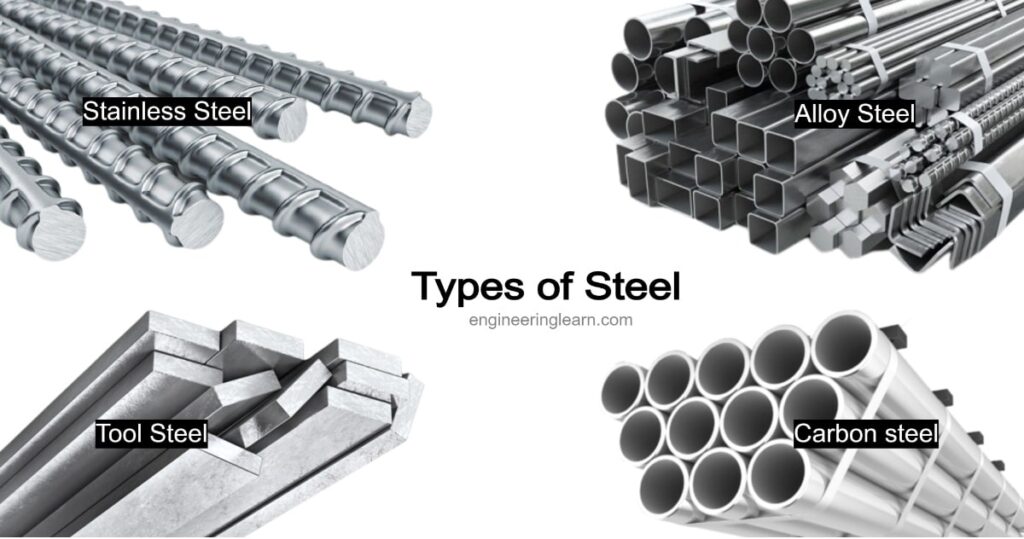

In the realm of industrial materials, the choice between stainless steel and carbon steel is a critical decision that can significantly impact the performance, durability, cost-effectiveness, and aesthetic appeal of your applications. These two steel types possess distinct characteristics that make them suitable for different scenarios, catering to diverse industry requirements. This comprehensive article delves into the key differences between stainless steel and carbon steel, empowering you to make an informed decision tailored to your specific needs.

Corrosion Resistance: The Stainless Steel Advantage

One of the most significant advantages of stainless steel over carbon steel is its superior corrosion resistance. Stainless steel contains chromium, typically between 10-20%, which forms an invisible passive layer that protects the metal from corrosion, rusting, and environmental degradation. This passive layer self-repairs when scratched or damaged, ensuring long-lasting protection in harsh environments, such as coastal regions, chemical processing facilities, or outdoor applications.

In contrast, carbon steel is more susceptible to corrosion and rusting, especially in moist, chemically aggressive, or outdoor conditions. While coatings like galvanization can provide temporary protection, they are prone to wear and require regular maintenance, increasing the overall cost of ownership and potentially compromising the structural integrity over time.

Strength and Durability: Carbon Steel's Inherent Advantage

While stainless steel is renowned for its corrosion resistance, carbon steel often outperforms it in terms of sheer strength and durability. Carbon steel has a higher tensile strength and hardness, making it a preferred choice for applications that require structural integrity, resistance to wear and tear, and the ability to withstand heavy loads and impacts. This makes carbon steel an ideal material for construction projects, machinery components, heavy equipment, and cutting tools.

However, it's important to note that stainless steel can be strengthened through various heat treatment processes, such as cold working or precipitation hardening, to achieve comparable or even superior strength levels to carbon steel. For example, Xinguangyuan's mirror 8K stainless steel coil offers an unparalleled level of reflectivity and brilliance while maintaining exceptional strength and durability, making it an ideal choice for decorative applications where a mirror-like finish is desired.

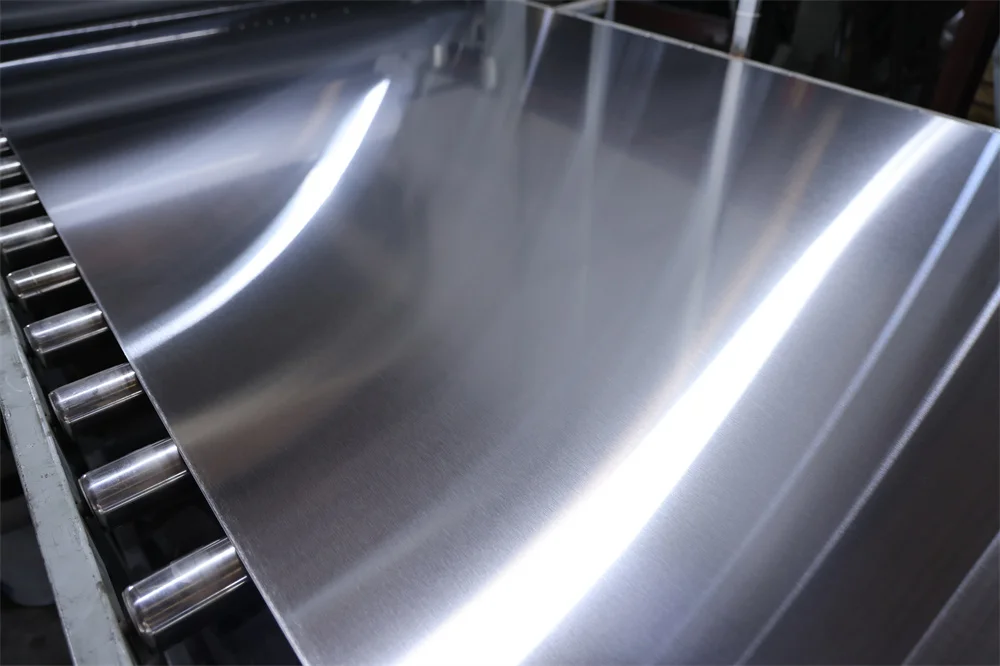

Appearance and Aesthetics: Stainless Steel's Sleek Appeal

Stainless steel's sleek and modern appearance makes it a popular choice for applications where aesthetics are a priority. Its natural luster and resistance to discoloration allow it to maintain a clean and attractive look over time, even in harsh environments. This makes stainless steel an ideal choice for architectural and decorative elements, consumer products, and applications where visual appeal is essential, such as kitchen appliances, medical devices, elevator decoration, doors, hotel decoration, and hardware.

Carbon steel, on the other hand, is more prone to discoloration and requires regular maintenance to maintain its appearance. However, carbon steel can be painted or coated to achieve a desired aesthetic, albeit at the cost of additional maintenance and potential corrosion risks if the coating is compromised.

Cost and Availability: Carbon Steel's Economic Advantage

One of the primary advantages of carbon steel is its lower cost and widespread availability compared to stainless steel. Carbon steel is more economical to produce and is readily available in various grades and forms, making it a cost-effective choice for many applications where corrosion resistance is not a critical factor, such as structural components, machinery parts, and general manufacturing.

Stainless steel, on the other hand, is more expensive due to the addition of alloying elements like chromium and nickel. However, its superior corrosion resistance, durability, and aesthetic appeal can offset the higher initial cost in applications where longevity, low maintenance, and visual appeal are critical factors.

Applications: Tailoring the Material to Your Needs

The choice between stainless steel and carbon steel often depends on the specific application and its requirements. Here are some common applications for each material:

Stainless Steel Applications:

- Food and beverage processing equipment

- Medical and pharmaceutical equipment

- Chemical processing equipment

- Architectural and decorative elements (mirror stainless steel sheets are popular choices)

- Automotive and transportation components

- Cookware and kitchen utensils

- Outdoor furniture and fixtures

Carbon Steel Applications:

- Structural components in construction

- Machinery and equipment parts

- Pipelines and storage tanks

- Automotive and transportation components

- General manufacturing

- Cutting tools and blades

- Hand tools and hardware

Specialized Stainless Steel Solutions from Xinguangyuan

At Xinguangyuan, we specialize in providing high-quality stainless steel solutions for a wide range of industries, including kitchen appliances, medical devices, elevator decoration, doors, hotel decoration, and hardware. Our expertise in stainless steel surface processing techniques, such as polishing, brushing, coloring, mirror surface processing, frosting, drawbenching, glazing, and etching, allows us to create customized finishes that meet your specific aesthetic and functional requirements.

In addition to our flagship mirror 8K stainless steel coil, we offer a comprehensive range of stainless steel products, including decorative plates, screens, and garnitures in different specifications. Our commitment to quality and innovation ensures that our stainless steel solutions not only meet but exceed industry standards, providing exceptional durability, corrosion resistance, and visual appeal.

Choosing the Right Material: Balancing Performance, Cost, and Aesthetics

When selecting between stainless steel and carbon steel, it's crucial to consider factors such as corrosion resistance, strength, durability, appearance, cost, and the specific application requirements. Stainless steel excels in corrosion resistance and aesthetic appeal, making it ideal for applications where these factors are paramount, such as food processing, medical equipment, architectural elements, and consumer products.

Carbon steel, on the other hand, offers superior strength and cost-effectiveness, making it a suitable choice for applications where corrosion resistance is not a critical concern, such as construction, machinery, and general manufacturing. However, it's essential to consider the potential need for protective coatings or regular maintenance to mitigate corrosion risks.

Ultimately, the decision should be based on a careful evaluation of the application's demands, environmental conditions, and long-term cost considerations, including maintenance and replacement costs. By understanding the key differences between these two materials, you can make an informed choice that optimizes performance, durability, cost-effectiveness, and aesthetic appeal for your industrial applications.

Conclusion

In the ever-evolving landscape of industrial materials, the choice between stainless steel and carbon steel remains a critical decision that can significantly impact the success of your projects. While both materials offer unique advantages, it's essential to carefully evaluate your specific requirements and prioritize the factors that matter most to your application.

At Xinguangyuan, we are committed to providing our customers with tailored solutions that meet their unique needs. Our team of experts is dedicated to guiding you through the selection process, ensuring that you choose the right material and surface treatment to achieve the desired performance, durability, and aesthetic appeal.

Whether you require corrosion-resistant stainless steel solutions for harsh environments or high-strength carbon steel components for demanding applications, we have the expertise and resources to deliver exceptional results. Contact us today to learn how our innovative solutions can elevate your products and applications to new heights.