Physical Vapor Deposition (PVD) has revolutionized the way stainless steel is perceived and utilized in interior design. By applying a thin film of metal or metal compound to the surface of stainless steel, PVD enhances both its aesthetic appeal and functional properties. This article explores the various aspects of PVD color stainless steel coils, focusing on their role in enhancing aesthetics in interior design.

What is PVD Coating?

Understanding the PVD Process

PVD is a vacuum coating technique that involves the vaporization of a solid material, which then condenses on the substrate—in this case, stainless steel. The process typically occurs in a controlled environment at temperatures ranging from 150 to 500 degrees Celsius. Key steps include:

Surface Preparation: Stainless steel sheets are cleaned to remove contaminants, ensuring optimal adhesion.

Loading: The sheets are placed in a vacuum chamber where the coating material is evaporated.

Deposition: Metal vapors travel through the vacuum and deposit uniformly on the stainless steel surface.

This method allows for precise control over thickness and color, resulting in a durable and visually appealing finish.

Benefits of PVD Coating

PVD coatings offer numerous advantages:

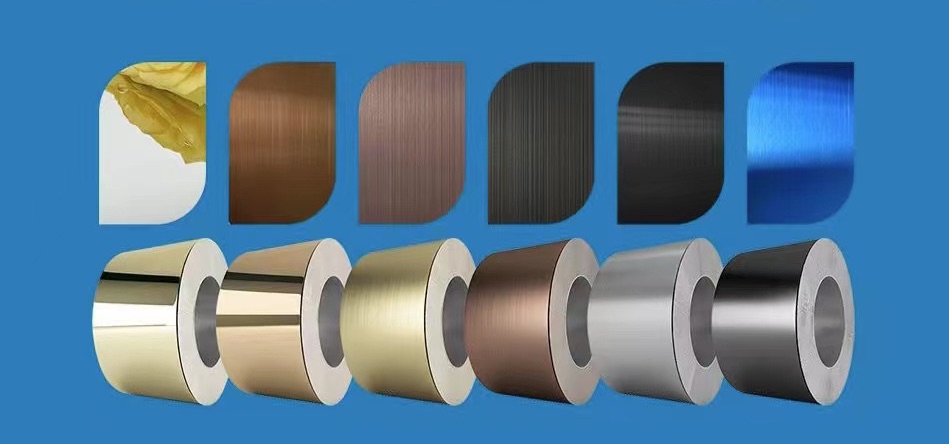

Aesthetic Versatility: A wide range of colors and finishes can be achieved, including gold, rose gold, black, and bronze.

Durability: The coating enhances wear resistance, making it suitable for high-traffic areas.

Corrosion Resistance: The additional layer protects against environmental factors such as moisture and chemicals.

Eco-Friendly: The PVD process is low-temperature and does not involve harmful chemicals.

Pvd Color Stainless Steel Coil For Interior Design

Applications of PVD Color Stainless Steel Coils in Interior Design

Architectural Elements

PVD color stainless steel coils are increasingly used in architectural applications due to their striking appearance and durability. Common uses include:

Facades: Buildings can achieve modern aesthetics with colorful cladding that also offers protection against the elements.

Railings and Balustrades: These components benefit from both visual appeal and enhanced safety features due to their strength.

Furniture Design

The use of PVD-coated stainless steel in furniture design allows for innovative creations that combine functionality with style. Examples include:

Tables and Chairs: Durable finishes resist scratches and maintain their vibrant appearance over time.

Cabinet Hardware: Handles and knobs can be customized to match overall design themes.

Decorative Features

Incorporating PVD color stainless steel into decorative elements can create focal points within a space. Applications include:

Wall Art: Unique installations can be created using various colors and textures.

Lighting Fixtures: The reflective qualities enhance light distribution while adding a modern touch.

Pvd Color Stainless Steel Coil Manufacturers

Design Considerations

Color Selection

Choosing the right color is critical for achieving the desired aesthetic. Factors to consider include:

Theme Compatibility: Colors should align with the overall design theme of the space.

Lighting Conditions: Different lighting can affect how colors appear; testing samples under various conditions is advisable.

Finish Types

Different finishes can dramatically alter the look of PVD-coated stainless steel:

Mirror Finish: Offers high reflectivity, ideal for contemporary designs.

Brushed Finish: Provides a softer appearance, suitable for more traditional settings.

Pvd Color Stainless Steel Coil For Decoration

Maintenance of PVD Color Stainless Steel

Cleaning Recommendations

Maintaining the appearance of PVD-coated surfaces requires specific care:

Use mild detergents with soft cloths to avoid scratching.

Avoid abrasive cleaners that could damage the coating.

Long-Term Care

Regular inspections for signs of wear or damage can help maintain the integrity of the coating. Promptly addressing any issues will ensure longevity.

Conclusion

PVD color stainless steel coils represent a significant advancement in material technology, providing both aesthetic appeal and functional benefits for interior design applications. Their versatility makes them an attractive choice for architects and designers seeking innovative solutions that elevate spaces while ensuring durability and ease of maintenance. As trends continue to evolve, PVD-coated materials will likely play an increasingly prominent role in shaping modern interiors.