In the ever-evolving world of stainless steel, 430 grade stands out as a versatile and cost-effective choice for a wide range of applications. This comprehensive guide delves deep into the intricacies of 430 stainless steel, providing you with a thorough understanding of its properties, processing techniques, and real-world applications.

What is 430 Stainless Steel?

430 stainless steel is a ferritic grade of stainless steel that derives its corrosion resistance primarily from its chromium content, typically ranging from 16 to 18%. Unlike austenitic grades like 304, 430 stainless steel has a low nickel content, usually less than 0.75%, making it a more economical option for applications where moderate corrosion resistance is required.

Key Properties at a Glance

- Density: 7.62 - 7.82 g/cc

- Yield Strength: 345 MPa (0.2% offset)

- Ultimate Tensile Strength: 517 MPa

- Hardness: 85 HRB

- Modulus of Elasticity: 200 GPa

- Melting Point: 1425 - 1510°C

- Heat Resistance: Good up to 815°C

- Corrosion Resistance: Good in mild atmospheres, water, and some chemicals. Susceptible to pitting in saltwater.

- Formability: Excellent cold formability, can be easily bent, stamped, and drawn.

- Weldability: Fair weldability, requires proper techniques to avoid sensitization.

- Magnetism: Moderately magnetic due to its ferritic structure.

Advantages of 430 Stainless Steel

Corrosion Resistance

One of the key advantages of 430 stainless steel is its good corrosion resistance in mild atmospheric environments, water, and some chemical solutions. Its chromium content forms a passive oxide layer that protects the underlying metal from corrosion. However, it is important to note that 430 stainless steel is susceptible to pitting corrosion in saltwater environments and offers lower resistance to acidic environments compared to austenitic grades like 316 stainless steel.

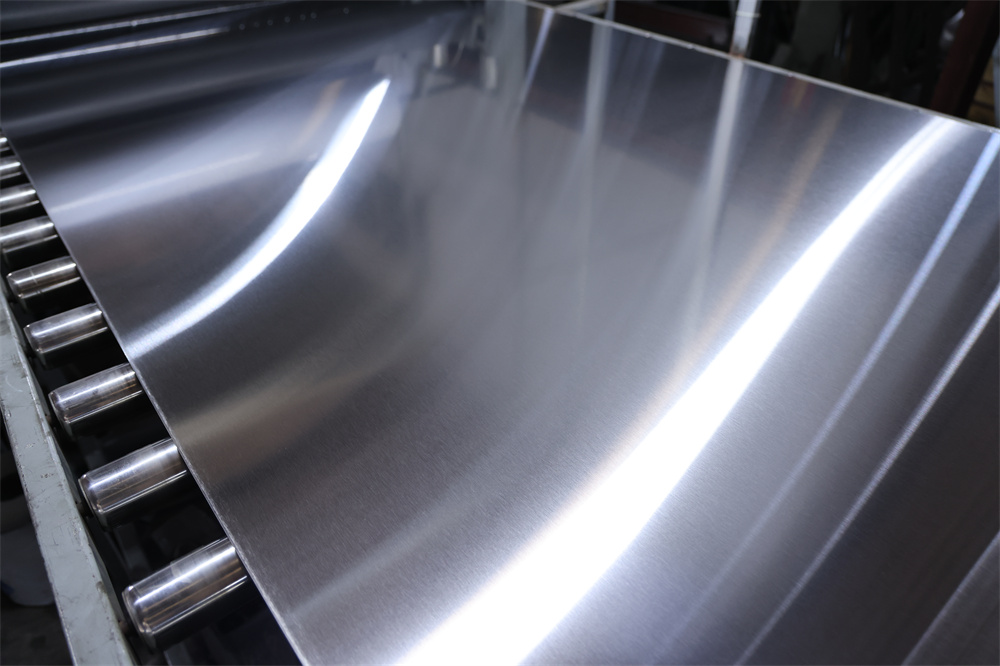

Formability and Weldability

430 stainless steel exhibits excellent cold formability, allowing it to be easily formed into various shapes, including sheets, coils, plates, and fabricated components. It can be bent, stamped, drawn, and roll-formed without much difficulty. Additionally, 430 stainless steel has fair weldability and can be welded using common techniques such as resistance welding, TIG, and MIG welding. However, proper welding techniques and filler materials must be used to avoid sensitization and subsequent intergranular corrosion in the heat-affected zones.

Heat Resistance and Magnetism

430 stainless steel exhibits good heat resistance, making it suitable for intermittent high-temperature exposure up to 815°C without significant scaling or deformation. Its ferritic structure also makes it moderately responsive to magnetic fields, acting as a moderate magnetic flux carrier. This property can be advantageous in applications where magnetic sorting or handling is required.

Applications of 430 Stainless Steel

Due to its unique combination of properties, 430 stainless steel finds applications in various industries, including:

- Kitchen Appliances: Used in sinks, dishwashers, refrigerators, and stove trim due to its corrosion resistance and formability.

- Automotive Trim: Employed in automotive trim components, benefiting from its good formability and moderate corrosion resistance.

- Architectural and Decorative Trim: Utilized in architectural trim and decorative applications, taking advantage of its aesthetic appeal and corrosion resistance.

- Industrial Equipment: Found in various industrial equipment components, leveraging its moderate strength and corrosion resistance.

- Fasteners and Hardware: Used in the production of fasteners, bolts, and hardware, where its magnetic properties can be advantageous.

Xinguangyuan's Expertise in 430 Stainless Steel Solutions

At Xinguangyuan, we specialize in providing high-quality 430 stainless steel products and surface treatments tailored to our clients' specific requirements. Our expertise in surface processing techniques, such as electropolishing, passivation, and specialized coatings, allows us to enhance the corrosion resistance, aesthetics, and functional properties of 430 stainless steel components.

One notable application where Xinguangyuan's 430 stainless steel solutions have excelled is in the medical device industry. By leveraging our advanced surface finishing capabilities, we can produce 430 stainless steel components with exceptional cleanliness, smoothness, and corrosion resistance, meeting the stringent requirements of medical-grade materials.

Processing Techniques for 430 Stainless Steel

Welding Considerations

While 430 stainless steel has fair weldability, it is crucial to follow proper welding techniques to avoid sensitization and subsequent intergranular corrosion. Sensitization occurs when chromium carbides precipitate along the grain boundaries, depleting the surrounding areas of chromium and reducing their corrosion resistance.

To mitigate sensitization, Xinguangyuan recommends the following welding practices for 430 stainless steel:

- Preheating the material to 150-200°C before welding to minimize thermal gradients.

- Using appropriate filler materials, such as 308L, 309, 310, or 312 stainless steel, to maintain corrosion resistance in the weld zone.

- Post-weld annealing at 790-815°C to relieve embrittlement and restore corrosion resistance in the heat-affected zones.

Surface Finishing and Treatments

At Xinguangyuan, we offer a range of surface finishing and treatment options to enhance the properties and performance of 430 stainless steel components. Some of our specialized services include:

- Electropolishing: This process removes surface imperfections and creates a smooth, mirror-like finish, improving corrosion resistance and cleanability.

- Passivation: Enhances the passive oxide layer on the surface, increasing corrosion resistance and ensuring consistent performance.

- Specialized Coatings: We can apply various coatings, such as PVD, CVD, or ceramic coatings, to improve wear resistance, hardness, or aesthetic properties.

By leveraging our expertise in surface processing, we can tailor the properties of 430 stainless steel to meet the specific requirements of our clients across various industries, including medical, aerospace, and consumer products.

Addressing Challenges with 430 Stainless Steel

Sensitization and Intergranular Corrosion

As mentioned earlier, sensitization can occur in 430 stainless steel due to the precipitation of chromium carbides along grain boundaries, leading to intergranular corrosion. This phenomenon is particularly prevalent when the material is exposed to temperatures between 400-600°C for prolonged periods.

To mitigate sensitization, Xinguangyuan recommends proper heat treatment practices, such as solution annealing or stabilization annealing, to dissolve or stabilize the chromium carbides. Additionally, our surface finishing techniques, like electropolishing and passivation, can help restore the passive oxide layer and improve corrosion resistance in sensitized areas.

Pitting Corrosion in Saltwater Environments

While 430 stainless steel exhibits good corrosion resistance in mild environments, it is susceptible to pitting corrosion in saltwater or chloride-rich environments. This limitation should be considered when selecting materials for applications exposed to marine or coastal conditions.

To address this challenge, Xinguangyuan offers specialized coatings and surface treatments that can enhance the corrosion resistance of 430 stainless steel components in harsh environments. Our team of experts can recommend the most suitable solution based on the specific application and operating conditions.

Conclusion

430 stainless steel is a versatile and cost-effective material that offers a unique combination of properties, including moderate corrosion resistance, excellent formability, and fair weldability. By understanding its characteristics, processing techniques, and potential challenges, manufacturers can leverage the advantages of 430 stainless steel while mitigating its limitations.

At Xinguangyuan, we are committed to providing our clients with high-quality 430 stainless steel products and tailored surface solutions. Our expertise in surface processing, combined with our deep understanding of material properties, allows us to optimize the performance and functionality of 430 stainless steel components for a wide range of applications.

Whether you require corrosion-resistant kitchen appliances, decorative automotive trim, or medical-grade components, Xinguangyuan has the capabilities to deliver innovative and reliable 430 stainless steel solutions. Contact us today to discuss your specific requirements and explore how we can help you achieve your project goals.

Key Takeaways

- 430 stainless steel offers a unique combination of moderate corrosion resistance, excellent formability, and fair weldability.

- Its ferritic structure provides moderate magnetic properties, making it suitable for applications requiring magnetic sorting or handling.

- Proper welding techniques and heat treatments are crucial to avoid sensitization and intergranular corrosion.

- Xinguangyuan specializes in surface treatments and coatings to enhance the properties and performance of 430 stainless steel components.

- Our expertise in the medical device industry ensures we meet the stringent requirements for medical-grade materials.

- Contact us to explore how our 430 stainless steel solutions can benefit your specific application and industry.

Are you looking for high-quality 430 stainless steel products or specialized surface treatments? Look no further than Xinguangyuan. Our team of experts is ready to assist you in finding the perfect solution for your project. Contact us today to discuss your requirements and learn how we can help you achieve your goals.