316 stainless steel is only slightly magnetic under certain conditions. This austenitic stainless steel grade contains iron, which is ferromagnetic, but the high chromium and nickel content gives it non-magnetic properties at room temperature.

What Makes Stainless Steel Magnetic or Non-Magnetic?

Stainless steel is an iron-based alloy known for its corrosion resistance and durability. However, the magnetic properties of stainless steel can vary depending on its composition and microstructure. In the case of 316 stainless steel, a common austenitic grade, the answer to whether it is magnetic or not is not a simple yes or no.

The magnetic behavior of stainless steel is primarily determined by its crystal structure and the presence of ferromagnetic elements like iron. Ferritic and martensitic stainless steels, which have a body-centered cubic (BCC) crystal structure, tend to be magnetic due to their higher iron content. On the other hand, austenitic stainless steels like 316 have a face-centered cubic (FCC) crystal structure with lower iron levels, making them non-magnetic or only slightly magnetic at room temperature.

Factors Influencing 316 Stainless Steel Magnetism

While 316 stainless steel is generally considered non-magnetic, several factors can influence its magnetic behavior:

-

Temperature: At very low temperatures (below -60°C/-76°F), the FCC structure of 316 can partially transform to a magnetic BCC structure, a phenomenon known as the martensitic transformation. This increases its magnetic permeability.

-

Cold Working: Severe cold working or cold rolling can induce strain in the microstructure, leading to a slight increase in magnetic properties. However, this effect is typically negligible for most applications.

-

Welding: The heat-affected zones near welds can undergo microstructural changes, potentially increasing local magnetic permeability. Proper welding techniques and post-weld heat treatments can minimize this effect.

-

Contaminants: The presence of ferromagnetic contaminants, such as iron particles or inclusions, can locally increase the magnetic response of 316 stainless steel. Proper manufacturing and handling practices help prevent such contamination.

Applications of Non-Magnetic 316 Stainless Steel

The non-magnetic properties of 316 stainless steel make it suitable for various applications where magnetic interference must be avoided, such as:

- Medical equipment and surgical instruments

- Cryogenic vessels and low-temperature applications

- Aerospace and aviation components

- Electrical enclosures and shielding

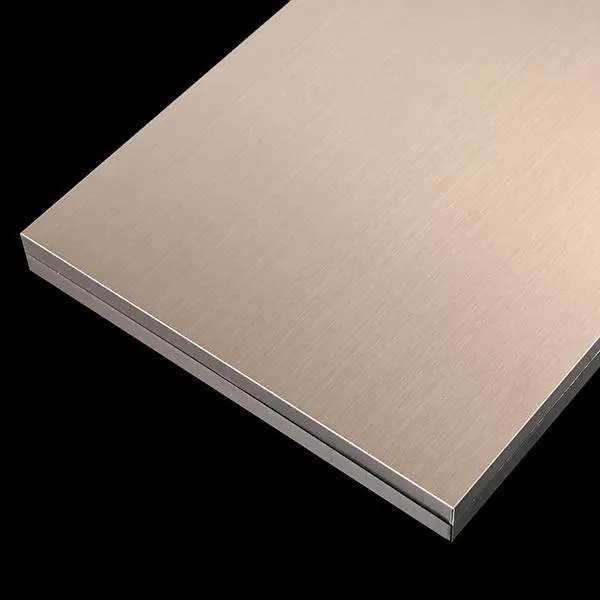

At Xinguangyuan, we specialize in providing high-quality 316 stainless steel products for a wide range of industries, including kitchen appliances, medical devices, elevator decoration, and more. Our expertise in surface processing techniques, such as polishing, brushing, and coloring, ensures that our customers receive products that meet their specific requirements, including non-magnetic properties when necessary.

Conclusion

In summary, while 316 stainless steel is generally considered non-magnetic at room temperature, its magnetic behavior can be influenced by factors such as temperature, cold working, welding, and contaminants. Understanding these factors is crucial for applications where magnetic permeability must be carefully controlled.

At Xinguangyuan, we are dedicated to providing our customers with accurate and reliable information, as well as high-quality products that meet their specific needs. If you have any further questions or would like to learn more about our stainless steel solutions, please don't hesitate to contact us.