Stainless steel has long been revered for its durability, resistance to corrosion, and aesthetic appeal. Among the various finishes available, the hairline finish stands out as a unique combination of elegance and practicality. This article delves into the characteristics, applications, and advantages of stainless steel hairline finish, revealing why it is a preferred choice for modern design.

What is Stainless Steel Hairline Finish?

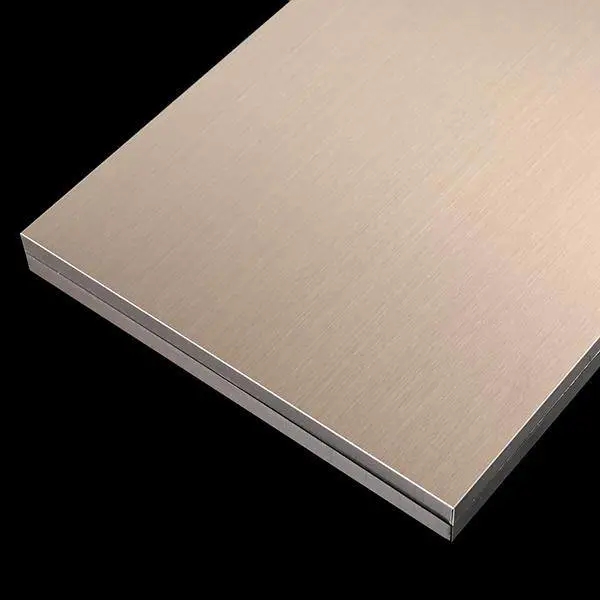

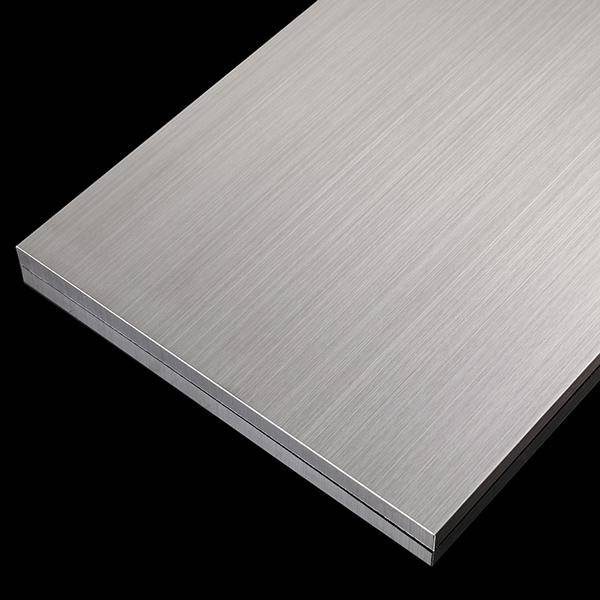

The hairline finish is a surface treatment that creates fine, uniform scratches on stainless steel, resembling the texture of human hair. This finish is achieved through mechanical processes such as grinding and polishing, resulting in a subtle and refined appearance that enhances the visual quality of stainless steel products.

Characteristics of Hairline Finish

-

Textural Appearance: The hairline finish features delicate lines that run parallel along the surface, providing a sophisticated look without being overly reflective. This understated elegance makes it suitable for various design aesthetics.

-

Durability: Beyond aesthetics, the hairline finish improves wear resistance. The textured surface can effectively hide minor scratches and abrasions, maintaining its attractive appearance over time.

-

Ease of Maintenance: Unlike polished surfaces that easily show fingerprints and smudges, hairline finishes are less prone to displaying such marks. This quality makes them easier to clean and maintain in both residential and commercial settings.

Advantages of Stainless Steel Hairline Finish

1. Aesthetic Versatility

The hairline finish complements a wide range of design styles—from modern minimalism to classic elegance. Its ability to scatter light creates dynamic visual effects, enhancing the overall ambiance of any space.

2. Functional Benefits

The unique texture not only contributes to aesthetics but also provides practical benefits:

-

Conceals Wear: The fine lines help mask wear and tear from everyday use, making it ideal for high-traffic areas.

-

Corrosion Resistance: Although not as resistant as some other finishes in coastal environments due to salt exposure, hairline finishes still offer good protection against rust when properly maintained.

Stainless Steel Hairline Finish

3. Application Diversity

Hairline-finished stainless steel is widely used across various sectors:

-

Architectural Elements: Commonly utilized in building exteriors and interiors, including walls, columns, and decorative panels.

-

Home Appliances: Frequently found in kitchen appliances like refrigerators and ovens where a sleek appearance is desired.

-

Furniture Design: Used in tables, chairs, and decorative accessories to add a touch of luxury without overwhelming other design elements.

Manufacturing Process of Hairline Finish

Achieving a hairline finish involves several steps:

Step 1: Surface Preparation

Initial grinding removes rough edges from the stainless steel surface. This step sets the foundation for achieving a uniform texture.

.jpg)

Stainless Steel Coil Wholesale

Step 2: Mechanical Abrasion

Using specialized tools, fine lines are created on the surface through brushing or polishing techniques. The direction of these lines can be adjusted to achieve desired aesthetic effects.

Step 3: Final Polishing

A final polish may be applied to enhance the texture further while ensuring that the surface remains smooth to the touch.

Conclusion

Stainless steel with a hairline finish represents an ideal blend of style and durability. Its unique texture not only enhances aesthetic appeal but also offers practical benefits that make it suitable for various applications. Whether used in architecture, interior design, or consumer products, the hairline finish continues to gain popularity among designers and manufacturers alike.

Incorporating hairline-finished stainless steel into your designs can elevate both functionality and elegance, making it a timeless choice for modern living spaces. As trends evolve towards minimalism and sophistication, the allure of this elegant finish will undoubtedly remain strong in the years to come.