In the ever-evolving world of stainless steel, the 316 grade stands as a true testament to exceptional corrosion resistance and durability. This comprehensive guide delves deep into the realm of 316 stainless steel sheets, unveiling their unique properties, versatile applications, and the intricate manufacturing processes that bring them to life.

Understanding the Essence of 316 Stainless Steel

316 stainless steel, also known as marine grade stainless steel, is an austenitic chromium-nickel alloy that boasts superior corrosion resistance compared to other stainless steel grades. Its composition includes molybdenum, a crucial element that enhances its ability to withstand harsh environments, making it an ideal choice for applications where exposure to saltwater, chemicals, or extreme temperatures is a concern.

Chemical Composition: The Key to Unparalleled Performance

The chemical composition of 316 stainless steel is a carefully balanced blend of elements that contribute to its remarkable properties:

- Chromium (16-18%): Provides excellent corrosion resistance by forming a passive oxide layer on the surface, acting as a protective barrier against corrosive agents.

- Nickel (10-14%): Enhances the austenitic structure, improving ductility and toughness, ensuring the material can withstand significant stress and deformation without compromising its integrity.

- Molybdenum (2-3%): Increases resistance to pitting and crevice corrosion, particularly in chloride environments, making 316 stainless steel an exceptional choice for marine and coastal applications.

- Carbon (0.08% maximum): Helps control strength and hardness, contributing to the overall durability and wear resistance of the material.

This unique blend of elements results in a material that not only exhibits unparalleled corrosion resistance but also boasts exceptional strength, ductility, and weldability, making it a versatile choice for a wide range of applications.

Unveiling the Versatile Applications of 316 Stainless Steel Sheets

The exceptional properties of 316 stainless steel sheets have made them a popular choice across various industries, where durability and corrosion resistance are paramount. Here are some of the most common applications:

-

Marine and Offshore Industries: Due to its exceptional resistance to saltwater corrosion, 316 stainless steel sheets are widely used in the construction of ships, offshore platforms, and other marine structures. These sheets can withstand the harsh conditions of the ocean environment, ensuring long-lasting performance and minimizing maintenance requirements.

-

Chemical Processing: The chemical industry relies heavily on 316 stainless steel sheets for their ability to withstand exposure to harsh chemicals, acids, and solvents. These sheets are commonly used in the construction of equipment, piping, and storage tanks, ensuring safe and reliable operations in demanding environments.

-

Food and Beverage: The non-toxic and hygienic properties of 316 stainless steel sheets make them suitable for food processing equipment, kitchen appliances, and brewing systems. Their corrosion resistance and ease of cleaning ensure that food and beverages remain free from contamination, meeting stringent health and safety standards.

-

Architectural and Decorative Applications: The sleek and modern appearance of 316 stainless steel sheets, combined with their durability, has led to their widespread use in architectural cladding, decorative panels, and interior design elements. These sheets not only add a touch of elegance but also withstand the test of time, maintaining their aesthetic appeal for years to come.

-

Medical and Pharmaceutical Industries: The corrosion resistance and ease of sterilization make 316 stainless steel sheets a preferred choice for medical equipment, surgical instruments, and pharmaceutical processing equipment. Their ability to maintain a hygienic environment is crucial in these industries, where cleanliness and safety are of utmost importance.

-

Automotive and Aerospace: The strength and corrosion resistance of 316 stainless steel sheets make them suitable for various automotive and aerospace components, such as exhaust systems, fasteners, and structural elements. These sheets can withstand extreme temperatures, vibrations, and harsh environmental conditions, ensuring reliable performance and extended service life.

Mastering the Art of Manufacturing 316 Stainless Steel Sheets

The production of 316 stainless steel sheets involves a series of intricate processes, each designed to ensure the highest quality and consistency. Here's an overview of the manufacturing process:

-

Melting and Casting: The raw materials, including chromium, nickel, molybdenum, and other alloying elements, are melted in an electric arc furnace or a basic oxygen furnace. The molten metal is then cast into semi-finished forms, such as ingots or slabs.

-

Hot Rolling: The cast ingots or slabs are heated and passed through a series of rolling mills, where they are gradually reduced in thickness to form hot-rolled coils or plates.

-

Annealing and Pickling: The hot-rolled material undergoes annealing, a heat treatment process that relieves internal stresses and improves ductility. Subsequently, the material is pickled, a chemical process that removes surface oxides and contaminants, ensuring a clean and uniform surface for further processing.

-

Cold Rolling: The annealed and pickled material is further reduced in thickness through a series of cold rolling mills, resulting in the desired final thickness and surface finish. This process imparts superior strength and dimensional accuracy to the sheets.

-

Finishing Operations: Depending on the application, the cold-rolled sheets may undergo additional finishing operations, such as cutting, polishing, etching, or surface treatments like hairline finishing or PVD coating. These processes enhance the aesthetic appeal and functional properties of the sheets, tailoring them to specific application requirements.

-

Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the 316 stainless steel sheets meet the required specifications and industry standards. Strict adherence to quality protocols guarantees consistent performance and reliability.

Unveiling the Beauty: Surface Finishes and Treatments

316 stainless steel sheets are available in various surface finishes and treatments, each offering unique aesthetic and functional properties. Some of the most common finishes include:

-

Mill Finish: This is the natural finish resulting from the final cold rolling process, characterized by a dull, matte appearance. It provides a clean and uniform surface, often preferred for industrial or functional applications.

-

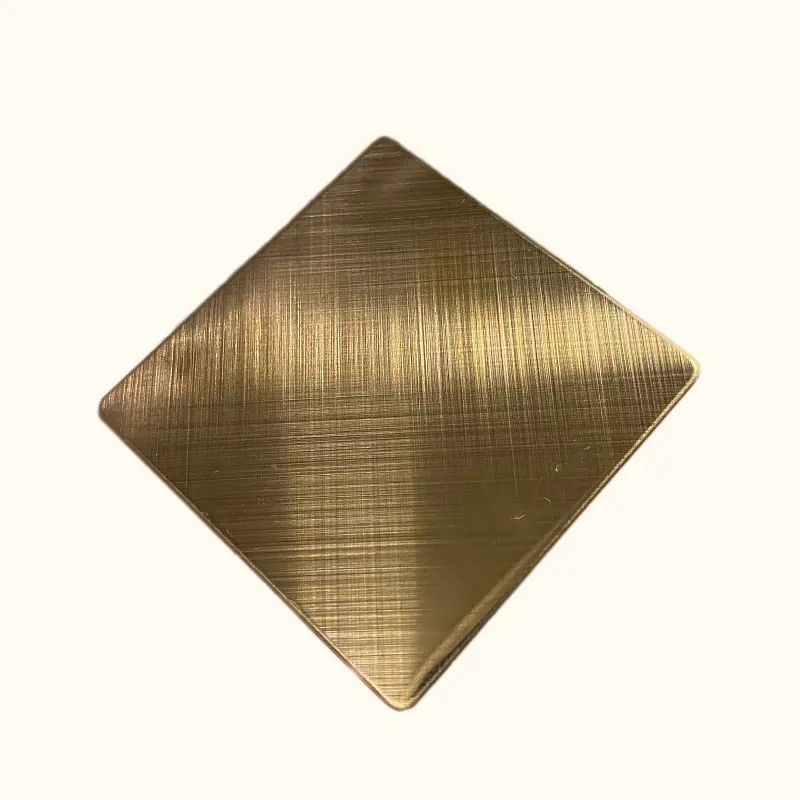

Hairline Finish: Also known as brushed finish, this surface treatment creates a directional grain pattern that adds a sleek and modern look to the sheets. The hairline finish is achieved through a specialized brushing process, imparting a subtle yet elegant texture to the material.

-

Mirror Finish: Achieved through extensive polishing, this finish provides a highly reflective, mirror-like surface that is often used for decorative applications. The mirror finish adds a touch of sophistication and elegance, making it a popular choice for architectural and interior design projects.

-

Etched Finish: Chemical etching creates intricate patterns or designs on the surface of the sheets, adding a unique and decorative touch. This finish is highly customizable, allowing for the creation of personalized and distinctive designs.

-

PVD Coating: Physical Vapor Deposition (PVD) is a process that applies a thin, colored coating to the surface of the sheets, offering a wide range of color options while maintaining the corrosion resistance of the base material. PVD coatings provide a unique and eye-catching appearance, expanding the design possibilities for architectural and decorative applications.

These finishes and treatments not only enhance the aesthetic appeal of 316 stainless steel sheets but also provide additional functional benefits, such as improved cleanability, slip resistance, or enhanced durability, tailoring the material to meet specific project requirements.

Sustainability and Environmental Responsibility

As the demand for sustainable and eco-friendly materials continues to grow, the stainless steel industry has made significant strides in reducing its environmental impact. 316 stainless steel sheets are highly recyclable, and their durability and corrosion resistance contribute to a longer lifespan, reducing the need for frequent replacements and minimizing waste.

Many manufacturers of 316 stainless steel sheets have implemented sustainable practices, such as using recycled materials, optimizing energy consumption, and minimizing waste during the production process. Additionally, the corrosion resistance of 316 stainless steel sheets reduces the need for frequent maintenance and replacement, further contributing to a lower environmental footprint.

At Xinguangyuan Stainless Steel Co., Ltd., we are committed to sustainable manufacturing practices and prioritize environmental responsibility. Our state-of-the-art facilities and skilled workforce ensure that our products meet the highest quality standards while minimizing our carbon footprint.

Choosing the Right Supplier: Xinguangyuan Stainless Steel Co., Ltd.

When sourcing 316 stainless steel sheets, it is crucial to partner with a reputable and experienced supplier. Look for manufacturers that adhere to industry standards, employ stringent quality control measures, and prioritize sustainable practices.

At Xinguangyuan Stainless Steel Co., Ltd., we take pride in being a leading supplier of high-quality 316 stainless steel sheets. Our commitment to excellence is reflected in our state-of-the-art manufacturing facilities, skilled workforce, and unwavering dedication to customer satisfaction.

We offer a wide range of 316 stainless steel sheet products, including hairline finishes, mirror finishes, etched finishes, and PVD coatings. Our team of experts is always available to assist you in selecting the right product for your specific application and to provide guidance on maintenance and care.

Explore our product range or contact us today to learn more about how we can help bring your vision to life with the exceptional quality of 316 stainless steel sheets.

In conclusion, 316 stainless steel sheets are a remarkable material that combines superior corrosion resistance, durability, and aesthetic appeal. Whether you're in the marine, chemical processing, food and beverage, architectural, or medical industry, these sheets offer a versatile and reliable solution. By understanding their unique properties, manufacturing processes, and surface finishes, you can make an informed decision and unlock the full potential of this exceptional material.