When it comes to stainless steel finishes, the No. 4 finish is one of the most popular and widely used in a variety of industries. Whether for architectural design, kitchen appliances, or industrial applications, the stainless No. 4 finish offers a combination of aesthetic appeal and practical functionality. In this article, we’ll dive deep into the features, benefits, and common uses of the stainless No. 4 finish, as well as why it is a preferred choice in various sectors.

What is Stainless No. 4 Finish?

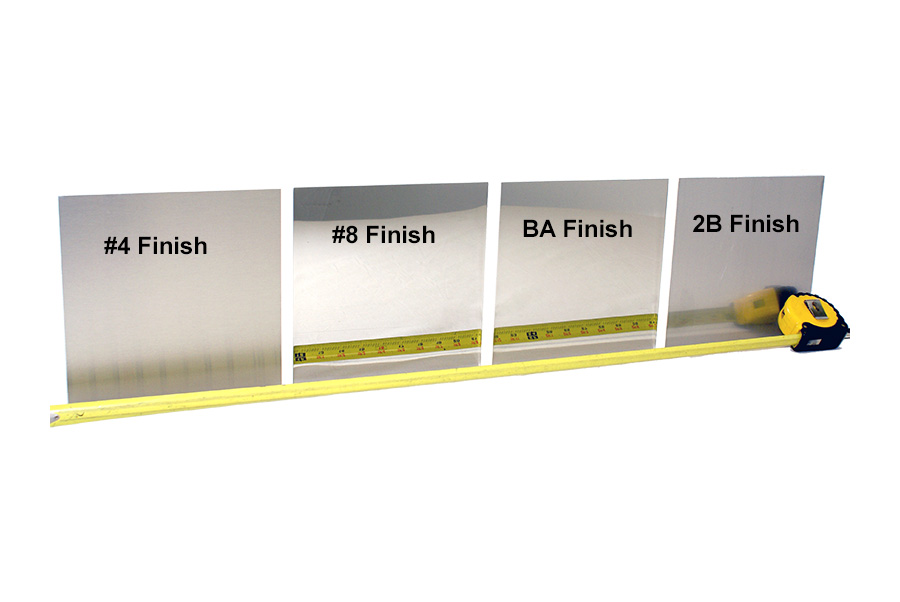

The No. 4 finish is a brushed, polished finish that has a smooth, non-reflective appearance with fine parallel polishing lines. Achieved by finishing stainless steel with abrasive belts or brushes, this finish is typically the result of a 150 to 180-grit process. The result is a satin-like surface that is commonly referred to as a "brushed finish."

Stainless steel with a No. 4 finish is most frequently used when both aesthetic and functional properties are required. It provides a sleek look while also being durable and resistant to corrosion.

Key Features of Stainless No. 4 Finish

-

Matte Brushed Appearance

The most defining characteristic of a No. 4 finish is its brushed appearance. It is not reflective like a mirror finish, making it ideal for environments where a subdued, modern look is desired. -

Scratch Resistance

While no surface is completely scratch-proof, the No. 4 finish is particularly good at hiding minor scratches and blemishes due to its textured, brushed surface. This makes it an ideal choice for high-traffic areas or surfaces that are frequently touched. -

Corrosion Resistance

Just like other stainless steel finishes, the No. 4 finish offers excellent corrosion resistance. This makes it suitable for both indoor and outdoor use, especially in environments where moisture or humidity is present. -

Ease of Maintenance

The satin-like surface of No. 4 finish stainless steel is easy to clean and maintain. It is highly resistant to smudges and fingerprints compared to more polished finishes, reducing the frequency of cleaning. -

Versatility

The No. 4 finish is incredibly versatile and is used across a wide range of industries and applications. From kitchen appliances and cabinetry to elevator panels and building facades, this finish is highly adaptable to various design aesthetics and functional needs.

Applications of Stainless No. 4 Finish

1. Architecture and Construction

The stainless No. 4 finish is widely used in the construction industry, particularly for interior wall panels, elevator doors, and architectural cladding. Its matte, brushed appearance gives buildings a modern, sleek look, while its durability ensures long-lasting performance, even in challenging environments.

2. Kitchen and Home Appliances

Kitchen appliances, countertops, and backsplashes are some of the most common applications for the No. 4 finish. It is often seen in refrigerators, dishwashers, ovens, and range hoods due to its resistance to fingerprints and scratches. The finish offers a clean, professional look that complements the design of most kitchens.

3. Food and Beverage Processing

Stainless steel with a No. 4 finish is commonly used in food and beverage processing due to its ease of cleaning and its resistance to corrosion and bacterial growth. From processing equipment to food preparation surfaces, this finish ensures cleanliness and hygiene, meeting industry standards.

4. Automotive Industry

The automotive industry frequently uses No. 4 finish stainless steel for both exterior and interior components. The finish provides the durability needed to withstand exposure to the elements while offering a visually appealing surface for trims, handles, and decorative elements.

5. Medical Equipment

The No. 4 finish is ideal for medical equipment and surgical instruments due to its non-porous, easy-to-clean surface. Stainless steel with this finish can be sanitized easily, making it a top choice for hospitals, clinics, and laboratories.

Benefits of Using Stainless No. 4 Finish

1. Aesthetically Pleasing

The smooth, brushed appearance of the No. 4 finish offers a contemporary and attractive look. It is the perfect balance between shiny and matte, making it a preferred choice for products that need to look professional and modern without being too flashy.

2. Durable and Long-Lasting

The combination of stainless steel’s inherent strength and the additional benefits of the brushed finish make No. 4 finish stainless steel incredibly durable. It holds up well against everyday wear and tear, providing a long-lasting solution for both functional and decorative applications.

3. Cost-Effective

Compared to higher-grade polished finishes, the No. 4 finish offers a cost-effective solution that doesn’t compromise on quality or appearance. This makes it an excellent choice for projects with tight budgets that still require a polished and professional finish.

4. Corrosion Resistance

Whether used indoors or outdoors, the corrosion resistance of stainless No. 4 finish ensures that it performs well in environments with exposure to moisture, chemicals, or other corrosive elements. This is particularly important for applications like kitchen equipment or exterior architectural elements.

5. Easy to Clean and Maintain

Due to its brushed finish, stainless steel with a No. 4 finish does not show fingerprints, water spots, or smudges as easily as more reflective finishes. This reduces the frequency of cleaning and maintenance, making it a practical choice for both home and industrial applications.

How to Choose the Right Supplier for Stainless No. 4 Finish

Selecting a reliable supplier for stainless No. 4 finish products is crucial to ensuring the success of your project. Here are a few factors to consider when choosing the right supplier:

- Quality Control: Ensure the supplier follows strict quality control processes to deliver consistently high-quality products.

- Customization Options: Look for suppliers that offer a range of stainless steel grades, thicknesses, and finishes to suit your specific requirements.

- Certifications: Verify that the supplier holds necessary certifications, such as ISO 9001, to ensure the products meet industry standards.

- Lead Times: Reliable suppliers will offer fast turnaround times to ensure your project stays on schedule.

- Customer Support: Choose a supplier that provides technical support and advice to help you choose the right materials for your specific needs.

Conclusion

The stainless No. 4 finish is a versatile and popular choice in a wide range of industries, thanks to its unique combination of aesthetic appeal, durability, and ease of maintenance. Whether used in architectural projects, kitchen appliances, or industrial equipment, the No. 4 finish offers a perfect balance between form and function.

If you’re looking for a durable, cost-effective, and visually appealing stainless steel solution, the No. 4 finish is an excellent option to consider. By choosing a trusted supplier, you can ensure that your No. 4 finish stainless steel products meet the highest standards of quality and performance.