When it comes to fabricating durable and corrosion-resistant parts, stainless steel sheet metal stands out as a material of choice in various industries, from construction and automotive to aerospace and kitchenware. Bending stainless steel, particularly grades like 304 which combine formability and strength, requires a nuanced approach to preserve its integrity while achieving the desired shape. In this comprehensive guide, we'll explore the intricacies of bending stainless steel sheets, ensuring that you're equipped with the knowledge to perform precise and accurate bends. Whether you're a seasoned metalworker or a DIY enthusiast, these insights will help you navigate the challenges of bending this robust material.

7 Steps To Bend Stainless Steel Sheet

Before we dive into the process of bending stainless steel sheets, it is essential to gather the necessary tools and materials including Stainless steel sheets, Metal brakes, Clamps, Safety equipment, Marking tools, and Cutting tools. After preparing, let's dive into how to bend stainless steel sheets.

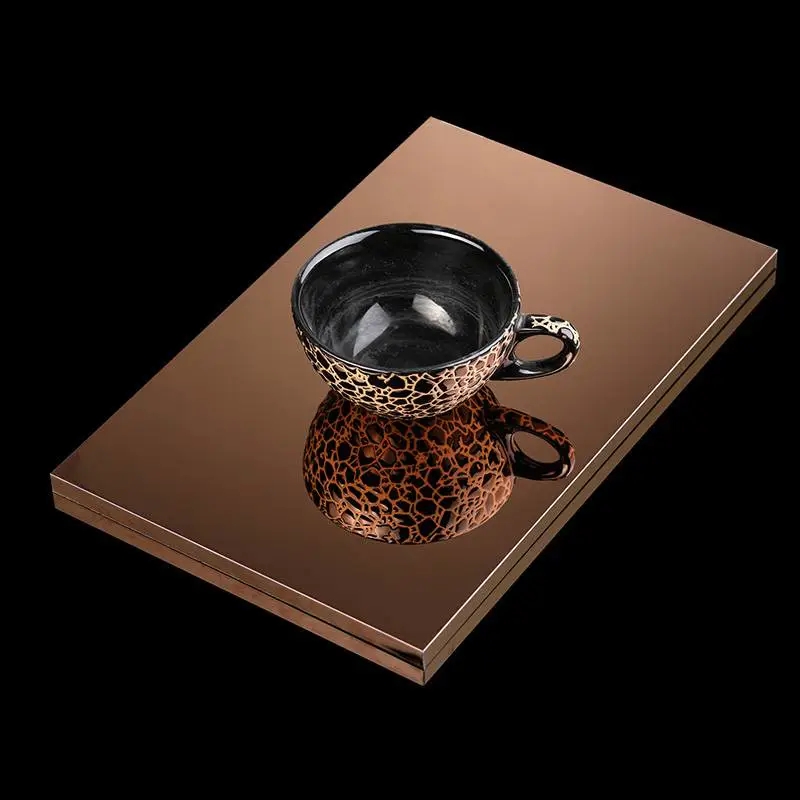

Stainless Steel Decorative Sheets

Step 1: Measure and Mark the Bend Line Accurately

Initiating the bending process begins with an accurate measurement and marking of the bend line. Utilize a precision ruler or a scribe alongside a measuring tape to delineate the bend line on your stainless steel sheet. Accuracy here is critical; ensure the line is not only straight but also corresponds precisely to the intended bend angle. This initial step is fundamental to achieving the perfect bend, especially when working with resilient materials like 304 stainless steel.

Step 2: Secure The Sheet In Place

Once you have marked the bend line, secure the stainless steel sheet using clamps. Make sure the clamps are tight enough to hold the sheet firmly in place without warping it.

Step 3: Execute the Initial Bend with Precision

Employ a metal brake to execute the initial bend along the pre-marked line on the stainless steel sheet. Aim for an initial bend angle that's slightly less than your target to allow for any spring-back, a common occurrence with stainless steel, particularly with the 304 grade. The angle should be approximately 90 degrees or slightly less, depending on your project's specific requirements. Apply consistent and even pressure on the metal brake to achieve a crisp and controlled bend.

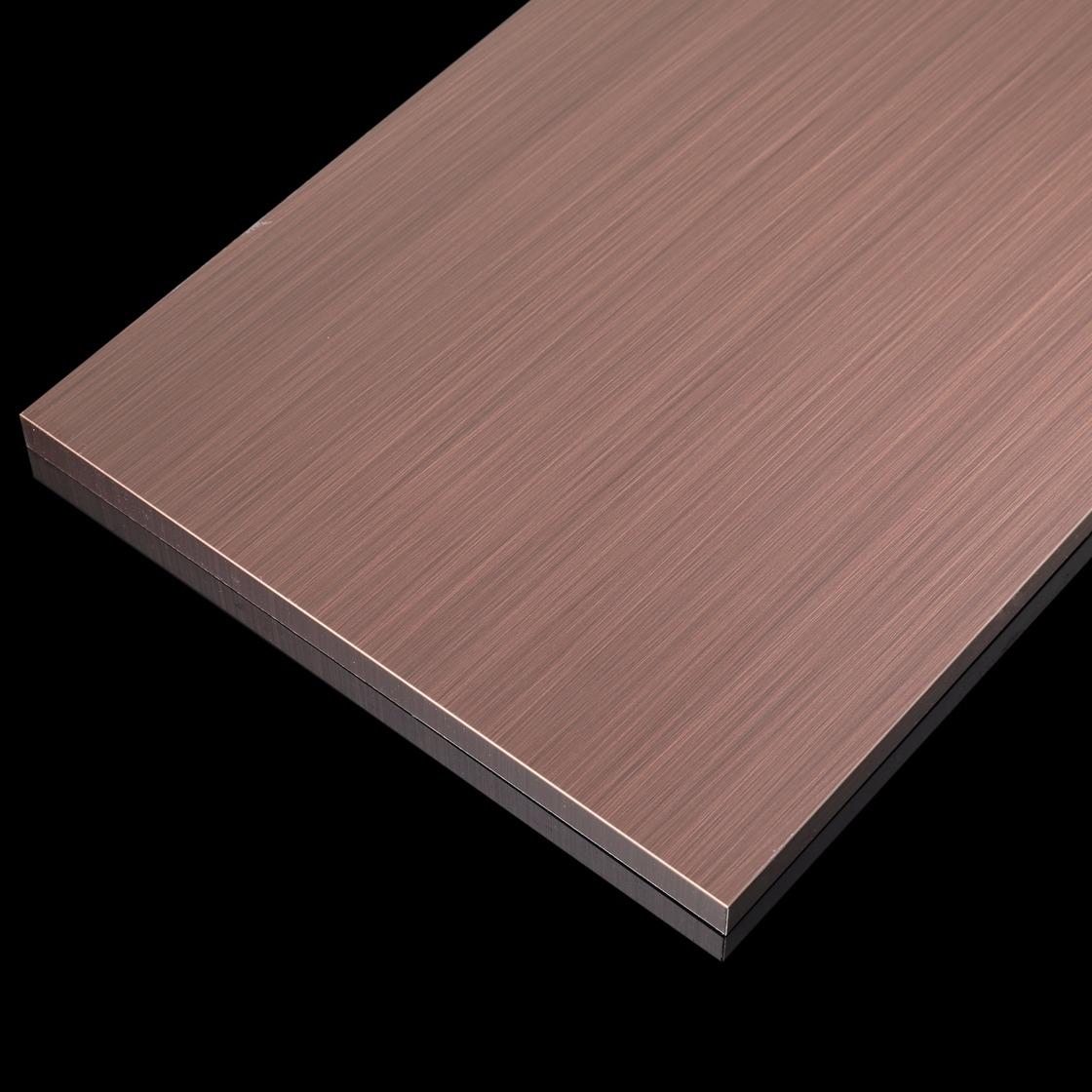

316 Stainless Steel Sheet Factory

Step 4: Adjust The Sheet And Make The Final Bend

After making the initial bend, adjust the sheet to the desired bend angle using the metal brake. Make sure the sheet is held securely in place with the clamps. Apply pressure to the metal brake to achieve the desired bend angle slowly.

Step 5: Check The Bend Angle

Once you have made the final bend, check the bend angle using a protractor or a digital angle finder. Ascertain that the bend angle is exact and correct. If the bend angle is not exact, you can modify it further with the metal brake.

Step 6: Trim The Excess Material

After achieving the desired bend angle, trim the excess material using cutting tools such as a circular saw or jigsaw. Make sure you cut along the marked line to achieve a clean and precise cut.

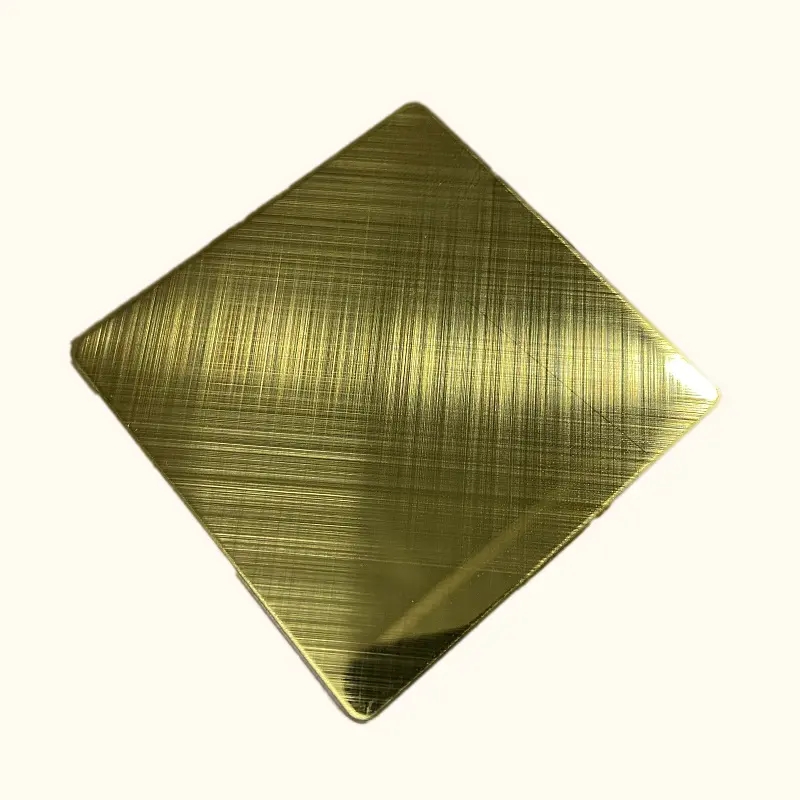

304 Stainless Steel Sheet Factory

Step 7: Unclamp and Inspect the Final Bend

With the excess material neatly trimmed, carefully remove the clamps to unveil the bent stainless steel sheet. Conduct a thorough inspection of the bend angle and the overall form to ensure that the sheet meets your specifications. This final assessment is crucial to confirm the success of your bending operation. If the sheet exhibits the precise angle and a clean bend, your efforts have culminated in a well-executed bend of the stainless steel sheet.

Conclusion

Mastering the art of bending stainless steel sheet metal is an invaluable skill that marries precision with strength. By following the outlined steps and employing the correct techniques and tools, you can achieve consistent and accurate bends, even with the more challenging grades like 304 stainless steel. Remember, practice and patience are key to perfecting this process. If you're in the market for top-tier stainless steel sheets or coils, consider XINGUANGYUAN, a premier supplier in China known for its quality products and service. For any inquiries or further assistance with your stainless steel needs, feel free to reach out to us.

FAQs

Q1: What is the minimum radius I can bend a stainless steel sheet without it cracking?

A1: The minimum bend radius for stainless steel sheets varies depending on the thickness and grade of the material. For instance, for 304 stainless steel, a good rule of thumb is to maintain a minimum bend radius that's equal to the sheet thickness. However, for more precise applications, it's recommended to use a bend radius that's at least 2 times the thickness of the sheet to reduce the risk of cracking.

Q2: Can I bend stainless steel sheets without a metal brake?

A2: While a metal brake is the preferred tool for bending stainless steel sheets due to its ability to apply even pressure and create clean bends, it is possible to bend stainless steel without one. Alternative methods include using a vise and hammer, though these are typically less precise and more labor-intensive. For thin sheets, a makeshift brake can be created with a few clamps and a sturdy work surface, but the results may vary.

Q3: How do I prevent stainless steel from springing back after bending?

A3: Spring-back is a common issue when bending stainless steel due to its high strength and elasticity. To minimize spring-back, over-bend the sheet slightly beyond the desired angle, as it will naturally spring back a bit after the bending force is removed. The amount of over-bending required will depend on the grade of stainless steel and the thickness of the sheet. It's often a matter of trial and error, so consider practicing on scrap pieces to determine the right amount of over-bend for your specific application.