Stainless steel is a versatile and popular material used in various industries and applications. It offers excellent corrosion resistance, durability, and aesthetic appeal. However, with so many stainless steel grades available, selecting the perfect one for your unique needs can be difficult. This post will go over seven important aspects to consider when choosing a stainless steel grade.

Corrosion Resistance

Corrosion resistance is a critical factor to consider when choosing a stainless steel grade. Stainless steel's ability to resist corrosion is due to the presence of chromium, which forms a protective layer of chromium oxide on the surface when exposed to oxygen. This layer prevents the underlying metal from corroding.

Austenitic stainless steel grades, such as 304 and 316, are the most prevalent and have good corrosion resistance. These grades are extremely resistant to corrosion caused by water, moisture, and chemicals, making them ideal for a variety of applications such as kitchen equipment, chemical processing facilities, and maritime situations.

For more aggressive or specialized environments, duplex stainless steel grades like 2205 offer superior corrosion resistance. These grades have a balanced microstructure of austenite and ferrite, providing increased strength and resistance to pitting and crevice corrosion.

Strength And Durability

The strength and durability of stainless steel grades vary depending on their composition and microstructure. For typical purposes, the most widely used stainless steel grade is 304, which provides an excellent blend of strength and corrosion resistance. It may be used in a variety of sectors, including construction, architecture, and automobile. The composition and microstructure of stainless steel grades influence their strength and durability.

When considering strength, it's essential to balance it with the intended application. Some grades, like the precipitation-hardening stainless steels, offer exceptional strength but may sacrifice some corrosion resistance. To select the optimum grade for your unique project requirements, always check with materials engineers or specialists.

Temperature Resistance

Stainless steel grades with good temperature resistance are crucial for applications that involve exposure to elevated temperatures or extreme heat. High-temperature applications can produce structural changes in stainless steel, resulting in lower mechanical qualities.

Austenitic stainless steel grades like 310 and 321 are commonly used in applications involving high temperatures, such as furnace components, heat exchangers, and exhaust systems.

For even higher-temperature applications, nickel-based alloys like Inconel and Hastelloy are preferred due to their exceptional high-temperature properties and resistance to oxidation and creep.

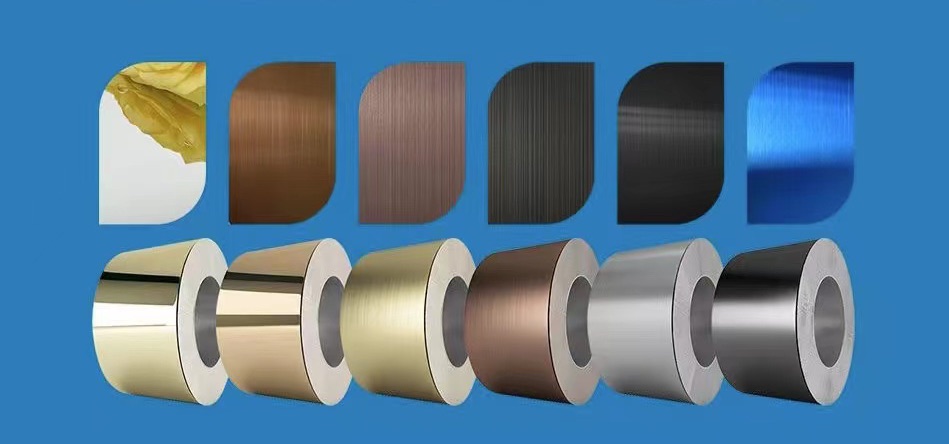

430 China Stainless Steel Coil

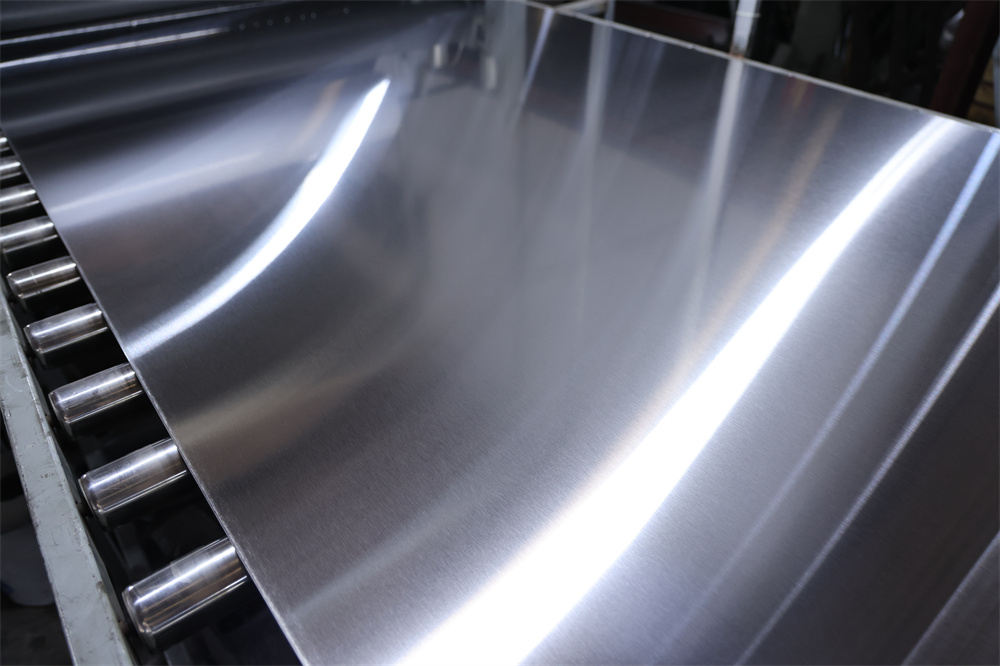

Fabrication And Formability

The ease of fabrication and formability of stainless steel grades impacts their usability in various manufacturing processes. Some grades are more malleable and can be easily formed into complex shapes, while others may require special processing techniques.

Because of their poorer ductility and formability, ferritic stainless steel grades may be more difficult to work with. However, they are often chosen for their magnetic properties, making them suitable for specific applications like magnetic resonance imaging (MRI) equipment.

Cost

Cost is a significant consideration when selecting a stainless steel grade, as it can vary greatly depending on the grade's composition and properties. Generally, austenitic stainless steel grades like 304 are more affordable and widely available, making them a cost-effective choice for many applications.

As the alloying elements increase in stainless steel grades, so does the cost. Nickel and molybdenum are costly components that can improve stainless steel qualities such as corrosion resistance and high-temperature performance.

316 Stainless Steel Sheet Wholesale

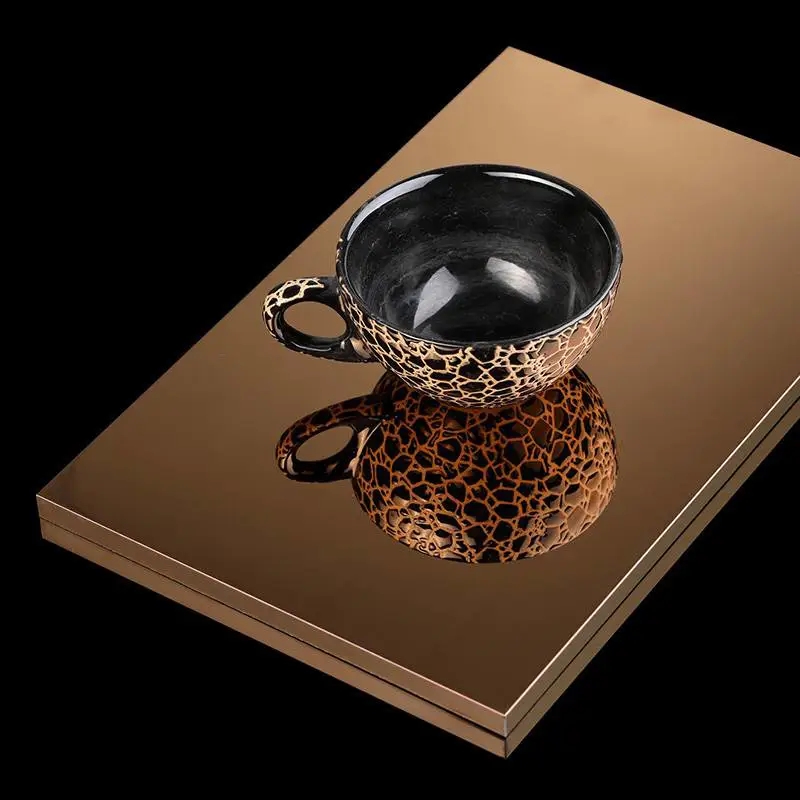

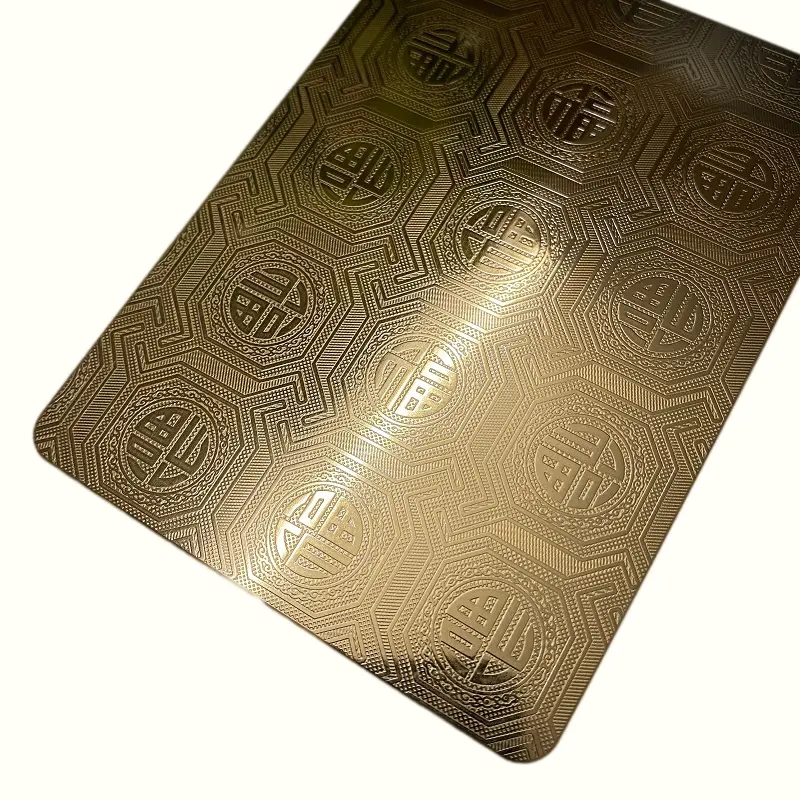

Aesthetic Appeal

Stainless steel is not only valued for its functional properties but also for its aesthetic appeal. Its modern and sleek appearance makes it a popular choice for various decorative and architectural applications.

For applications where aesthetics are crucial, grades with polished or brushed finishes are often selected. These coatings improve the aesthetic attractiveness of stainless steel, making it suited for interior design components, kitchen appliances, and luxury consumer items.

Environmental Impact

As sustainability becomes a growing concern, evaluating the environmental impact of the stainless steel grade becomes essential. Some stainless steel grades contain a higher percentage of recycled materials, making them more eco-friendly.

Choosing ecologically friendly stainless steel grades is consistent with sustainable practices and can benefit projects looking for green building certifications.

Conclusion

Choosing the right stainless steel grade is a critical decision that can significantly impact the performance and longevity of your project. Consider factors above when making your choice. If you are looking for a trusted stainless steel company, XINGUANGYUAN is ideal for you. We offer various products including different grades stainless steel coils and sheets. Contact us for more product details now!