High-performance stainless steel coil tubing has emerged as a critical component in various industries, including oil and gas, chemical processing, and aerospace. This innovative product combines durability and versatility, making it an ideal choice for applications that require reliable performance under extreme conditions. This article explores the characteristics, advantages, applications, and future trends of stainless steel coil tubing.

Understanding Stainless Steel Coil Tubing

What is Stainless Steel Coil Tubing?

Stainless steel coil tubing is a long, continuous tube that is wound on reels or spools. It is manufactured from high-quality stainless steel alloys, primarily 304 and 316 grades, known for their excellent corrosion resistance and mechanical properties. The seamless design of coil tubing eliminates welds or joints that can be potential weak points in traditional tubing systems.

Key Characteristics

-

Seamless Construction: Reduces the risk of leaks and improves overall system integrity.

-

Corrosion Resistance: High resistance to oxidation and corrosion makes it suitable for harsh environments.

-

Versatile Sizes: Available in various diameters and wall thicknesses to meet diverse application needs.

-

High Strength: Capable of withstanding high pressures and temperatures without deformation.

.jpg)

Advantages of High-Performance Stainless Steel Coil Tubing

Durability

Stainless steel coil tubing is designed to withstand extreme conditions, including high pressures and temperatures. Its robust construction ensures longevity, reducing the need for frequent replacements.

Cost Efficiency

Using long lengths of seamless tubing minimizes the number of joints required in a system. This not only reduces installation time but also lowers labor costs significantly. The potential for leaks is minimized, leading to lower maintenance costs over time.

Reduced Scrap and Waste

The ability to cut coil tubing to exact lengths on-site minimizes waste material. This efficiency contributes to sustainability efforts within industries by reducing the amount of scrap generated during installation.

Improved Safety

With fewer joints and connections, there are fewer potential leak points in a system. This enhances safety by reducing the likelihood of hazardous material leaks. Additionally, each length of tubing undergoes rigorous pressure testing before use, ensuring reliability.

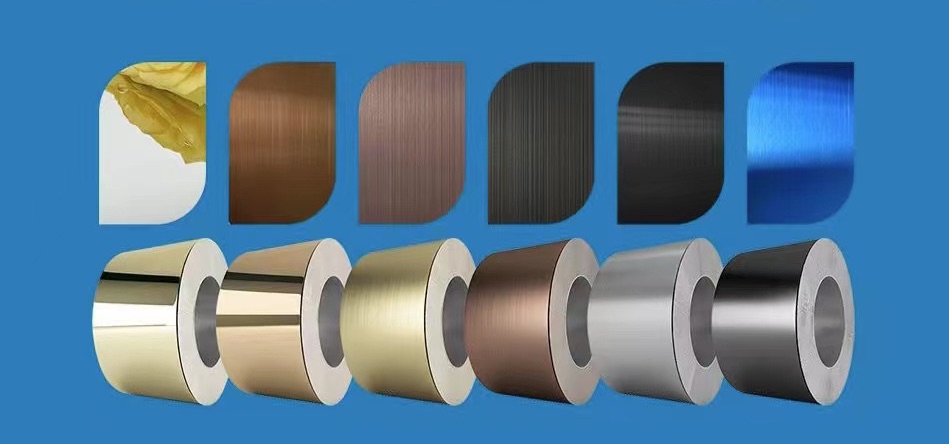

Stainless Steel Coil Suppliers

Applications of Stainless Steel Coil Tubing

Oil and Gas Industry

Stainless steel coil tubing is extensively used in the oil and gas sector for applications such as:

-

Hydraulic fracturing: Used for transporting fluids under high pressure.

-

Gas transfer: Ideal for transferring natural gas due to its strength and resistance to corrosion.

Chemical Processing

In chemical plants, stainless steel coil tubing is employed for:

-

Chemical injection lines: Transporting corrosive chemicals safely.

-

Heat exchangers: Efficiently transferring heat between fluids without degradation.

Aerospace and Defense

The aerospace industry utilizes stainless steel coil tubing in:

-

Fuel lines: Providing safe and reliable fuel transfer.

-

Hydraulic systems: Ensuring efficient operation under high-pressure conditions.

Medical Applications

High-purity stainless steel coil tubing is critical in medical settings for:

-

Fluid delivery systems: Ensuring contamination-free transport of fluids.

-

Instrumentation: Used in devices that require precise measurements.

.jpg)

Stainless Steel Coil Suppliers

Manufacturing Process

The manufacturing of stainless steel coil tubing involves several key steps:

-

Material Selection: High-quality stainless steel alloys are chosen based on application requirements.

-

Forming: The metal is formed into a tubular shape using advanced machinery.

-

Seamless Production: The seamless process eliminates welds, enhancing strength and reliability.

-

Testing: Each batch undergoes rigorous testing for pressure tolerance and material integrity.

Future Trends in Stainless Steel Coil Tubing

Innovations in Material Science

Research into new alloys with enhanced properties promises to improve the performance of stainless steel coil tubing further. Innovations may lead to even greater resistance to corrosion, higher strength-to-weight ratios, and improved thermal conductivity.

Sustainability Efforts

As industries move towards more sustainable practices, the demand for materials that minimize waste will grow. The efficiency of stainless steel coil tubing aligns well with these goals by reducing scrap during installation.

Increased Automation

The manufacturing process is increasingly becoming automated, leading to higher precision in production and reduced costs. Automation also allows for better quality control throughout the manufacturing process.

Conclusion

High-performance stainless steel coil tubing represents a significant advancement in materials engineering, providing unmatched durability and versatility across multiple industries. Its seamless construction offers numerous advantages, including cost savings, reduced waste, improved safety, and enhanced performance under extreme conditions. As technology continues to evolve, the future of stainless steel coil tubing looks promising with innovations that will further enhance its capabilities.

By understanding the benefits and applications of this remarkable product, industries can make informed decisions about their material choices, leading to improved efficiency and safety in their operations.