In the ever-evolving world of industrial materials, stainless steel has emerged as a versatile and indispensable alloy, renowned for its exceptional corrosion resistance, durability, and aesthetic appeal. Among the various grades of stainless steel, 316 stainless steel coils have garnered significant attention from manufacturers and end-users alike, owing to their superior properties and wide-ranging applications.

This comprehensive article delves into the realm of 316 stainless steel coil manufacturers, exploring the intricacies of their production processes, the unique characteristics of this remarkable alloy, and the diverse industries that benefit from its use. Whether you're an engineer, architect, or simply an enthusiast of cutting-edge materials, this article promises to provide an in-depth understanding of the world of 316 stainless steel coil manufacturing.

What is 316 Stainless Steel?

Before delving into the manufacturing process, it's essential to understand the composition and properties that make 316 stainless steel a standout material. 316 stainless steel, also known as marine grade stainless steel, is an austenitic chromium-nickel alloy that contains molybdenum, a crucial element that enhances its resistance to pitting and crevice corrosion.

This unique alloy composition sets 316 stainless steel apart from other grades, making it an ideal choice for applications where exposure to harsh environments, such as seawater, deicing salts, or corrosive chemicals, is a concern. Its exceptional corrosion resistance, coupled with its high strength, ductility, and low maintenance requirements, has made it a go-to material for industries ranging from marine and chemical processing to architectural and decorative applications.

The Manufacturing Process of 316 Stainless Steel Coils

The journey of 316 stainless steel coils begins with the careful selection and melting of raw materials, including chromium, nickel, molybdenum, and other alloying elements. This molten metal is then cast into semi-finished products, such as slabs or billets, which undergo a series of intricate processes to transform them into the final coil form.

Hot Rolling and Cold Rolling

The initial stage involves hot rolling, where the semi-finished products are heated to high temperatures and passed through a series of rollers, gradually reducing their thickness and imparting the desired shape and dimensions. This process not only improves the mechanical properties of the steel but also prepares it for the subsequent cold rolling stage.

Cold rolling is a critical step in the manufacturing process, as it further reduces the thickness of the stainless steel coils and imparts a specific surface finish, such as hairline, mirror, or bead-blasted. During this process, the coils are passed through a series of rollers at room temperature, gradually reducing their thickness to the desired specifications while simultaneously enhancing their surface finish and mechanical properties.

Annealing and Surface Treatments

After the cold rolling process, the 316 stainless steel coils may undergo additional processes, such as annealing or surface treatments, to further enhance their properties or achieve specific characteristics. Annealing involves heating the coils to a specific temperature and then allowing them to cool slowly, which helps to relieve internal stresses and improve their ductility and formability.

Surface treatments, on the other hand, can impart unique finishes or coatings to the stainless steel coils, tailoring them to specific applications or aesthetic requirements. These treatments can include etching, embossing, or Physical Vapor Deposition (PVD) coatings, which can provide a wide range of color options and unique aesthetic effects.

Surface Finishes and Treatments

One of the key advantages of 316 stainless steel coils is the variety of surface finishes and treatments available, each offering unique properties and aesthetic appeal. These finishes not only enhance the visual appeal of the material but also cater to specific functional requirements, making 316 stainless steel coils a versatile choice for a wide range of applications.

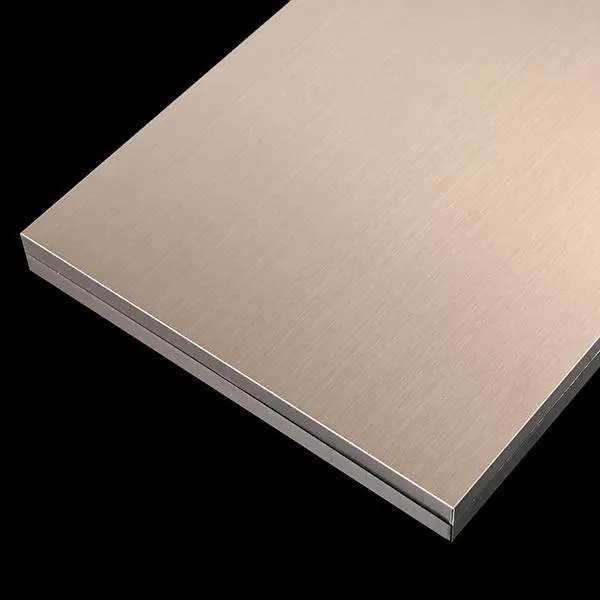

Hairline Finish

A hairline finish, also known as a brushed finish, is achieved by gently brushing the surface of the stainless steel coil in a unidirectional pattern, creating a subtle linear texture. This finish is popular for its attractive appearance and resistance to fingerprints and smudges, making it suitable for architectural and decorative applications, such as railings, cladding, and furniture.

Mirror Finish

A mirror finish, also known as a bright annealed finish, is achieved through a combination of cold rolling and annealing processes, resulting in a highly reflective and smooth surface. This finish is often used in decorative applications, such as cladding, furniture, and architectural elements, where a sleek and modern appearance is desired.

Bead-Blasted Finish

A bead-blasted finish is achieved by projecting small glass or ceramic beads at high velocity onto the surface of the stainless steel coil, creating a uniform matte or satin-like appearance. This finish is often used in industrial applications where a non-reflective surface is preferred, as well as in architectural and decorative settings for a unique and textured look.

PVD Coating

Physical Vapor Deposition (PVD) is a process that involves depositing a thin, decorative coating onto the surface of the stainless steel coil, creating a wide range of color options. PVD coatings can provide unique aesthetic effects, such as metallic or matte finishes, while maintaining the corrosion resistance and durability of the underlying stainless steel.

Embossed or Textured Finishes

Embossed or textured finishes are achieved by mechanically deforming the surface of the stainless steel coil, creating raised patterns or designs. These finishes are often used in architectural and decorative applications, adding visual interest and texture to the surface.

Applications of 316 Stainless Steel Coils

The exceptional properties of 316 stainless steel coils have made them a sought-after material in a wide range of industries, each leveraging their unique characteristics to meet specific functional and aesthetic requirements.

Marine and Offshore Industries

Due to their exceptional resistance to seawater and saltwater environments, 316 stainless steel coils are widely used in the marine and offshore industries. They are commonly employed in the construction of ships, offshore platforms, and other maritime structures, as well as in the manufacturing of components and equipment exposed to harsh marine conditions.

Chemical Processing and Pharmaceutical Industries

The chemical processing and pharmaceutical industries rely heavily on 316 stainless steel coils for their resistance to corrosive chemicals and their ability to maintain product purity. They are used in the fabrication of tanks, piping systems, and other equipment that handles aggressive chemicals or pharmaceutical products.

Food and Beverage Processing

316 stainless steel coils are widely used in the food and beverage industry due to their excellent hygiene properties and resistance to corrosion from acidic foods and beverages. They are commonly found in the construction of processing equipment, storage tanks, and food preparation surfaces, ensuring a safe and sanitary environment.

Architectural and Decorative Applications

The attractive appearance and durability of 316 stainless steel coils make them a popular choice for architectural and decorative applications. They are used in the construction of railings, cladding, furniture, and other decorative elements, adding a modern and sleek touch to both interior and exterior designs.

Medical and Healthcare Industries

The biocompatibility and corrosion resistance of 316 stainless steel coils make them suitable for use in the medical and healthcare industries. They are commonly used in the manufacturing of surgical instruments, implants, and other medical devices that require high levels of hygiene and durability.

Quality Control and Certification

Reputable 316 stainless steel coil manufacturers place a strong emphasis on quality control and adherence to industry standards and certifications. These measures ensure that the products meet the highest levels of quality, performance, and safety requirements, instilling confidence in end-users and customers.

Many manufacturers obtain certifications from recognized bodies, such as the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO), which validate the quality and consistency of their products. These certifications not only demonstrate the manufacturer's commitment to excellence but also provide assurance to customers that the 316 stainless steel coils they receive meet the specified standards and specifications.

Sustainability and Environmental Considerations

As the world becomes increasingly conscious of the environmental impact of industrial processes, 316 stainless steel coil manufacturers are actively pursuing sustainable practices and eco-friendly initiatives. Many manufacturers have implemented measures to reduce their carbon footprint, optimize resource utilization, and minimize waste generation throughout the production process.

Additionally, the inherent properties of 316 stainless steel coils, such as their durability and corrosion resistance, contribute to their sustainability. These characteristics extend the lifespan of products made from 316 stainless steel coils, reducing the need for frequent replacements and minimizing the consumption of raw materials and energy associated with new production.

Conclusion

The world of 316 stainless steel coil manufacturers is a testament to the ingenuity and innovation that drives the advancement of industrial materials. From the meticulous selection of raw materials to the intricate manufacturing processes and stringent quality control measures, every step is carefully orchestrated to produce a material that not only meets but exceeds the demands of diverse industries.

As we continue to explore the boundless potential of 316 stainless steel coils, manufacturers remain at the forefront, constantly refining their processes, developing new surface finishes, and pushing the boundaries of what is possible. Whether it's the sleek and modern aesthetic of a mirror finish or the rugged durability of a bead-blasted surface, 316 stainless steel coil manufacturers are poised to deliver solutions that cater to the ever-evolving needs of industries worldwide.

By embracing sustainable practices, adhering to stringent quality standards, and continuously innovating, these manufacturers are not only shaping the present but also paving the way for a future where 316 stainless steel coils continue to be a cornerstone of industrial excellence and architectural brilliance.

For those seeking a comprehensive understanding of the world of 316 stainless steel coil manufacturing, this article serves as a gateway, offering insights into the intricate processes, diverse applications, and the unwavering pursuit of quality that defines this remarkable industry.