Cutting stainless steel sheets requires precision and the right techniques to overcome the challenges posed by its strength and resistance to corrosion. Whether you're working on a DIY project or in a professional manufacturing setting, mastering the art of cutting stainless steel is essential for achieving clean, precise cuts. This guide will walk you through the best tools, techniques, and safety practices for cutting stainless steel sheet metal effectively. From selecting the appropriate cutting tool to ensuring a smooth finish, we'll cover everything you need to know to achieve professional-grade results.

5 Steps to Cut Stainless Steel Sheet

To cut stainless steel sheets effectively, follow these five essential steps:

Prepare and Measure: Gather necessary tools, including safety gear, the stainless steel sheet, cutting tool, cutting wheel, clamps, and a straight edge. Measure and mark the sheet accurately using a marker or scribe, ensuring straight lines with a straight edge. For curved cuts, use a compass or curved edge.

Stainless Steel Sheet Wholesale

Secure the Sheet: Place the stainless steel sheet on a stable workbench and secure it with clamps to prevent movement during cutting.

Wear Safety Gear: Put on safety glasses, gloves, and a face mask to protect yourself from metal shards and dust.

Stainless Steel Sheet Manufacturers In China

Cut the Sheet: Choose the right cutting tool based on your project needs. For DIY projects, an angle grinder or metal cutting saw with a stainless steel cutting wheel is suitable. For more complex cuts, consider a plasma cutter. Follow the marked line with a steady hand, maintaining consistent pressure and avoiding excessive force.

Inspect and Finish: After completing the cut, inspect it for cleanliness and straightness. Use a file or sandpaper to smooth out any rough edges.

Stainless Steel Sheet Distributors

Choosing the Right Cutting Tool for Stainless Steel Sheets

Selecting the appropriate cutting tool is crucial for achieving clean and precise cuts in stainless steel sheets. Here are some of the most effective tools for different applications:

Jigsaw: Ideal for curved cuts in thinner sheets. Use a carbide blade designed for stainless steel.

Circular Saw: Suitable for straight cuts in medium to thick sheets. Ensure you use a metal cutting blade.

Angle Grinder: Versatile for complex shapes and effective for both thin and thick sheets. Use an abrasive cutting disc.

Plasma Cutter: Best for thick sheets and precise cuts. Requires proper setup and safety precautions.

Laser Cutter: Offers the highest precision for intricate designs. Ideal for professional applications.

Each tool has its advantages and is suited for specific types of cuts and sheet thicknesses.

Tips For Cutting Stainless Steel Sheet

To achieve the best results when cutting stainless steel sheets, consider these essential tips:

Select the Right Tool: For DIY projects, a metal cutting saw or angle grinder is often sufficient. For more complex cuts, consider advanced tools like plasma or laser cutters.

Use the Correct Cutting Wheel: An abrasive cutting wheel made from materials like aluminum oxide or zirconia alumina is ideal for stainless steel.

Secure the Sheet: Clamp the sheet firmly to prevent movement during cutting.

Prioritize Safety: Always wear safety glasses, gloves, and a face mask to protect yourself from metal shards and dust.

Work Patiently: Take your time to ensure clean, precise cuts. Rushing can lead to mistakes and damage to your tools.

Conclusion

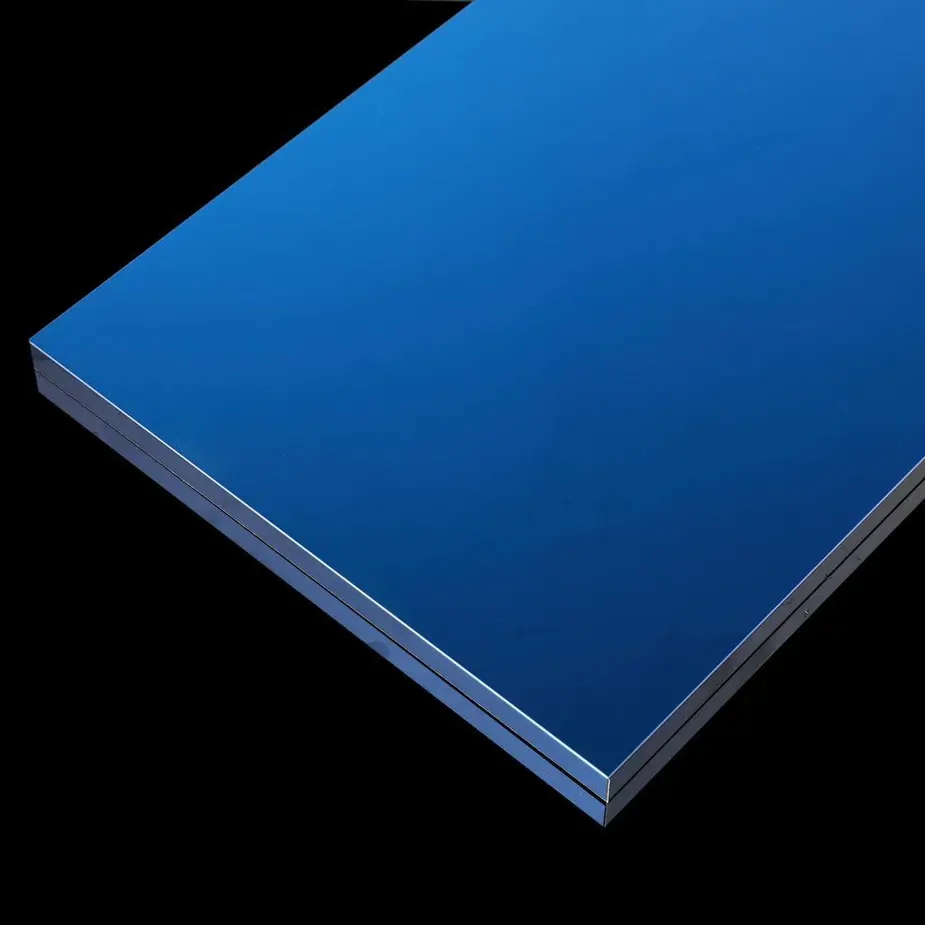

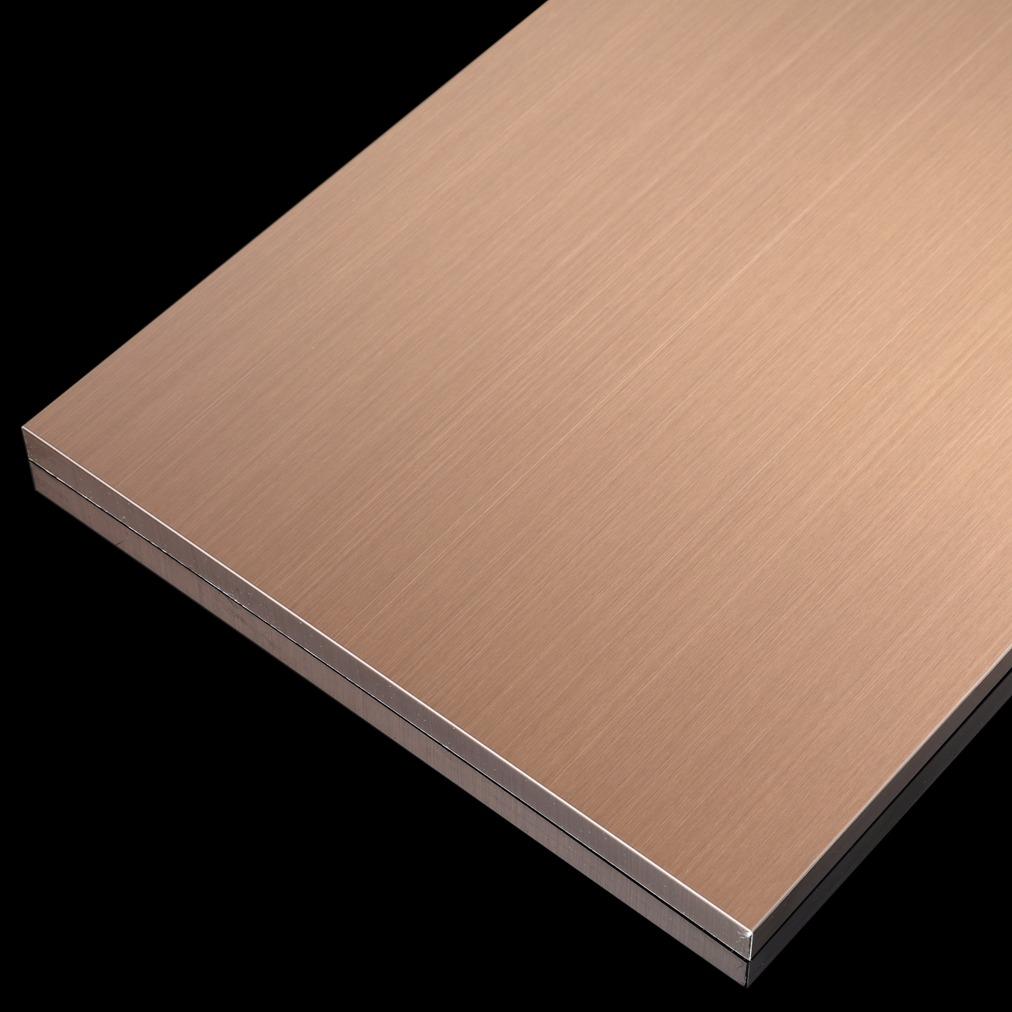

Securing a professional-grade cut on stainless steel sheets is all about precision, patience, and the right approach. By carefully selecting your tools and equipment and applying the correct cutting methods, you can consistently produce clean, precise cuts. For those looking to source high-quality stainless steel sheets, XINGUANGYUAN stands out as a leading provider. Based in China, we cater to a diverse range of project needs with our extensive selection of stainless steel sheet finishes and textures. We offer an extensive selection of stainless steel sheet styles, including the sleek no.8 mirror finish, sophisticated hairline textures, and intricate etching patterns. Discover the perfect stainless steel sheets for your needs with XINGUANGYUAN. Contact us today for more information and to explore our product range!

FAQs

- What is the best way to cut a stainless steel sheet at home?

Answer: The best method for cutting stainless steel at home depends on the tools you have available and the thickness of the sheet. For thin sheets, a metal cutting shear or tin snips might suffice. For thicker sheets, an angle grinder with a disc suitable for stainless steel or a circular saw with a metal cutting blade is often preferred. Always ensure you have adequate safety gear, including gloves and eye protection, and secure the sheet properly before cutting.

- Can I cut a stainless steel sheet with a hacksaw?

Answer: Yes, a hacksaw can be used to cut thinner stainless steel sheets, but it requires significant effort and the correct type of blade, typically a bi-metal blade with 18 to 24 teeth per inch. It's important to clamp the sheet down securely and use cutting oil to reduce friction and heat buildup, which can make cutting with a hacksaw more manageable.

- How do I prevent burring when cutting stainless steel sheet metal?

Answer: To minimize burring when cutting stainless steel sheet metal, use a sharp cutting tool and apply steady, moderate pressure to make a smooth cut. Cutting at a slower speed can also help reduce burring. After cutting, deburr the edges with a file, deburring tool, or sandpaper to smooth out any roughness. Using cutting lubricants can also help to produce a cleaner cut and reduce the chance of burning.