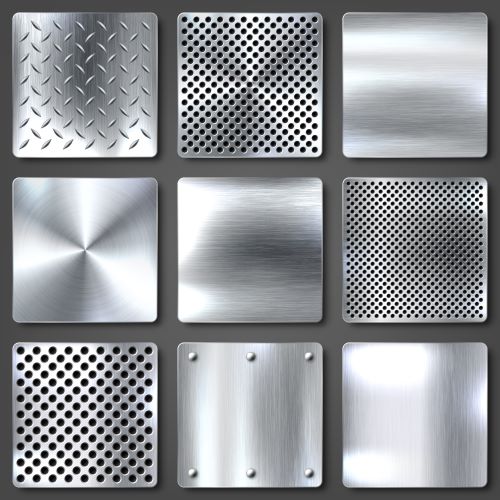

A mirror finish on stainless steel creates a highly reflective, bright surface that enhances both aesthetics and functionality. This premium finish is achieved through meticulous mechanical polishing processes, resulting in a smooth, glossy appearance that's prized across various industries. From sleek kitchen appliances to sterile medical instruments, mirror-finished stainless steel offers a combination of beauty and practicality that's hard to match.

The Art and Science of Mirror Finishing

Achieving a flawless mirror finish requires skill, patience, and attention to detail. Here's a step-by-step breakdown of the process:

-

Surface Preparation: Begin with a smooth, blemish-free stainless steel surface. Remove any weld discoloration, pitting, or major scratches through grinding or abrasive blasting.

-

Rough Polishing: Use a coarse abrasive belt or disc (80-120 grit) to remove remaining scratches and create an even, dull finish across the entire surface.

-

Fine Polishing: Progress through successively finer abrasive grits (240, 320, 400, 600) to continue smoothing and polishing the surface.

-

Buffing: Employ a cotton buffing wheel with a polishing compound to create a mirror-like shine. Apply light pressure and make overlapping passes for consistent results.

-

Final Cleaning: Thoroughly clean the polished surface with a degreasing solvent to remove any polishing compound residue.

Pro Tips:

- Work through abrasive grits gradually to avoid creating new scratches

- Use low rpm and light pressure to prevent overheating the stainless steel

- Consider using a lubricant like soap solution to reduce friction and abrasive loading

- Clean polishing discs/belts frequently to maintain their cutting ability

- Aim for a mirror finish of Ra < 0.2 micrometers for ultimate shine and smoothness

Benefits of Mirror-Finished Stainless Steel

-

Stunning Aesthetics: The high-gloss, reflective surface enhances product appeal and brand image with a sleek, modern look.

-

Easy Maintenance: The smooth surface resists staining and accumulation of dirt, dust, or fingerprints, reducing cleaning time and costs.

-

Improved Durability: The polishing process helps conceal minor scratches and blemishes, potentially extending the product's lifespan.

-

Enhanced Corrosion Resistance: Removing surface imperfections eliminates potential harboring spots for corrosive particles.

-

Superior Hygiene: The non-porous surface facilitates easy cleaning and sterilization, crucial for medical, food-related, and other hygiene-sensitive industries.

Versatile Applications Across Industries

Mirror-finished stainless steel finds its way into a diverse range of products and environments:

- Kitchen Appliances: Refrigerators, ovens, and dishwashers benefit from the sleek look and easy-clean properties.

- Medical Devices: Surgical instruments and implants rely on the material's sterility and corrosion resistance.

- Architectural Elements: From elevator interiors to decorative wall panels, mirror-finished steel adds a touch of luxury.

- Hospitality: Hotels and restaurants use it for everything from bar tops to decorative accents, creating an upscale ambiance.

- Automotive: High-end vehicles incorporate mirror-finished components for both exterior and interior detailing.

- Art and Design: Sculptors and designers leverage the material's reflective properties for striking visual effects.

Xinguangyuan: Mastering the Mirror Finish

Xinguangyuan, a leading manufacturer in the stainless steel industry, has established itself as an expert in creating premium mirror-finished products. Their state-of-the-art facilities and skilled craftsmen specialize in:

- Decorative plates and screens in various sizes and specifications

- Custom architectural elements and garnitures

- Advanced surface processing techniques including frosting, drawbenching, and etching

- Tailored solutions for specific industry requirements

By partnering with Xinguangyuan, businesses can access high-quality mirror-finished stainless steel components that elevate their products' visual appeal while ensuring durability and ease of maintenance.

Conclusion: Reflecting Excellence

The mirror finish on stainless steel represents the pinnacle of surface treatment, combining form and function in a way that few other materials can match. While achieving this finish requires expertise and precision, the results speak for themselves – a gleaming surface that catches the eye and stands up to the rigors of daily use.

Whether you're designing cutting-edge medical equipment, crafting luxury kitchenware, or creating statement architectural pieces, mirror-finished stainless steel offers unparalleled versatility and appeal. By understanding the process, benefits, and applications of this premium finish – and partnering with industry leaders like Xinguangyuan – you can harness the power of reflection to elevate your products and spaces to new heights of sophistication and performance.