect the appearance of the stainless steel coil.

Surface finish choices and treatments are available for numerous stainless steel grades, allowing you to obtain the desired aesthetic impact, whether it's a sleek, polished finish or a more rustic, brushed look.

Conclusion

Selecting the right stainless steel coil grade is crucial for the success of your project. If you are looking for a trusted stainless steel coil supplier, XINGUANGYUAN is your good choice. Please feel free to contact us for more detail about the products.