When it comes to purchasing stainless steel sheets, there are several factors to consider to ensure you make the right choice. Stainless steel sheets are versatile materials used in various industries, including construction, manufacturing, and interior design. They are a popular option for many applications due to its durability, corrosion resistance, and aesthetic appeal. Continue reading the post and discuss the key considerations to buy stainless steel sheets.

Material Grade

Stainless steel sheets are available in different material grades, each with its own unique properties and characteristics. When considering the material grade, it's essential to understand the specific requirements of your application. Here are some key common grades:

Grade 304: This is the most common stainless steel grade, known for its excellent corrosion resistance and versatility. It may be used for a variety of purposes, including food processing, culinary equipment, and architectural components.

Grade 316: If you require enhanced corrosion resistance, particularly in marine environments or chemical exposure, consider grade 316 stainless steel sheets. Molybdenum is present, which gives better resistance to pitting and crevice corrosion.

Grade 430: If price is a factor, grade 430 stainless steel sheets are a more affordable choice. While it has poorer corrosion resistance than grades 304 and 316, it nevertheless performs well in less demanding settings.

Thickness

The thickness of stainless steel sheets plays a crucial role in determining their strength and durability. Thicker sheets generally offer better resistance to impacts and bending forces. However, thicker sheets are also heavier and more expensive. Conversely, thinner sheets are lighter and more cost-effective but may be less robust for certain applications. The thickness of stainless steel sheet is commonly measured in gauges or millimeters.

To determine the appropriate thickness, consider the structural requirements of your project, including load-bearing capacity, expected forces, and the intended use of the stainless steel sheet.

Surface Finish

The surface finish of stainless steel sheets not only affects their appearance but also their performance and suitability for different applications. Here are some popular surface finishes to consider:

Brushed Finish: This finish provides a non-reflective, satin-like surface. It is achieved by brushing the stainless steel sheet with an abrasive material, resulting in a textured, muted appearance. Brushed finishes are frequently employed in architectural applications including interior design components and ornamental finishes.

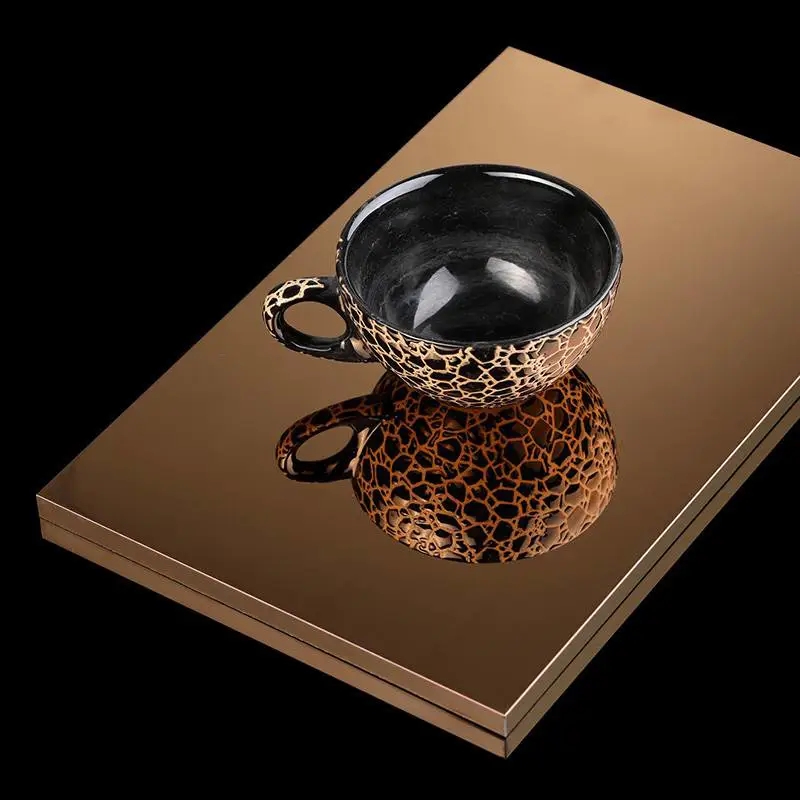

Mirror Finish: Mirror-finished stainless steel sheets offer a highly reflective surface, resembling a mirror. This finish is achieved through a series of polishing and buffing processes. Mirror finishes are frequently utilized in applications that demand an eye-catching and sophisticated look, such as ornamental accents and reflecting surfaces.

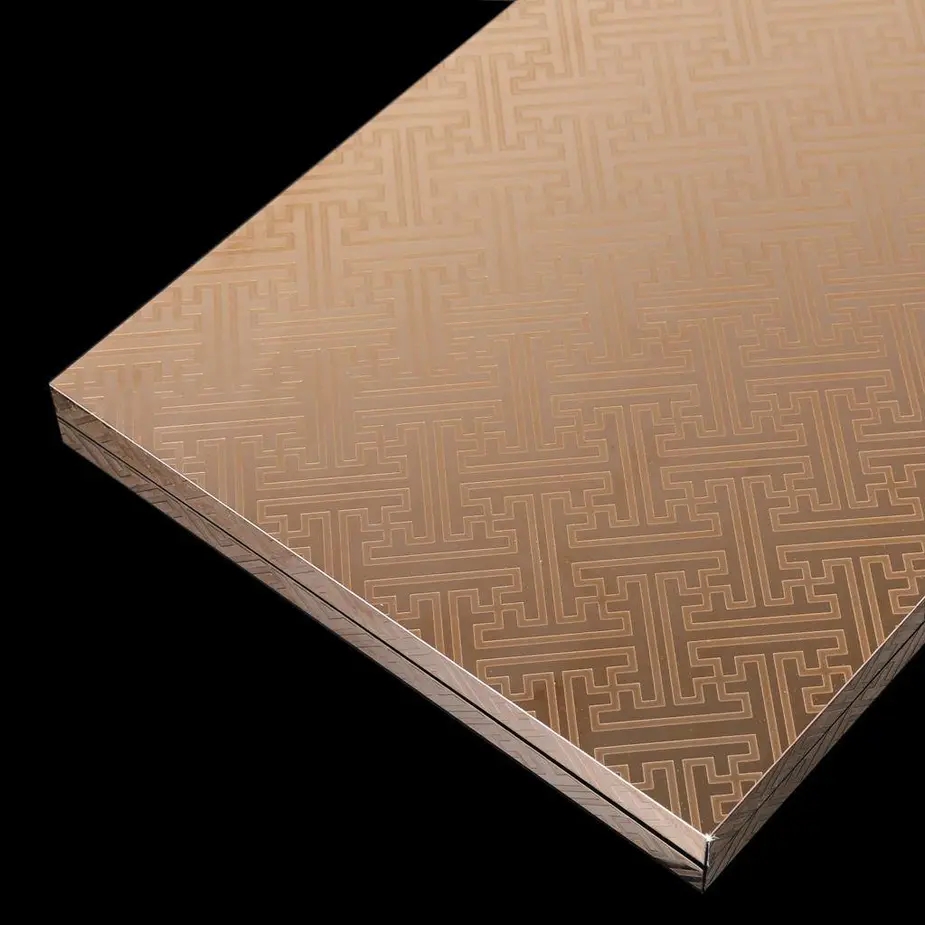

Textured Finish: Textured finishes involve embossing or patterned surfaces, adding both visual appeal and enhanced grip. These finishes can be achieved through techniques like roller embossing or chemical etching. Textured surfaces are often utilized in applications such as elevator panels, flooring, and external cladding when slip resistance or aesthetic improvement is sought.

Gold Mirror Stainless Steel Sheet Manufacturers

Corrosion Resistance

One of the primary advantages of stainless steel sheets is their inherent corrosion resistance. However, the level of corrosion resistance can vary depending on the material grade and environmental factors. Consider the following when evaluating corrosion resistance:

Material Grade: Corrosion resistance varies according to stainless steel grade. Grade 316, for example, has exceptional corrosion resistance, making it suited for applications that are exposed to seawater or severe chemicals. On the other hand, grade 430 has lower corrosion resistance compared to grades 304 and 316.

Environmental Factors: The operating environment plays a significant role in corrosion. Factors such as temperature, humidity, exposure to chemicals or saltwater, and atmospheric conditions can influence the corrosion resistance requirements of the stainless steel sheet. Consider these variables while deciding on the proper grade for the setting.

Maintenance: Cleaning and maintaining stainless steel sheets on a regular basis might assist to maintain their corrosion resistance. Avoid harsh cleaning agents and abrasive materials that may damage the protective layer on the surface. Proper care and maintenance will extend the lifespan and enhance the corrosion resistance of the stainless steel sheet.

Decorative Gold Mirror Stainless Steel Sheets

Conclusion

When purchasing stainless steel sheets, it's important to consider above factors. By the way, XINGUANGYUAN is specializing in produce stainless steel sheets with many experience. Looking for a new stainless steel sheets, we are ideal for you!