Stainless steel sheets are among the most versatile materials in construction, architecture, manufacturing, and interior design. One of the key factors that determines their performance and appearance is the surface finish. Different finishes are created through polishing, brushing, or chemical treatment, giving stainless steel sheets a unique look and functionality.

Whether it is for aesthetic appeal, hygiene, or durability, selecting the right stainless steel surface finish is essential. Leading suppliers such as XINGUANGYUAN provide a wide range of stainless steel sheets and coils with customized finishes that meet the needs of industries worldwide.

In this article, we will explore the most common stainless steel sheet finishes, their applications, and practical tips for choosing the right type for your project.

Why Surface Finish Matters in Stainless Steel Sheets

The surface finish of stainless steel sheets does much more than add visual appeal. It directly impacts performance, including:

-

Corrosion Resistance – Polished or passivated surfaces improve protection in harsh environments.

-

Cleanability – Smooth finishes are easier to maintain in food processing and medical industries.

-

Reflectivity and Aesthetics – Architectural projects often require reflective or decorative finishes.

-

Friction and Wear – Certain finishes provide better resistance to scratches and mechanical stress.

Choosing the right finish ensures the stainless steel sheet meets both functional and design requirements.

Common Stainless Steel Sheet Finishes and Their Uses

1. 2B Finish

The 2B finish is the most widely used in industrial applications. It is smooth, reflective, and has a grayish tone.

Applications:

-

Chemical processing equipment

-

Food and beverage manufacturing

-

Pharmaceutical facilities

Its cleanability and corrosion resistance make it a reliable choice for industries requiring hygienic surfaces.

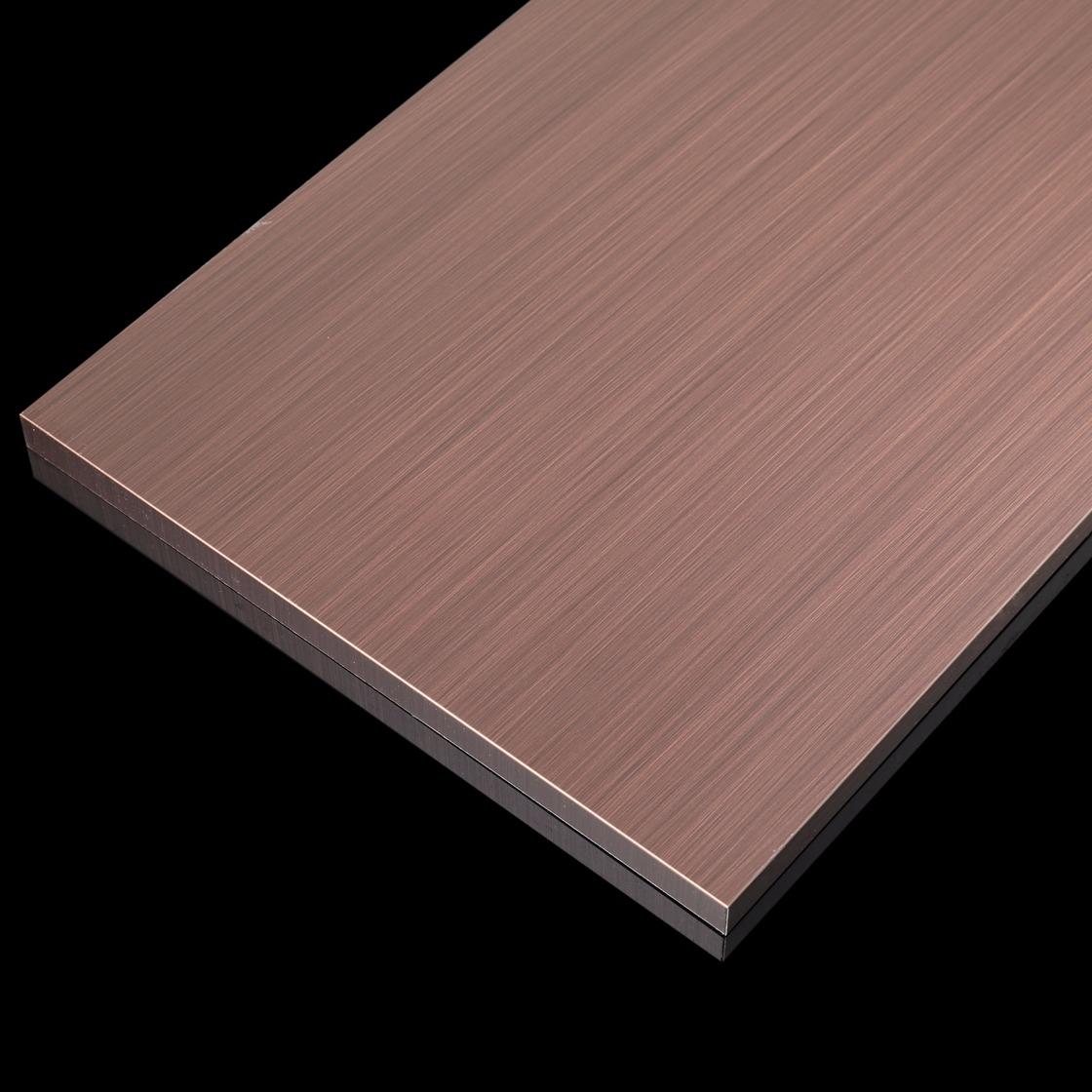

2. No. 4 Brushed Finish

The No. 4 finish, also known as a brushed finish, has a matte look with fine parallel lines. It reduces glare while providing a sleek, modern appearance.

Applications:

-

Kitchen appliances and countertops

-

Elevator doors and wall panels

-

Architectural interiors

This finish is popular in commercial buildings and modern kitchens due to its balance of durability and design.

3. BA (Bright Annealed) Finish

The Bright Annealed (BA) finish is smooth and reflective, achieved through annealing in a controlled atmosphere. It is shinier than 2B but not as reflective as mirror finishes.

Applications:

-

Automotive parts

-

Decorative panels

-

Architectural trim

The BA finish is often chosen where a high-quality reflective surface is needed at a reasonable cost.

4. No. 8 Mirror Finish

The No. 8 finish is also known as a mirror finish. It provides a flawless, highly reflective surface.

Applications:

-

Luxury architecture (facades, lobbies)

-

Interior decorative panels

-

Retail displays and signage

Mirror-polished stainless steel sheets are widely used in high-end design projects where aesthetics are a priority.

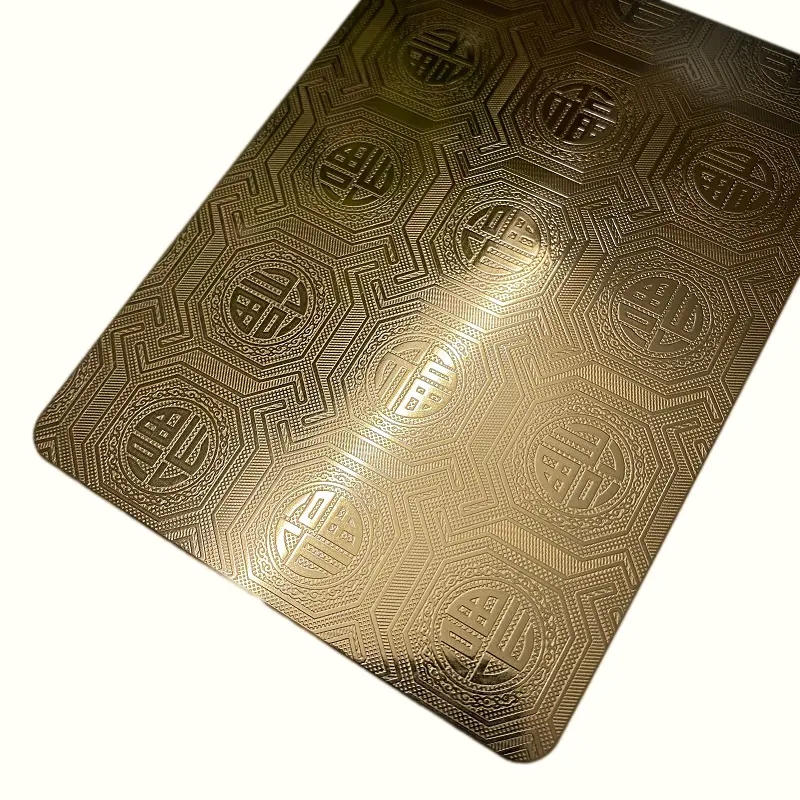

5. Embossed Finish

Embossed stainless steel sheets are created with patterns or textures pressed into the surface.

Applications:

-

Decorative wall cladding

-

Elevator interiors

-

Public infrastructure and art installations

The embossed finish is valued for its scratch resistance and ability to enhance visual impact in public spaces.

6. Satin or Hairline Finish

Satin or hairline finishes create long, continuous polishing lines across the sheet. They deliver a softer, elegant look compared to brushed finishes.

Applications:

-

Hotel lobbies and luxury interiors

-

Furniture accents

-

Architectural features requiring subtle beauty

This finish is often used in premium commercial projects where aesthetics matter as much as functionality.

Factors to Consider When Choosing a Finish

When selecting the right stainless steel sheet finish, consider:

-

Application Environment – Outdoor projects require corrosion-resistant finishes like No. 4 or No. 8.

-

Maintenance Needs – Smooth finishes like 2B and BA are easier to clean.

-

Aesthetic Requirements – Architects may prefer decorative finishes such as mirror or embossed.

-

Cost and Availability – Some finishes, like mirror-polished stainless steel sheets, are more expensive but add high visual value.

Role of Stainless Steel Grades in Finishes

Surface finishes also depend on the grade of stainless steel:

-

304 Stainless Steel Sheets – Widely used for interiors, kitchens, and decorative applications.

-

316 Stainless Steel Sheets – Preferred for marine, chemical, and outdoor projects requiring higher corrosion resistance.

Suppliers like XINGUANGYUAN offer both 304 and 316 stainless steel sheets with multiple finish options to match industrial and architectural requirements.

Why Choose XINGUANGYUAN for Stainless Steel Sheets?

Selecting the right supplier is just as important as choosing the right finish. XINGUANGYUAN has built a reputation as a trusted stainless steel sheet and coil supplier, providing:

-

A wide variety of surface finishes.

-

High-quality stainless steel sheets in 304, 316, and other grades.

-

Customization to meet architectural, industrial, and decorative needs.

-

Reliable bulk supply for international buyers.

By partnering with XINGUANGYUAN, businesses gain access to stainless steel sheets that are not only durable and functional but also elevate the aesthetic value of their projects.

Conclusion

From industrial equipment to luxury architecture, stainless steel sheets are indispensable materials. Their surface finishes—whether reflective, matte, or decorative—play a crucial role in determining both performance and appearance.

By understanding the differences between finishes such as 2B, No. 4 brushed, BA, mirror, embossed, and satin, businesses and architects can make informed decisions that enhance durability and design.

For those sourcing high-quality stainless steel sheets, XINGUANGYUAN stands out as a reliable stainless steel sheet supplier offering a wide range of finishes to suit every application. Choosing the right finish and supplier ensures projects not only meet technical requirements but also achieve long-lasting beauty.