Stainless steel is a versatile material known for its durability, corrosion resistance, and aesthetic appeal. Among the various surface finishes available, mirror finish stainless steel sheets stand out for their stunning reflective appearance and superior properties. In this comprehensive guide, we will explore the benefits, applications, and manufacturing processes of mirror finish stainless steel sheets.

What is Mirror Finish Stainless Steel?

Mirror finish stainless steel, also known as 8K or super mirror finish, is a type of stainless steel sheet that has been polished to achieve an extremely smooth and highly reflective surface. The finish is achieved through a series of polishing and buffing processes using fine abrasives and special polishing compounds.

The resulting surface is virtually free from imperfections and has a mirror-like appearance that reflects images with exceptional clarity. Mirror finish stainless steel sheets are typically made from austenitic grades such as 304 and 316, which contain chromium and nickel for enhanced corrosion resistance.

Benefits of Mirror Finish Stainless Steel Sheets

1. Aesthetic Appeal

One of the primary reasons for choosing mirror finish stainless steel sheets is their stunning visual appearance. The highly reflective surface adds a touch of luxury and sophistication to any application, making it ideal for decorative purposes in architecture, interior design, and consumer products.

2. Corrosion Resistance

Mirror finish stainless steel sheets offer excellent corrosion resistance due to their smooth surface and the presence of chromium and nickel in the alloy. The polished surface minimizes the accumulation of dirt, bacteria, and other contaminants, reducing the risk of corrosion and staining.

3. Hygienic Properties

The smooth, non-porous surface of mirror finish stainless steel makes it easy to clean and sanitize. This property is particularly valuable in applications where hygiene is critical, such as in the food processing, pharmaceutical, and healthcare industries.

4. Durability and Low Maintenance

Mirror finish stainless steel sheets are highly durable and resistant to scratches, dents, and other forms of mechanical damage. The polished surface also requires minimal maintenance, as it is easy to clean and maintain its shine with regular wiping using a soft cloth.

5. Versatility

Mirror finish stainless steel sheets can be cut, bent, shaped, and welded to suit various design requirements. This versatility allows for the creation of intricate and custom designs, making it suitable for a wide range of applications across different industries.

Applications of Mirror Finish Stainless Steel Sheets

1. Architecture and Interior Design

Mirror finish stainless steel sheets are widely used in architectural and interior design applications for their aesthetic appeal and durability. Some common applications include:

- Wall cladding and panels

- Column covers

- Elevator interiors

- Staircase railings and handrails

- Decorative trim and accents

- Signage and logos

2. Food and Beverage Industry

The hygienic properties and corrosion resistance of mirror finish stainless steel make it an ideal choice for the food and beverage industry. Applications include:

- Food processing equipment

- Commercial kitchen appliances

- Beverage dispensers

- Countertops and work surfaces

3. Medical and Pharmaceutical Industry

Mirror finish stainless steel is extensively used in the medical and pharmaceutical industry due to its hygienic properties and ease of cleaning. Common applications include:

- Surgical instruments

- Medical equipment

- Pharmaceutical processing equipment

- Laboratory benches and surfaces

4. Transportation Industry

The durability and corrosion resistance of mirror finish stainless steel make it suitable for use in the transportation industry. Applications include:

- Automotive trim and accessories

- Truck and trailer components

- Railway car interiors

- Marine hardware and fittings

5. Consumer Products

Mirror finish stainless steel is also used in the manufacturing of various consumer products for its aesthetic appeal and durability. Examples include:

- Kitchen appliances and sinks

- Bathroom fixtures and accessories

- Furniture and lighting

- Jewelry and watches

Manufacturing Process of Mirror Finish Stainless Steel Sheets

The manufacturing process of mirror finish stainless steel sheets involves several steps to achieve the desired level of reflectivity and smoothness.

1. Raw Material Selection

The process begins with the selection of high-quality stainless steel coils or sheets, typically in grades 304 or 316. These grades are chosen for their excellent corrosion resistance and formability.

2. Cold Rolling and Annealing

The stainless steel coils or sheets undergo cold rolling to achieve the desired thickness and surface finish. Cold rolling is followed by annealing in a controlled atmosphere to relieve internal stresses and improve the material's formability.

3. Surface Preparation

Before polishing, the surface of the stainless steel sheet is prepared by grinding or sanding to remove any imperfections and create a uniform surface. This step is crucial for achieving a high-quality mirror finish.

4. Polishing

The prepared stainless steel sheet undergoes a series of polishing steps using progressively finer abrasives. The polishing process typically involves the use of polishing belts, brushes, and buffing wheels along with special polishing compounds.

The polishing sequence may include:

- Rough polishing: Using coarse abrasives to remove deep scratches and create a uniform surface.

- Fine polishing: Using finer abrasives to achieve a smoother surface and higher reflectivity.

- Buffing: Using soft cloth mops and polishing compounds to achieve the final mirror finish.

5. Cleaning and Inspection

After polishing, the mirror finish stainless steel sheet is thoroughly cleaned to remove any residual polishing compounds and contaminants. The sheet is then inspected for surface quality, reflectivity, and dimensional accuracy.

6. Packaging and Shipping

The finished mirror finish stainless steel sheets are protected with a removable film or paper to prevent scratches during handling and transportation. The sheets are then packaged and shipped to customers for various applications.

Factors Affecting the Quality of Mirror Finish Stainless Steel Sheets

Several factors can influence the quality and consistency of mirror finish stainless steel sheets:

1. Grade of Stainless Steel

The grade of stainless steel used can impact the final appearance and performance of the mirror finish. Higher grades like 304 and 316 offer better corrosion resistance and formability compared to lower grades.

2. Surface Preparation

Proper surface preparation is essential for achieving a high-quality mirror finish. Any imperfections or irregularities on the surface before polishing can result in visible defects in the final product.

3. Polishing Technique and Equipment

The polishing technique and equipment used can significantly affect the quality and consistency of the mirror finish. Skilled operators and well-maintained equipment are necessary to achieve the desired level of reflectivity and smoothness.

4. Handling and Storage

Mirror finish stainless steel sheets are susceptible to scratches and damage during handling and storage. Proper care must be taken to protect the surface using protective films or paper and to store the sheets in a clean, dry environment.

Choosing the Right Mirror Finish Stainless Steel Sheet

When selecting a mirror finish stainless steel sheet for your application, consider the following factors:

1. Grade of Stainless Steel

Choose the appropriate grade of stainless steel based on the required corrosion resistance, formability, and mechanical properties. Grades 304 and 316 are commonly used for mirror finish applications.

2. Thickness and Size

Determine the required thickness and size of the mirror finish stainless steel sheet based on your application's structural and design requirements. Standard thicknesses range from 0.5mm to 3mm, and sheets can be cut to custom sizes.

3. Protective Film

Opt for mirror finish stainless steel sheets with a protective film or paper to minimize the risk of scratches and damage during handling and transportation. The film should be easily removable without leaving any residue on the surface.

4. Supplier Reputation and Quality Control

Choose a reputable supplier with a proven track record of producing high-quality mirror finish stainless steel sheets. Inquire about their quality control processes and certifications to ensure consistent quality and adherence to industry standards.

Maintenance and Cleaning of Mirror Finish Stainless Steel Sheets

To maintain the appearance and performance of mirror finish stainless steel sheets, follow these maintenance and cleaning guidelines:

1. Regular Cleaning

Clean the surface regularly using a soft, clean cloth dampened with water or a mild detergent solution. Avoid using abrasive cleaners or scouring pads that can scratch the surface.

2. Prompt Removal of Contaminants

Remove any spills, stains, or contaminants from the surface as soon as possible to prevent staining or corrosion. Use a soft cloth or sponge to gently wipe the surface clean.

3. Avoid Harsh Chemicals

Do not use harsh chemicals, acidic cleaners, or bleach on mirror finish stainless steel sheets, as they can damage the surface and cause discoloration.

4. Protect from Scratches

Take care to protect the surface from scratches caused by abrasive objects or improper cleaning methods. Use soft cloths or sponges for cleaning and avoid dragging heavy or sharp objects across the surface.

Conclusion

Mirror finish stainless steel sheets offer a combination of stunning visual appeal, excellent corrosion resistance, hygienic properties, and durability. These qualities make them an ideal choice for a wide range of applications in architecture, interior design, food processing, medical equipment, transportation, and consumer products.

By understanding the benefits, manufacturing processes, and selection criteria for mirror finish stainless steel sheets, you can make informed decisions when specifying this material for your projects. With proper maintenance and care, mirror finish stainless steel sheets can retain their attractive appearance and performance for years to come.

FAQs

-

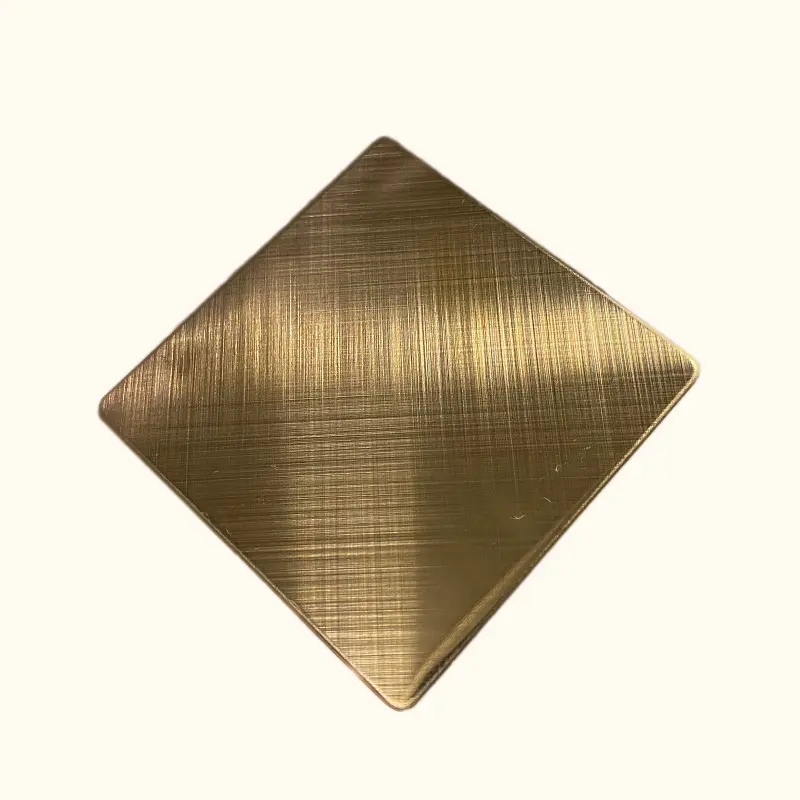

What is the difference between mirror finish and brushed finish stainless steel sheets? Mirror finish stainless steel sheets have a highly reflective, smooth surface, while brushed finish sheets have a unidirectional grain pattern with a less reflective, matte appearance.

-

Can mirror finish stainless steel sheets be welded? Yes, mirror finish stainless steel sheets can be welded using standard welding techniques for stainless steel. However, the welded area may require re-polishing to restore the mirror finish.

-

Are mirror finish stainless steel sheets more expensive than other finishes? Yes, mirror finish stainless steel sheets are generally more expensive than other finishes due to the additional polishing and buffing processes required to achieve the high level of reflectivity and smoothness.

-

Can mirror finish stainless steel sheets be used outdoors? Yes, mirror finish stainless steel sheets can be used outdoors, as they offer excellent corrosion resistance. However, in coastal or highly polluted environments, grade 316 stainless steel is recommended for better performance.

-

How do I remove scratches from mirror finish stainless steel sheets? Minor scratches on mirror finish stainless steel sheets can be removed by polishing the surface with a soft cloth and a non-abrasive metal polish. For deeper scratches, professional re-polishing may be required to restore the mirror finish.