Stainless steel has long been celebrated for its durability and resistance to corrosion, making it a popular choice in various industries. However, the aesthetic potential of stainless steel is often overlooked. This guide explores the methods of color coating stainless steel, enhancing its visual appeal while maintaining its intrinsic properties.

The Appeal of Colored Stainless Steel

Aesthetic Versatility

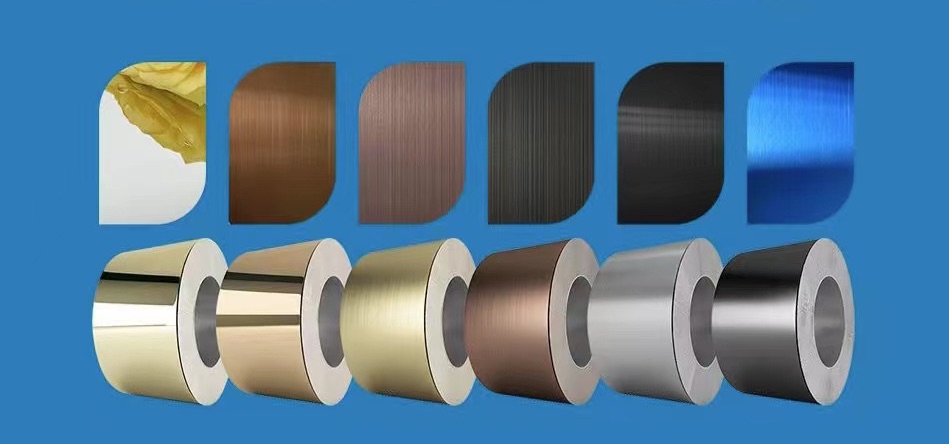

Colored stainless steel offers a wide range of colors, including black, gold, blue, brass, bronze, green, brown, and dark grey. This spectrum allows designers and architects to incorporate stainless steel into diverse applications, from modern interior designs to striking architectural facades. The ability to customize colors enhances the material's versatility in both commercial and residential projects.

Functional Benefits

Beyond aesthetics, colored stainless steel serves practical purposes. The color coating helps conceal fingerprints and smudges, making it easier to maintain a clean appearance. Additionally, darker hues can provide better coverage for scratches compared to lighter colors, which is particularly beneficial in high-traffic areas.

Methods of Coloring Stainless Steel

Physical Vapor Deposition (PVD)

PVD is a cutting-edge technology that significantly enhances the aesthetic and functional properties of stainless steel. The process involves placing stainless steel sheets in a vacuum chamber where a high-purity solid coating material—typically titanium or zirconium—is vaporized and deposited onto the surface. This method results in a thin yet durable layer that provides excellent scratch resistance and maintains color consistency across batches.

Advantages of PVD Coating

-

Durability: PVD coatings increase hardness and wear resistance.

-

Corrosion Resistance: Maintains the inherent corrosion resistance of stainless steel.

-

Eco-Friendly: The PVD process produces minimal waste and harmful by-products.

Electrochemical Coloring

Electrochemical coloring involves immersing stainless steel in an electrolyte solution while applying an electric current. This process modifies the surface layer of the metal, resulting in vibrant colors without compromising its structural integrity. This method is particularly effective for achieving consistent coloration across large surfaces.

Powder Coating

Powder coating is another popular method for coloring stainless steel. In this process, a dry powder is applied electrostatically to the metal surface and then cured under heat. This creates a hard finish that is tougher than conventional paint. Powder coating is available in various colors and textures, allowing for creative freedom in design.

Benefits of Powder Coating

-

Durability: Resistant to chipping, scratching, fading, and wearing.

-

Environmentally Friendly: Contains no solvents and produces minimal waste.

-

Variety: Offers a wide range of colors and finishes.

Stainless Steel Coil Wholesale

Preparing Stainless Steel for Color Coating

Surface Preparation

Proper surface preparation is crucial for ensuring optimal adhesion of color coatings. The steps involved typically include:

-

Cleaning: Remove any grease, dirt, or contaminants using solvent cleaners.

-

Abrasive Blasting: Create a profile on the surface to enhance mechanical bonding.

-

Passivation: Treat the surface with acids to remove oxides and improve corrosion resistance.

Choosing the Right Primer

For painting applications, selecting an appropriate primer is essential. Epoxy primers are recommended for their strong adhesion properties on stainless steel surfaces. It is vital to ensure that the primer is compatible with the chosen topcoat to avoid issues with adhesion and durability.

Maintenance of Colored Stainless Steel

Cleaning Techniques

Maintaining colored stainless steel requires specific cleaning techniques to preserve its appearance:

-

Use mild detergents or specialized cleaners designed for stainless steel.

-

Avoid abrasive materials that can scratch the surface.

-

Regularly wipe down surfaces to prevent buildup of dirt or contaminants.

Protection from Environmental Factors

While colored stainless steel is durable, exposure to harsh chemicals or extreme weather conditions can affect its appearance over time. It is advisable to use protective coatings if the material will be subjected to such environments.

Stainless Steel Coil Suppliers

Applications of Colored Stainless Steel

Architectural Design

Colored stainless steel has become increasingly popular in architectural applications due to its aesthetic appeal and durability. From building facades to interior accents, it offers designers flexibility in creating visually striking environments.

Consumer Products

In consumer goods, colored stainless steel is used in kitchen appliances, cookware, and furniture. Its ability to resist fingerprints makes it particularly suitable for high-use items where cleanliness is paramount.

Industrial Uses

Industries such as automotive and aerospace utilize colored stainless steel for both functional and aesthetic purposes. The enhanced durability provided by coatings ensures that components can withstand harsh operating conditions while maintaining an attractive appearance.

Conclusion

Colored stainless steel represents an exciting intersection of aesthetics and functionality. With various methods available for achieving vibrant colors without compromising durability or corrosion resistance, this material opens up new possibilities for design across multiple sectors. By understanding the processes involved in coloring stainless steel and implementing proper maintenance techniques, designers can unlock its full aesthetic potential while ensuring longevity in their applications.