Stainless steel is a versatile and frequently used material noted for its corrosion resistance, durability, and aesthetic appeal. It is used in a variety of areas, including building, manufacturing, and healthcare. Understanding the different stainless steel grades is crucial for choosing the right material for a specific application. This guide aims to provide a comprehensive overview of stainless steel grades, their characteristics, and common uses.

What Is Stainless Steel?

Stainless steel is a type of steel alloy containing a minimum of 10.5% chromium, which forms a protective oxide layer on its surface, preventing rust and corrosion. Other alloying elements improve its mechanical qualities, making it ideal for a wide range of applications.

316 Stainless Steel Sheet Factory

Common Stainless Steel Grades

Austenitic Stainless Steels (300 Series)

Grade 304

Characteristics: Grade 304 is a non-magnetic stainless steel with excellent corrosion resistance. It is resistant to a wide range of chemicals and is easily formable.

Common Uses: Widely used in kitchen equipment, architectural applications, and food processing machinery.

Grade 316

Characteristics: Molybdenum in Grade 316 provides exceptional corrosion resistance in severe conditions, particularly against chlorides.

Common Uses:Preferred in marine applications, pharmaceuticals, and chemical processing due to its enhanced corrosion resistance.

201 Stainless Steel Sheet Factory

Ferritic Stainless Steels (400 Series)

Grade 430

Characteristics: Grade 430 is a straight-chromium stainless steel that is non-hardenable and has high corrosion resistance and formability.

Common Uses: Frequently used in decorative applications like kitchen appliances, automotive trim, and indoor architectural elements.

Martensitic Stainless Steels

Grade 410

Characteristics: Known for its high strength, hardness, and wear resistance, Grade 410 is a martensitic stainless steel.

Common Uses:Widely utilized in cutlery, knives, and surgical instruments where hardness and corrosion resistance are critical.

Duplex Stainless Steels

Grade 2205

Characteristics: A duplex stainless steel combining austenitic and ferritic properties, Grade 2205 offers excellent corrosion resistance and high strength.

Common Uses: Used in chemical processing, oil and gas industries, and marine environments where a combination of strength and corrosion resistance is required.

Factors Influencing Grade Selection

Corrosion Resistance

Considerations: The level of corrosion resistance required depends on the environment. For highly corrosive environments, such as coastal areas, a grade like 316 is preferable.

Temperature Resistance

Considerations:Some applications involve exposure to elevated temperatures. Choosing a grade with good high-temperature resistance, like 310 stainless steel, is crucial.

Strength And Durability

Considerations: Structural applications demand high strength. Grades like 17-4 PH offer a combination of high strength and corrosion resistance.

Formability And Weldability

Considerations: Depending on the fabrication process, selecting a grade with good formability and weldability is essential. Austenitic grades like 304 are often chosen for their formability.

.jpg)

316 Stainless Steel Coil Factory

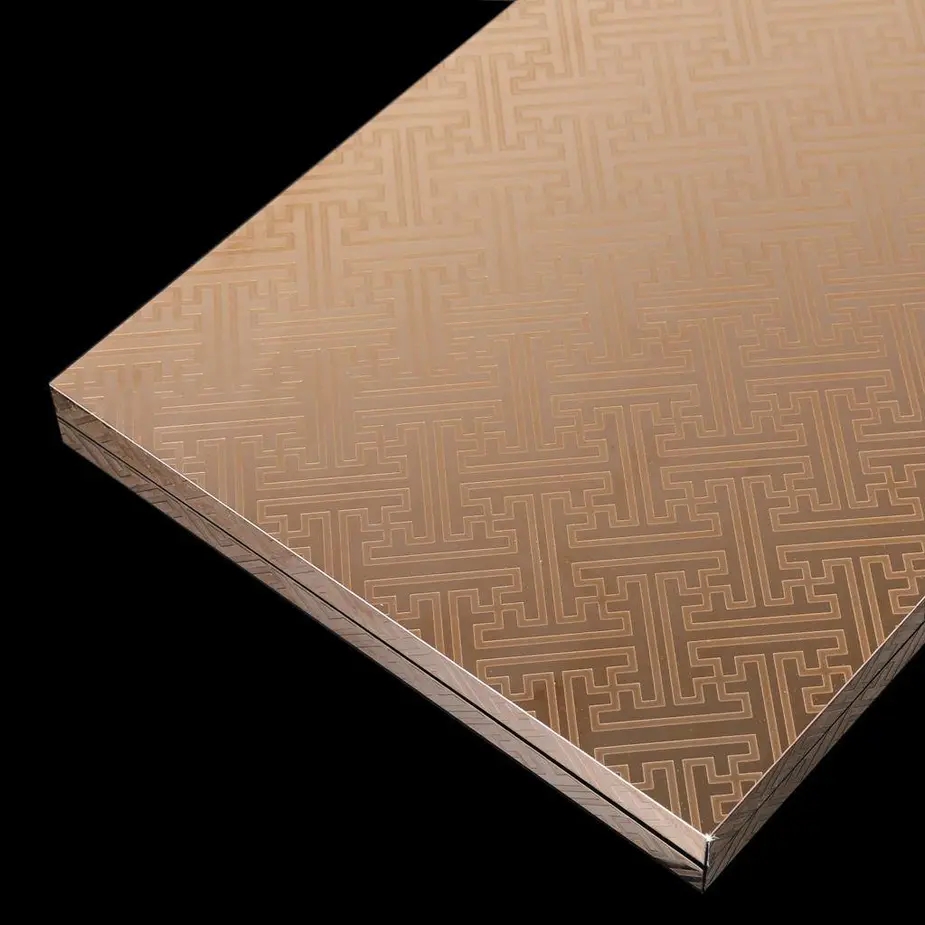

Surface Finishes

Stainless steel's appearance is often as important as its performance. Surface finishes vary in appearance and function, ranging from the high-gloss appeal of polished finishes to the more utilitarian appearance of brushed or matte surfaces.

Maintenance And Care

Proper stainless steel maintenance improves its longevity and function. Regular cleaning with mild detergents, avoiding abrasive cleaners, and addressing any surface contamination promptly will preserve its appearance and corrosion resistance over time. In severe conditions, regular inspection and maintenance are very important.

Conclusion

The selection of the proper stainless steel grade is critical to the success of any project or application. Consider the environmental conditions, mechanical requirements, and aesthetic preferences when selecting a grade. If you are looking for different grades of stainless steel products, XINGUANGYUAN can help you. Contact us for more product details.

FAQs

1. Why is Grade 304 Stainless Steel Commonly Used in Kitchen Appliances?

Answer: Grade 304 stainless steel is popular in kitchen appliances due to its excellent corrosion resistance, making it resistant to the acidic and corrosive nature of many foods. Its non-magnetic properties and ease of formability also contribute to its widespread use in kitchen equipment.

2. What Sets Duplex Stainless Steel (Grade 2205) Apart from Other Grades?

Answer: Duplex stainless steel, such as Grade 2205, stands out for its unique combination of both austenitic and ferritic properties. This dual-phase structure provides exceptional corrosion resistance, high strength, and improved stress corrosion cracking resistance. It is commonly chosen for applications in chemical processing, oil and gas, and marine environments.

3. How Do I Choose the Right Stainless Steel Grade for High-Temperature Applications?

Answer: For high-temperature applications, consider grades with elevated temperature resistance, such as Grade 310. This austenitic stainless steel offers excellent oxidation resistance at high temperatures, making it suitable for applications involving heat, such as furnace parts and exhaust systems.