Stainless steel is well-known for its durability, corrosion resistance, and elegant look, making it a preferred material in many sectors, including architecture, automobile, and electronics. To enhance both the aesthetic and functional properties of stainless steel, advanced surface treatments like Physical Vapor Deposition (PVD) color coating have gained prominence. In this article, we will delve into the intricacies of PVD color coating on stainless steel coils, exploring its process, benefits, and applications.

What Is PVD Color Coating?

PVD color coating is a specialized procedure that includes depositing tiny layers of materials onto the surface of stainless steel using a vacuum deposition method. The term "Physical Vapor Deposition" refers to the method where solid material is transformed into vapor and then condensed onto the substrate, creating a thin, durable coating.

The PVD process typically involves the following steps:

Preparation Of Substrate: The stainless steel coil is thoroughly cleaned and prepared to achieve a perfect and smooth surface for the future coating procedure.

Vacuum Chamber: Placed within a vacuum chamber, the prepared coil experiences a reduction in air pressure, creating an environment conducive to the PVD process.

Evaporation: The coating material, often metals or alloys, is heated until it vaporizes. This vaporized material then travels to the substrate.

Deposition: The vaporized substance condenses on the stainless steel coil's surface, forming a thin, adherent coating of the desired color or finish.

Cooling and Solidification: The coated stainless steel coil is cooled to harden the deposited material, creating a durable and beautiful surface.

PVD Color Stainless Steel Coil Manufacturers

Advantages Of PVD Color Coating on Stainless Steel Coils

Chemical And Corrosion Resistance

PVD color coating significantly enhances the chemical and corrosion resistance of stainless steel coils. The deposited thin coating serves as a barrier, shielding the steel surface from corrosive elements, harsh chemicals, and environmental conditions. This makes PVD-coated stainless steel suitable for applications in demanding environments, such as coastal areas or industrial settings.

Scratch And Wear Resistance

The PVD coating adds a robust layer to the stainless steel surface, increasing its resistance to scratches and wear. This is especially useful in situations where the material is subjected to frequent handling, minimizing the possibility of surface damage and preserving aesthetic appeal over time.

UV Stability

PVD color coatings exhibit excellent UV stability, ensuring that the vibrant colors and finishes remain intact even when exposed to sunlight. PVD-coated stainless steel coils are appropriate for external applications that need color preservation, such as architectural facades or exterior features.

PVD Color Stainless Steel Coil

Customization And Design Flexibility

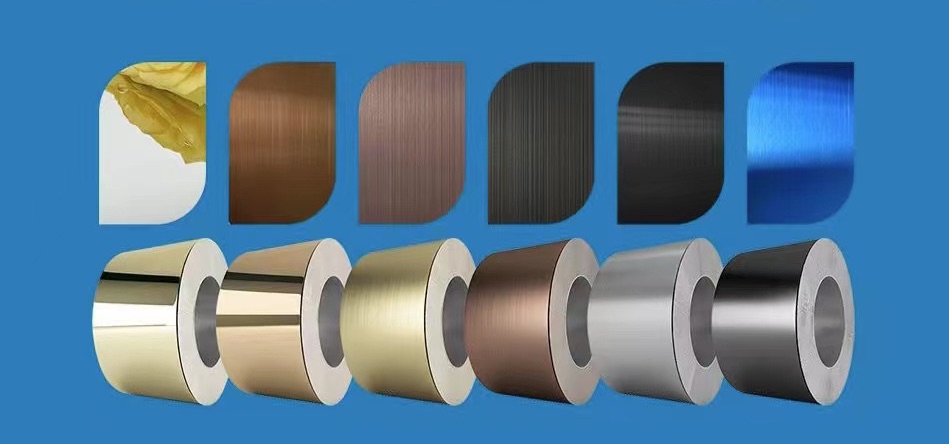

One of the primary benefits of PVD color coating is the ability to modify the look of stainless steel based on specific design specifications. Manufacturers and designers can achieve a wide spectrum of colors, patterns, and finishes, providing unparalleled design flexibility. PVD-coated stainless steel is a popular choice in the architectural and interior design sectors due to its flexibility to be customized.

Low Maintenance Requirements

PVD-coated stainless steel is known for its low maintenance requirements. The durable coating reduces the need for regular cleaning or polishing, lowering the total maintenance expenses associated with stainless steel items. This makes it an attractive choice for applications where ease of maintenance is a critical factor.

Improved Hardness And Adhesion

PVD coatings contribute to improved hardness and adhesion on the stainless steel surface. This results in a more robust and resilient material that can bear mechanical pressures while preserving its integrity under a variety of operating circumstances.

Pvd Color Stainless Steel Coils

Environmentally Friendly

PVD color coating is considered an environmentally friendly technology. The procedure uses no toxic solvents and produces little waste, which contributes to sustainable manufacturing processes. This aligns with the growing emphasis on eco-friendly solutions in today's industries.

Uniform And Consistent Coating

PVD technology ensures a uniform and consistent coating on the entire stainless steel surface. This homogeneity improves the overall visual appeal and quality of the coated product by reducing discrepancies seen with previous coating processes.

Conclusion

In conclusion, PVD color coating on stainless steel coils represents a significant advancement in surface treatment technology. It combines aesthetic appeal and durability, providing a diverse option for sectors looking for visually appealing and long-lasting stainless steel goods. As a leading stainless steel supplier, XINGUANGYUAN offers a variety of stainless steel including stainless steel sheets and stainless steel coils to fit applications. Visit our site today to learn more about what we offer.