Physical Vapor Deposition (PVD) technology has revolutionized the way we perceive and utilize stainless steel. PVD color stainless steel coils are a testament to this advancement, offering a blend of aesthetic appeal and enhanced functional properties. This article delves into the features and benefits of PVD color stainless steel coils, highlighting their applications and advantages.

Understanding PVD Coating

PVD, or Physical Vapor Deposition, is a sophisticated coating process that involves vaporizing solid materials, such as metals, to form a thin, highly adhered coating on a substrate. This process is carried out in a vacuum chamber, ensuring a clean and controlled environment that enhances the quality of the coating.

Key Characteristics of PVD Coating

Durability: PVD coatings are known for their exceptional hardness and wear resistance, making them ideal for applications that demand longevity.

Corrosion Resistance: The coating provides excellent protection against corrosion and oxidation, significantly extending the lifespan of the stainless steel.

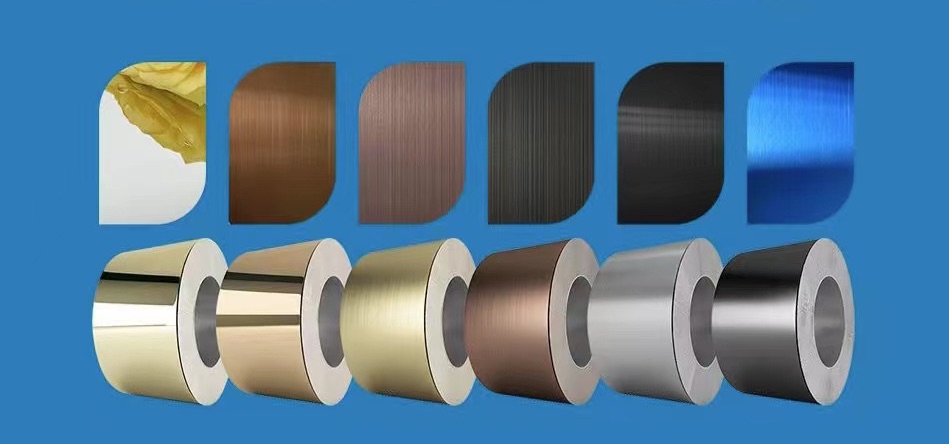

Aesthetic Versatility: PVD technology allows for a wide range of vibrant colors, from gold and champagne to black and green, offering limitless design possibilities.

Environmental Friendliness: Unlike traditional coating methods, PVD does not produce harmful by-products, making it a more sustainable option.

Pvd Color Stainless Steel Coil

Features of PVD Color Stainless Steel Coils

PVD color stainless steel coils are renowned for their unique features that set them apart from conventional stainless steel products.

Vibrant Color Options

One of the standout features of PVD-coated stainless steel is the array of colors available. By manipulating the gases used during the deposition process, manufacturers can achieve a spectrum of colors, including gold, champagne, black, and more. This makes PVD color stainless steel coils an attractive choice for decorative applications.

Enhanced Surface Properties

The PVD process not only adds color but also enhances the surface properties of stainless steel. The coating increases the material's hardness, making it resistant to scratches and wear. This is particularly beneficial for applications in high-traffic areas or environments where the material is subject to physical stress.

Thickness and Adhesion

PVD coatings are typically very thin, ranging from 0.25 to 10 micrometers, depending on the application. Despite their thinness, these coatings are highly durable and adhere well to the substrate, ensuring long-lasting performance.

Pvd Color Stainless Steel Coil Manufacturers

Benefits of Using PVD Color Stainless Steel Coils

The use of PVD color stainless steel coils offers numerous benefits across various industries.

Architectural and Interior Design

In architecture and interior design, PVD color stainless steel coils are used for cladding, wall panels, and decorative elements. Their vibrant colors and durability make them ideal for creating visually appealing and long-lasting designs.

Consumer Electronics

The electronics industry benefits from the use of PVD-coated stainless steel in products like smartphones, laptops, and other gadgets. The coating enhances the aesthetic appeal of these devices while providing protection against wear and corrosion.

Medical Equipment

PVD color stainless steel coils are also utilized in the medical field for equipment that requires high levels of cleanliness and durability. The coating's resistance to corrosion and ease of cleaning make it suitable for medical environments.

Pvd Color Stainless Steel Coil

Challenges and Considerations

While PVD color stainless steel coils offer numerous advantages, there are some challenges and considerations to keep in mind.

Cost and Complexity

The PVD coating process is more complex and expensive compared to traditional methods. This can increase the overall cost of the final product.

Color Consistency

Maintaining color consistency across different batches can be challenging due to variations in furnace conditions and other parameters. However, with meticulous control, a high level of color match can be achieved.

Conclusion

PVD color stainless steel coils represent a significant advancement in material science, offering a combination of beauty and functionality. Their durability, corrosion resistance, and aesthetic versatility make them a preferred choice in various industries, from architecture to electronics. Despite the challenges associated with the PVD process, the benefits of these innovative coatings make them a valuable addition to any design or application. As technology continues to evolve, the possibilities for PVD color stainless steel coils are virtually endless, promising even more exciting developments in the future.