No.8 mirror stainless steel sheets, often referred to as super mirror polished sheets, are celebrated for their exceptional gloss and reflective properties. These sheets find extensive use in various sectors, including architecture, design, and industrial applications. Selecting the right material is crucial, as it influences both the aesthetic appeal and functionality of the final product.

Understanding No.8 Mirror Finish

What is No.8 Mirror Finish?

The No.8 finish is distinguished by its non-directional, highly reflective surface, achieved through a meticulous polishing process. This finish is created using finer abrasives and buffing compounds, resulting in a flawless surface that effectively reflects light. Unlike other finishes, such as No.7, which may exhibit directional lines, the No.8 finish offers a uniform appearance that significantly enhances visual appeal.

Production Process

The manufacturing process for No.8 mirror stainless steel involves several key steps:

Base Material Selection: Typically made from 304 or 316L stainless steel grades, known for their corrosion resistance and durability.

Initial Polishing: The sheets undergo an initial polishing process using 2B or BA finishes.

Chemical Wet Polishing: This step utilizes a chemical solution to achieve a non-directional super mirror finish that is transparent and free of line marks.

Final Inspection: Rigorous quality checks ensure that the sheets meet industry standards for reflectivity and surface quality.

No.8 Mirror Stainlee Steel Sheets

Key Factors in Choosing No.8 Mirror Stainless Steel Sheets

When selecting the best No.8 mirror stainless steel sheets for your project, consider the following factors:

1. Material Grade

Choosing the right grade is essential for ensuring durability and performance:

304 Stainless Steel: This grade offers good corrosion resistance and is commonly used for indoor applications.

316L Stainless Steel: Known for its superior corrosion resistance, this grade is ideal for outdoor environments or areas exposed to harsh chemicals.

2. Thickness

The thickness of the stainless steel sheet can significantly impact its strength and suitability for various applications. Common thicknesses range from 0.3mm to 6mm:

Thinner sheets (0.3 - 1.0mm) are typically used for decorative applications.

Medium thickness sheets (1.5 - 3.0mm) are suitable for architectural elements.

Thicker sheets (4.0 - 6.0mm) are often employed in structural components.

3. Finish Quality

Ensure that the finish meets your aesthetic requirements:

Reflectivity: A higher level of reflectivity enhances visual appeal.

Blemish-Free Surface: A uniform surface without scratches or imperfections is crucial for decorative uses.

No.8 Mirror Stainless Steel Sheet Manufacturers

4. Environmental Resistance

For applications exposed to outdoor elements, select grades that offer enhanced resistance to environmental factors:

Corrosion Resistance: Essential for longevity in harsh conditions.

Weather Resistance: Important for maintaining appearance over time.

Applications of No.8 Mirror Stainless Steel Sheets

No.8 mirror stainless steel sheets are versatile and can be utilized across various sectors:

Architectural Applications

These sheets are commonly used in architectural designs:

Wall Panels: They create striking visual effects both indoors and outdoors.

Elevator Interiors: Enhancing aesthetics while providing durability against wear and tear.

Industrial Uses

In industrial settings, these sheets serve multiple purposes:

Food Preparation Areas: Their non-porous surface is easy to clean and hygienic.

Equipment Manufacturing: Often used in appliances due to their reflective properties and ease of maintenance.

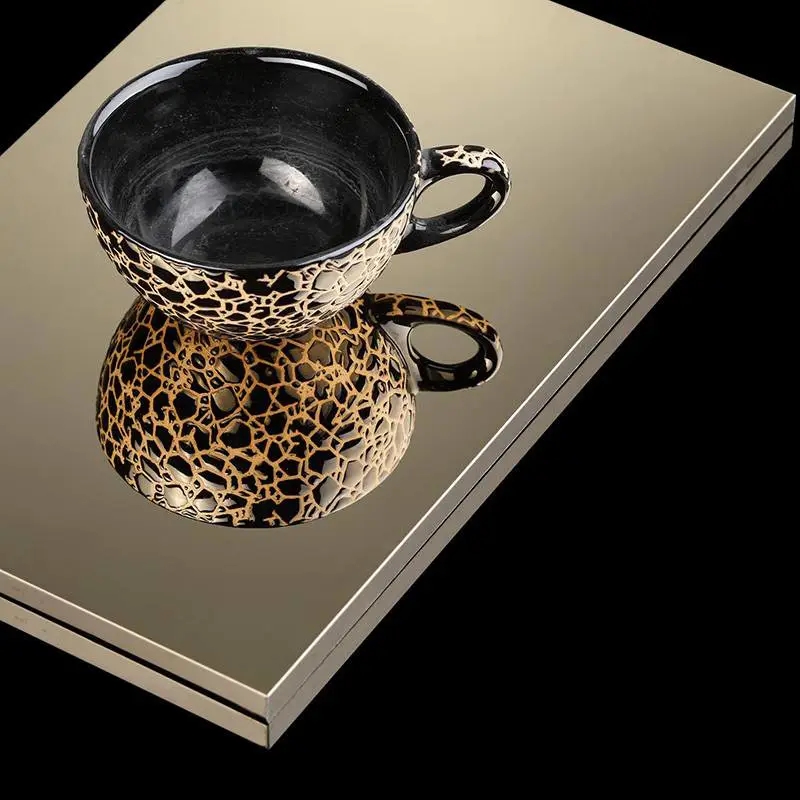

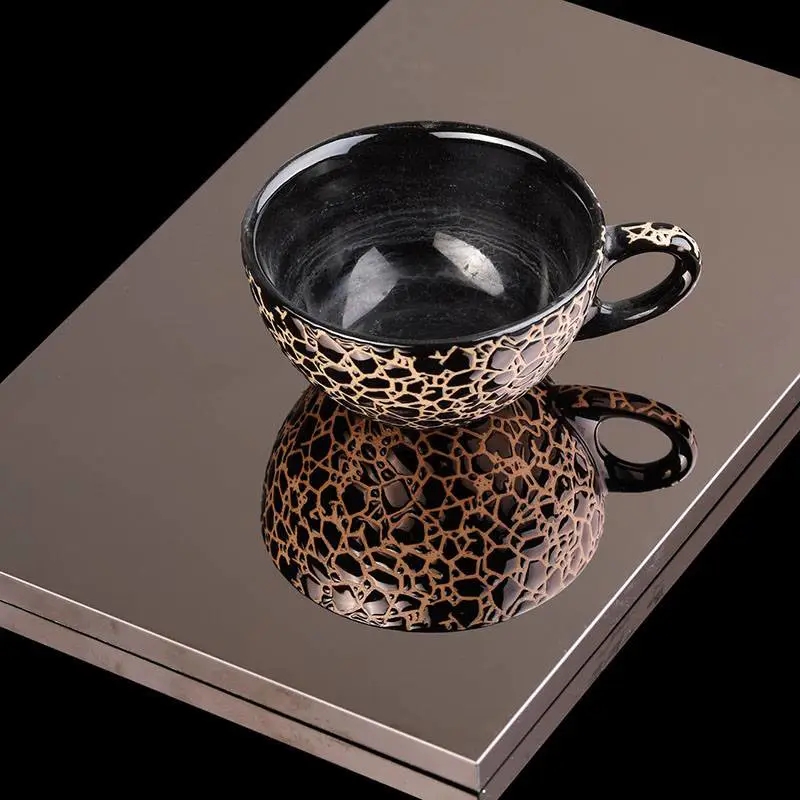

Decorative Elements

No.8 mirror stainless steel sheets also find use in decorative contexts:

Art Installations: Artists frequently utilize these sheets for their reflective qualities.

Furniture Design: They add a modern touch to various furniture pieces.

No.8 Mirror Stainless Steel Sheet Suppliers

Maintenance of No.8 Mirror Stainless Steel Sheets

To maintain the pristine appearance of No.8 mirror stainless steel sheets, follow these guidelines:

Cleaning Techniques

Regular Dusting: Use a soft cloth to remove dust particles regularly.

Gentle Cleaning Solutions: Opt for mild detergents or specialized stainless steel cleaners.

Avoid Abrasive Materials: Do not use scouring pads or harsh chemicals that can scratch the surface.

Preventive Measures

Anti-Fingerprint Coating: Consider applying a protective coating that reduces fingerprints and smudges.

Routine Inspections: Regularly check for signs of corrosion or damage, especially in outdoor applications.

Conclusion

Choosing the right No.8 mirror stainless steel sheet involves careful consideration of material grade, thickness, finish quality, and environmental resistance. With its wide range of applications—from architectural designs to industrial uses—No.8 mirror stainless steel offers both aesthetic appeal and functional durability.