Stainless steel is a popular material used in a variety of industries, including construction, automotive, and food processing. Its corrosion-resistant properties make it a preferred choice for applications where durability and longevity are important. Stainless steel sheets are commonly used in the production of kitchen appliances, automotive parts, and construction materials. Keep reading the post and explore the production process of stainless steel sheets.

Production Process

The production process of stainless steel sheets involves several stages, including melting, casting, rolling, and annealing.

Melting

The raw ingredients are melted in the initial stage of the manufacturing process. Stainless steel is created by precisely mixing iron, chromium, nickel, and other trace metals. The raw materials are melted in a furnace at high temperatures, usually around 1700°C. After that, the molten steel is moved to a ladle and refined to eliminate impurities and undesired components.

Casting

After the steel has been refined, it is cast into large slabs or billets using a continuous casting process. In this process, the molten steel is poured into a water-cooled mold, where it solidifies into a long, continuous strand. A cutting machine is then used to cut the strand into individual slabs or billets.

Stainless Steel Sheet Metal Supplier

Rolling

Once the slabs or billets have been cast, they are heated to a temperature of around 1200°C and rolled into thin sheets using a series of rolling mills. The rolling process involves passing the steel through a series of rollers, which gradually reduce its thickness to the desired level. To achieve equal thickness and surface smoothness, the sheets are rolled in both directions.

Annealing

After the sheets have been rolled, they are annealed to improve their mechanical properties and remove any stresses that may have been introduced during the rolling process. Annealing entails heating the sheets to roughly 1050°C and maintaining them at that temperature for a specific amount of time. This procedure causes the steel to recrystallize and soften, making it simpler to deal with.

430 Stainless Steel Sheet Supplier

Finishing Techniques

Once the sheets have been annealed, they are ready for finishing. There are several finishing techniques that can be used to achieve different surface finishes and textures.

No. 1 Finish

The most prevalent surface treatment for stainless steel sheets is the No. 1 finish. It is made by hot-rolling the sheets to roughly 3mm thickness and then annealing them. The end effect is a drab, matte finish with a slightly rough feel.

No. 2B Finish

The No. 2B finish is produced by cold-rolling the sheets to a thickness of around 0.5mm and then annealing them. The resulting finish is a smooth, reflective surface with a slightly matte texture.

No. 2D Finish

The No. 2D finish is achieved by cold rolling the sheets to roughly 0.5mm thickness and then annealing them. The finished product has a somewhat rough surface with a matte feel.

201 Stainless Steel Sheet Manufacturer

No. 3 Finish

The No. 3 finish is produced by grinding the surface of the sheet using a series of abrasives until a uniform, semi-reflective finish is achieved.

No. 4 Finish

The No. 4 finish is produced by grinding the surface of the sheet using a series of abrasives until a uniform, reflective finish is achieved.

Satin Finish

The satin finish is achieved by using a series of abrasives to create a smooth, matte surface with a slight sheen. It is commonly used in the production of decorative applications.

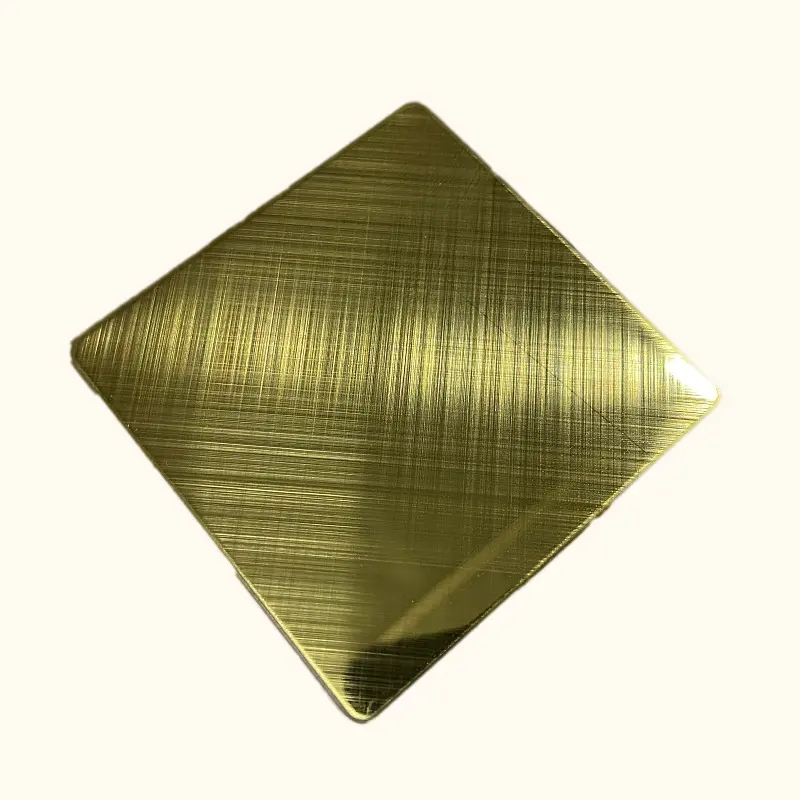

Brushed Finish

The brushed finish is produced by brushing the surface of the sheet with a wire brush, creating a textured surface with a matte appearance.

Conclusion

The manufacturing process of stainless steel sheets involves several stages, including melting, casting, rolling, annealing, and finishing. If you are looking for a reliable stainless steel sheet factory, XINGUANGYUAN is your great choice! Contact us and get more product details!