Stainless steel is an extremely adaptable and frequently utilized material in a wide range of industries, including construction, manufacturing, and kitchen appliances. Its corrosion resistance, durability, and aesthetic appeal make it a popular option. However, the final surface finish of stainless steel can significantly impact its performance and appearance. In this article, we will explore the various surface finish options available for stainless steel and the factors to consider when choosing the right one.

Factors To Consider

Here are some factors to consider:

Application

The first and most important consideration in selecting a stainless steel surface treatment is its intended application. Different industries require specific finishes to meet their unique requirements. A polished surface, for example, could be ideal for a decorative railing in a luxury hotel, while a brushed or matte finish might be better for a kitchen countertop to decrease brightness and hide scratches.

Corrosion Resistance

One of the key benefits of stainless steel is its corrosion resistance. However, not all surface finishes offer the same level of protection. A polished finish, for instance, may be more susceptible to staining and corrosion compared to a passivated or electropolished finish. When choosing a surface finish, it is critical to understand the environment and potential exposure to corrosive elements.

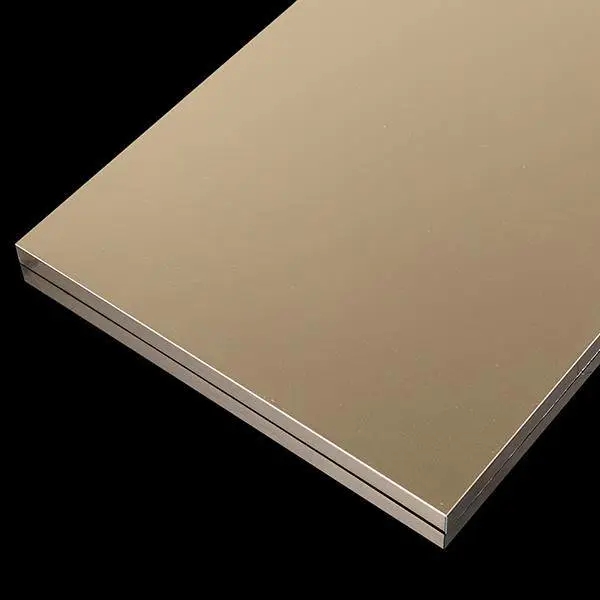

.jpg)

Anti-Fingerpring Stainless Coil

Aesthetic Preferences

The visual appeal of stainless steel is a significant consideration in many applications. Surface finishes can dramatically affect the appearance of stainless steel. The decision should fit with your design choices and the overall look of the project, ranging from mirror-like polished finishes to satin-like brushed finishes.

Surface Finish Options

Here are some common surface finish options:

Polished Finish

Polished finishes provide a high-gloss, reflecting surface, such as #4 (architectural) and #8 (mirror). These finishes are popular in decorative and architectural applications, including handrails, elevator doors, and ornamental structures. However, polished finishes may require more maintenance to retain their shine and are more prone to visible scratches.

Brushed Finish

The look of brushed finishes, often known as satin or matte surfaces, is more muted. They are created by brushing the stainless steel surface, resulting in a regular and appealing grain pattern. Brushed finishes are ideal for surfaces that require both aesthetics and durability, such as kitchen appliances, sinks, and some architectural elements.

Decorative Gold Hairline Stainless Steel Sheets

Passivated Finish

Passivation is a chemical process that removes free iron from the surface of stainless steel, enhancing its corrosion resistance. This finish is frequently utilized in medical and pharmaceutical applications where the steel must be biocompatible and chemically resistant.

Electropolished Finish

Electropolishing is an electrochemical technique that removes a thin layer of metal from the surface of stainless steel, producing a clean, brilliant finish with improved corrosion resistance. It is commonly used in the pharmaceutical, food processing, and semiconductor industries where a highly sanitary and smooth surface is crucial.

Decorative Embossed Stainless Steel Sheets

Bead Blasted Finish

Bead blasting is a method that uses tiny glass beads to launch at stainless steel to create a textured, non-reflective surface. This finish is suitable for applications where reduced glare, fingerprint resistance, and a unique texture are desired, such as elevator interiors and decorative architectural elements.

Mirror Finish (No. 8)

The No. 8 mirror finish embodies elegance and great reflectivity. It is accomplished via a thorough polishing procedure that results in a pristine, mirror-like surface. This finish is frequently used in architectural and interior design applications, as well as luxury consumer items and high-end kitchen equipment. It not only offers a brilliant shine but also a smooth, easy-to-clean surface. However, it can be more susceptible to visible scratches and may require regular maintenance to retain its luster.

Conclusion

Choosing the proper stainless steel surface treatment is a key choice that is dependent on your unique application, needs, and design preferences. Each finish offers a distinct combination of aesthetics, durability, and corrosion resistance. If you are looking for different stainless steel sheet or stainless steel coil, XINGUANGYUAN is ideal for you. Please feel free to contact us at [email protected] for more product details!