Stainless steel is a versatile and frequently used material that is well-known for its outstanding corrosion resistance. Stainless steel, unlike normal steel, has the unique ability to resist rust and corrosion even in hostile situations. This article will delve into stainless steel.

The Composition Of Stainless Steel

The composition of stainless steel can vary depending on the specific grade and application. However, the primary elements found in stainless steel are iron, chromium, and carbon. In addition to these, other elements such as nickel, molybdenum, and titanium can be added to enhance the material's properties.

Chromium is the essential element that gives stainless steel its anti-corrosive properties. When exposed to oxygen in the air, chromium reacts to form a thin, invisible, and self-repairing oxide layer on the surface of the steel. This protective layer is known as the "passive film." The passive coating functions as a barrier, keeping the underlying steel from coming into direct contact with corrosive chemicals and, as a result, preventing rust development.

The carbon content in stainless steel is generally kept low to maintain the material's corrosion resistance. Carbon can cause the development of chromium carbides, limiting the quantity of chromium available for passive film formation.

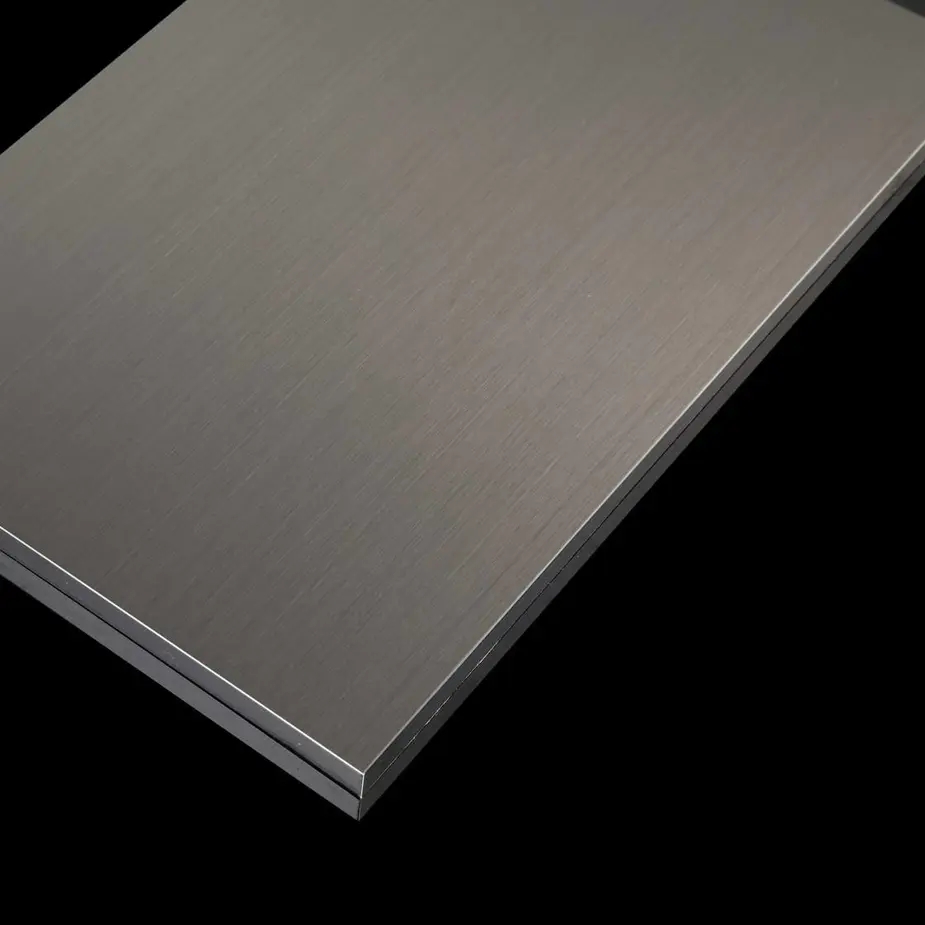

Black Hair Line Stainlee Steel Sheets

Why Doesn't Stainless Steel Rust?

The resistance of stainless steel against rust and corrosion is due to its particular composition and the creation of a protective layer on its surface. Let's explore the reasons in more detail:

Passive Film Formation

The key to stainless steel's rust resistance lies in the formation of a passive film on its surface. When stainless steel is exposed to oxygen in the air, particularly in the presence of moisture, the chromium content in the alloy reacts with the oxygen to form a thin, invisible, and tightly adhering oxide layer. This passive layer is largely made of chromium oxide (Cr2O3) and serves as a barrier between the underlying metal and corrosive chemicals.

The passive film is extremely stable and self-repairing. If the surface of the stainless steel is scratched or damaged, the passive film immediately reforms in the presence of oxygen. This phenomenon ensures continuous protection against corrosion, even after minor surface imperfections.

Chromium Content And Corrosion Resistance

The amount of chromium in stainless steel directly affects its corrosion resistance properties. The minimum chromium content required to be classified as stainless steel is 10.5% by mass. However, higher grades of stainless steel can have significantly higher chromium content, often exceeding 20% or more.

With increased chromium content, the passive film becomes more stable and robust, providing enhanced protection against corrosion. The high chromium content guarantees that the passive film remains intact even when subjected to harsh situations such as maritime or industrial applications.

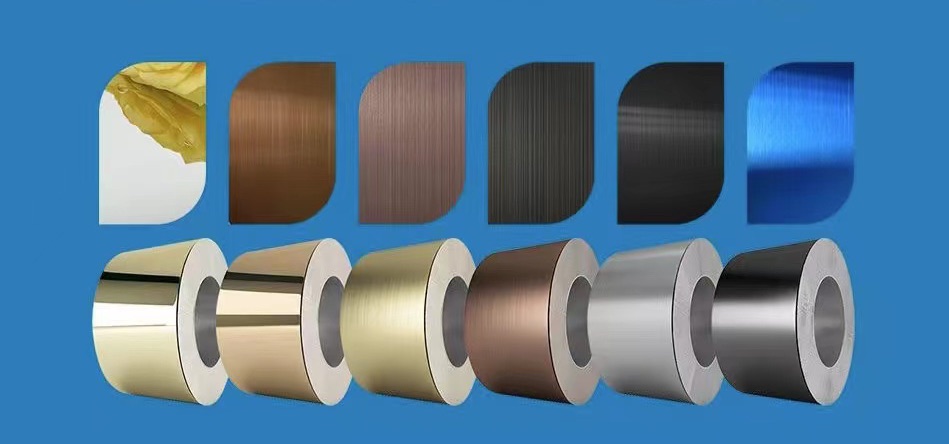

China 201 Stainless Steel Coil

Self-Repairing Mechanism

As mentioned earlier, the passive film has a remarkable ability to self-repair. If the stainless steel surface experiences any mechanical damage or abrasion that disrupts the passive film, the presence of oxygen is sufficient for the film to regenerate and restore its protective properties. This built-in self-repairing process helps the material's long-term resilience and resistance to corrosion.

Other Alloying Elements

While chromium is the primary element responsible for stainless steel's corrosion resistance, other alloying elements also play crucial roles in enhancing its properties. Nickel is often added to increase the stability of the passive film and improve resistance to specific corrosive agents.

Molybdenum is another important metal that improves the resistance of stainless steel against pitting and crevice corrosion, especially in chloride-rich conditions. Furthermore, nitrogen, titanium, and copper may be incorporated in various stainless steel grades to adapt their characteristics for specific uses.

Low Carbon Content

The carbon content in stainless steel is typically kept low, usually below 0.08%. High carbon content can lead to the formation of chromium carbides at grain boundaries, reducing the amount of available chromium for the formation of the passive film. This is known as sensitization, and it can damage stainless steel's corrosion resistance.

Conclusion

Stainless steel's exceptional resistance to rust and corrosion makes it an invaluable material in various industries and everyday applications. Therefore, whether it is stainless steel coil or sheet, it is widely used in various industries. At the same time, stainless steel products are also trendy because of their feature of not rusting. If you are looking for stainless steel coil or sheet even products, look no further than XINGUANGYUAN. Contact us today now!