Stainless steel, renowned for its durability and corrosion resistance, is a versatile material used in countless applications. However, even this resilient alloy can develop rust under certain conditions. As a leading manufacturer of high-quality stainless steel products, Xinguangyuan understands the critical importance of maintaining the integrity and aesthetic appeal of stainless steel surfaces. In this comprehensive guide, we'll explore effective techniques for removing rust and preventing its formation, drawing from our extensive expertise in stainless steel surface processing.

Understanding Rust on Stainless Steel

Despite its name, "stainless" steel is not entirely immune to rust. Stainless steel owes its corrosion resistance to a minimum chromium content of 10.5%, which forms a protective passive layer on the surface. However, under specific circumstances, this material can still develop rust. Let's examine the primary factors that can lead to rust formation on stainless steel:

-

Iron Contamination: During manufacturing, fabrication, or installation processes, stainless steel can become contaminated with iron particles. These iron deposits can lead to rust spots on the surface.

-

Damage to the Passive Layer: The thin, passive chromium oxide layer on stainless steel's surface is key to its corrosion resistance. If this layer is compromised by scratches, dents, or chemical exposure, the underlying metal becomes vulnerable to rusting.

-

Chloride Exposure: Prolonged contact with chlorides, such as those found in seawater, deicing salts, or certain cleaning products, can cause pitting corrosion and subsequent rusting on stainless steel.

-

Improper Maintenance: Neglecting regular cleaning and maintenance can allow contaminants and corrosive substances to accumulate on stainless steel surfaces, eventually leading to rust formation.

-

Environmental Factors: High humidity, extreme temperatures, and exposure to certain industrial pollutants can accelerate the corrosion process in stainless steel.

It's important to note that different types of stainless steel exhibit varying levels of corrosion resistance. The four main categories are:

- Austenitic (300 series): Highly corrosion-resistant, non-magnetic

- Ferritic (400 series): Moderate corrosion resistance, magnetic

- Martensitic (400 series): Lower corrosion resistance, can be hardened

- Duplex: Combines properties of austenitic and ferritic, high strength and corrosion resistance

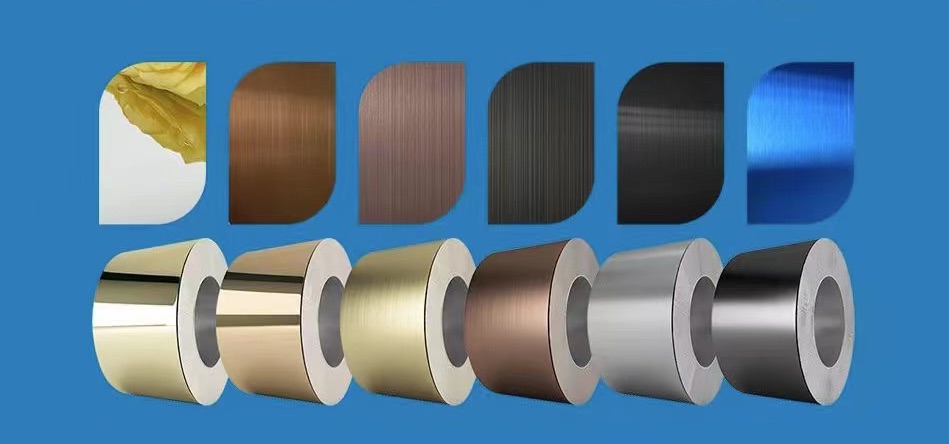

At Xinguangyuan, we specialize in working with various grades of stainless steel to meet diverse industry needs. Our expertise in surface processing techniques, including mirror polishing, frosting, drawbenching, glazing, and etching, allows us to offer tailored solutions for rust removal and prevention across different stainless steel types.

Effective Rust Removal Techniques

When rust appears on stainless steel, prompt action is crucial. Here are several proven methods for rust removal, ranging from DIY solutions to professional-grade treatments:

1. Baking Soda and Water Paste

For light rust stains, this simple yet effective method can work wonders:

- Mix baking soda and water to form a thick paste

- Apply the paste to the rusted area and let it sit for 10-15 minutes

- Gently scrub the area with a soft-bristled brush or non-abrasive scouring pad, following the grain of the stainless steel

- Rinse thoroughly with clean water and dry with a soft cloth

2. Vinegar and Salt Solution

The acidic properties of vinegar combined with the abrasive nature of salt can tackle more stubborn rust stains:

- Create a paste by mixing equal parts white vinegar and salt

- Apply the paste to the rusted area and allow it to sit for 15-20 minutes

- Scrub the area gently with a soft-bristled brush or non-abrasive pad, following the steel's grain

- Rinse thoroughly and dry the surface completely

3. Commercial Rust Removers

For severe rust cases, specially formulated commercial products can be highly effective:

- Select a rust remover designed specifically for use on stainless steel

- Apply the product according to the manufacturer's instructions

- Allow it to sit for the recommended duration

- Gently scrub the area, always following the grain of the stainless steel

- Rinse thoroughly and dry the surface

4. Xinguangyuan's Professional Rust Removal Service

For particularly challenging rust issues or large-scale applications, Xinguangyuan offers professional rust removal services. Our experienced technicians use advanced techniques and specialized equipment to safely and effectively remove rust while preserving the integrity of the stainless steel surface.

Preventing Rust on Stainless Steel

At Xinguangyuan, we firmly believe that prevention is the best approach to maintaining the beauty and longevity of stainless steel surfaces. Here are our expert recommendations for rust prevention:

-

Regular Cleaning: Establish a routine cleaning schedule using mild detergents and soft cloths or sponges. Avoid abrasive materials that can scratch the surface and compromise the passive layer.

-

Prompt Drying: After cleaning or exposure to moisture, thoroughly dry stainless steel surfaces to prevent water spots and potential rust formation.

-

Proper Handling: Exercise caution during fabrication, installation, and maintenance to avoid damaging the passive layer through scratches, dents, or chemical exposure.

-

Chloride Avoidance: Minimize exposure to chlorides by using chloride-free cleaning products and avoiding prolonged contact with seawater or deicing salts.

-

Environmental Control: Maintain a dry and well-ventilated environment for stainless steel surfaces, as high humidity and moisture can accelerate rust formation.

-

Protective Coatings: Consider applying protective coatings or sealants specifically designed for stainless steel to enhance its corrosion resistance in harsh environments.

-

Regular Inspections: Conduct periodic inspections of stainless steel surfaces to identify and address potential issues early on.

-

Proper Grade Selection: Choose the appropriate grade of stainless steel for your specific application and environment to ensure optimal corrosion resistance.

Case Study: Xinguangyuan's Rust Prevention Success

In a recent project for a major food processing facility, Xinguangyuan implemented a comprehensive rust prevention strategy for their stainless steel equipment. By combining our high-quality 316L grade stainless steel with a custom surface treatment and a tailored maintenance plan, we achieved a 95% reduction in rust-related issues over a two-year period. This resulted in significant cost savings for the client and improved overall equipment reliability.

Xinguangyuan: Your Trusted Partner for Stainless Steel Solutions

With over two decades of experience in stainless steel manufacturing and surface processing, Xinguangyuan is uniquely positioned to address all your stainless steel needs. Our comprehensive range of solutions caters to diverse industries, including kitchen appliances, medical devices, elevator decoration, architectural elements, and more.

Our commitment to quality is evident in every aspect of our work:

- State-of-the-art manufacturing facilities

- Rigorous quality control measures

- Continuous innovation in surface treatment technologies

- Expert team of metallurgists and engineers

- Customized solutions for unique client requirements

Whether you're seeking high-performance stainless steel components, expert rust removal services, or tailored rust prevention strategies, Xinguangyuan has the expertise and resources to deliver exceptional results.

Contact Xinguangyuan today to learn how we can help you maintain the beauty, functionality, and longevity of your stainless steel surfaces. Let us be your partner in harnessing the full potential of this remarkable material.