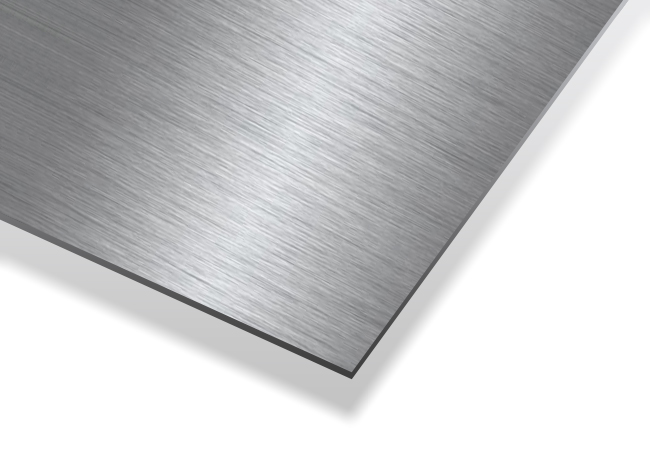

Sleek, modern, and built to last - brushed finish stainless steel sheets are transforming the world of design and architecture. But who are the top manufacturers delivering these sought-after materials without breaking the bank? This guide cuts through the noise to reveal the leading players in affordable, high-quality brushed stainless steel, exploring everything from cutting-edge production techniques to real-world applications that are reshaping our built environment.

What is Brushed Stainless Steel?

Brushed stainless steel, also known as satin stainless steel, is a finish applied to stainless steel that creates a distinctive, brushed appearance. This finish is achieved by using a wire brush or abrasive pad to create a pattern of fine lines on the surface of the stainless steel. The brushing process removes any surface imperfections or blemishes and creates a uniform grain on the surface, enhancing its durability and resistance to wear and tear.

Advantages of Brushed Stainless Steel Sheets

Brushed stainless steel sheets offer a multitude of benefits that make them a popular choice across various industries and applications. Let's explore the key advantages that set this versatile material apart:

Aesthetic Appeal and Design Versatility

Brushed stainless steel sheets boast a contemporary, sophisticated look that elevates any design. The matte finish, created by fine linear textures, provides a subtle sheen that's less reflective than polished stainless steel. This unique aesthetic makes it ideal for:

- Modern, minimalist architectural designs

- Sleek appliance exteriors

- Stylish furniture and decor accents

- High-end retail displays

The versatility of brushed stainless steel allows designers to create visually striking contrasts or seamless integrations within diverse environments, from residential kitchens to commercial spaces.

Exceptional Durability and Longevity

One of the standout features of brushed stainless steel sheets is their remarkable durability:

- Corrosion resistance: The chromium content forms a protective oxide layer, safeguarding against rust and corrosion.

- Heat resistance: Capable of withstanding high temperatures without warping or degrading.

- Impact resistance: The material's inherent strength helps it maintain its integrity under stress.

The brushing process actually enhances these properties by creating a slightly textured surface that's more resistant to scratches and wear. This makes brushed stainless steel sheets an excellent choice for:

- High-traffic areas in commercial buildings

- Industrial equipment and machinery

- Outdoor architectural elements exposed to the elements

Superior Hygiene and Easy Maintenance

The non-porous nature of brushed stainless steel sheets contributes to their exceptional hygienic properties:

- Bacteria resistance: The smooth surface inhibits bacterial growth and accumulation.

- Easy cleaning: Simple to sanitize with standard cleaning products, without risk of damage.

- Stain resistance: Less likely to show fingerprints or water spots compared to polished finishes.

These qualities make brushed stainless steel a top choice for:

- Healthcare facilities and laboratories

- Food preparation areas in restaurants and homes

- Public restrooms and high-touch surfaces

Sustainability and Environmental Benefits

In an era of increasing environmental consciousness, brushed stainless steel sheets stand out for their sustainability:

- 100% recyclable: Can be recycled indefinitely without loss of quality.

- Long lifespan: Reduces the need for frequent replacements, minimizing waste.

- Energy-efficient production: Modern manufacturing processes have reduced the environmental impact.

By choosing brushed stainless steel, businesses and consumers contribute to a more circular economy and reduce their carbon footprint.

Cost-Effectiveness Over Time

While the initial investment in brushed stainless steel sheets may be higher than some alternatives, the long-term benefits often result in cost savings:

- Reduced maintenance costs: Less frequent need for repairs or replacements.

- Energy savings: Reflective properties can contribute to better temperature regulation in buildings.

- Increased property value: The premium look and durability can enhance resale value in both residential and commercial properties.

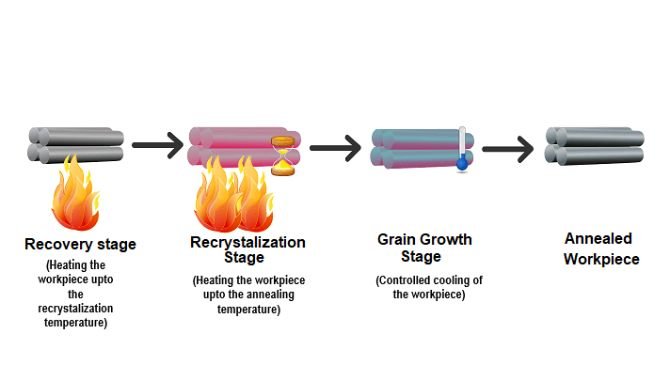

Manufacturing Process of Brushed Stainless Steel Sheets

The manufacturing process of brushed stainless steel sheets is a meticulous journey that transforms raw stainless steel into a sophisticated, aesthetically pleasing material with enhanced properties. This process involves several critical stages, each contributing to the final product's quality, appearance, and performance.

1. Raw Material Selection and Preparation

The process begins with carefully selecting high-quality stainless steel sheets, typically grades 304 or 316 for their excellent corrosion resistance and durability. These sheets undergo thorough inspection to ensure they meet the required specifications for thickness, composition, and surface quality.

2. Surface Preparation

Before the brushing process can begin, the stainless steel sheets must be meticulously prepared:

- Cleaning: The sheets are thoroughly cleaned using industrial-grade degreasers and solvents to remove any oils, dirt, or contaminants that could interfere with the brushing process.

- Pickling: A critical step where the sheets are immersed in a mixture of nitric and hydrofluoric acids. This process removes any surface impurities, mill scale, or oxidation layers, revealing a clean, bare metal surface.

- Passivation: Following pickling, the sheets undergo passivation treatment. This involves exposing the surface to a mild oxidizing agent, typically nitric acid, which forms a thin, transparent oxide layer. This layer significantly enhances the stainless steel's corrosion resistance.

3. Brushing Process

The hallmark of brushed stainless steel is its distinctive linear finish, achieved through a carefully controlled brushing technique:

- Brush Selection: Manufacturers choose specific abrasive brushes based on the desired finish. These brushes typically consist of nylon or wire bristles impregnated with abrasive materials like silicon carbide or aluminum oxide.

- Brushing Technique: The sheets are fed through industrial brushing machines where rotating brushes create fine, parallel lines on the surface. The angle, pressure, and speed of the brushes are precisely controlled to ensure consistency.

- Finish Variations: By adjusting the brushing parameters, manufacturers can create different finishes, from fine, subtle lines to more pronounced textures. Common finishes include:

- No. 4 Finish: A standard brushed finish with visible, uniform graining

- Hairline Finish: An extremely fine, almost imperceptible linear pattern

4. Quality Control and Finishing

After the brushing process, the sheets undergo rigorous quality control:

- Visual Inspection: Trained inspectors examine the sheets under specialized lighting to ensure uniformity and detect any imperfections.

- Surface Measurement: Advanced instruments measure the surface roughness to confirm it meets the specified parameters.

- Protective Coating: Many manufacturers apply a thin, clear protective film to the brushed surface. This film safeguards the finish during transportation and installation, and is easily removed by the end-user.

5. Cutting and Shaping

While some applications require full sheets, many projects need specific sizes or shapes:

- Precision Cutting: State-of-the-art laser or water jet cutting systems are used to cut the brushed sheets to exact specifications without damaging the finish.

- Edge Finishing: Cut edges are carefully deburred and may receive additional finishing to match the brushed surface.

By following this comprehensive process, manufacturers produce brushed stainless steel sheets that combine aesthetic appeal with the inherent strength and corrosion resistance of stainless steel. These versatile materials find applications in architecture, interior design, appliance manufacturing, and numerous other industries where a sophisticated, durable finish is desired.

Applications of Brushed Stainless Steel Sheets

Brushed stainless steel sheets are used in a wide range of applications due to their aesthetic appeal and durability:

- Architectural Elements: Brushed stainless steel is commonly used in architectural elements such as wall claddings, elevator doors, and handrails due to its sleek and modern appearance.

- Interior Design: The material is popular in interior design for applications such as kitchen appliances, countertops, and furniture legs. Its ability to hide fingerprints and scratches makes it ideal for high-traffic areas.

- Industrial Applications: Brushed stainless steel is used in industrial applications such as machinery, equipment, and tools due to its durability and resistance to wear and tear.

- Medical and Laboratory Equipment: The non-porous and easy-to-clean nature of brushed stainless steel makes it a preferred choice for medical and laboratory equipment.

Market Trends in Brushed Stainless Steel Sheets

The latest design trends in stainless steel sheets focus on texture, color, and sustainability:

- Textured Finishes: Manufacturers are introducing textured finishes such as brushed, embossed, and hammered finishes to add depth and texture to the material.

- Colored Stainless Steel: Colored stainless steel sheets are becoming increasingly popular in interior design. These sheets are available in a range of colors, including gold, rose gold, black, and bronze, and can be used for various decorative purposes.

- Laser-Cut Designs: Laser-cutting technology allows for intricate designs to be cut into stainless steel sheets, creating unique patterns and designs for decorative elements such as screens, partitions, and balustrades.

- Mixed Materials: Stainless steel sheets are being combined with other materials such as glass, wood, and stone to create modern and unique design elements.

Sustainability of Brushed Stainless Steel Sheets

Stainless steel is a highly sustainable material due to its recyclability and durability:

- Recyclability: Stainless steel is 100% recyclable, making it an eco-friendly material choice. It can be recycled without losing its properties, reducing the need for raw materials and minimizing environmental impact.

- Durability: The long lifespan of stainless steel products reduces the need for frequent replacements, contributing to sustainability by lowering the overall consumption of resources.

- Eco-Friendly Manufacturing: Many manufacturers are adopting eco-friendly practices in the production of stainless steel sheets, such as using energy-efficient processes and reducing waste.

Quality Control and Standards

Ensuring the quality of brushed stainless steel sheets involves adhering to strict quality control measures and international standards:

- Material Quality: Manufacturers source high-quality stainless steel from certified vendors to ensure the durability and performance of the final product.

- Manufacturing Standards: Adherence to international standards such as ASTM, ISO, and EN ensures that the stainless steel sheets meet the required specifications for various applications.

- Inspection and Testing: Regular inspection and testing of the stainless steel sheets during the manufacturing process help identify and rectify any defects, ensuring a high-quality finish.

Conclusion

Brushed finish stainless steel sheets are a versatile and durable material choice for various applications, from architectural elements to industrial machinery. The combination of aesthetic appeal, durability, and sustainability makes them a popular choice in many industries. By understanding the manufacturing process, applications, market trends, and sustainability aspects, manufacturers can continue to innovate and meet the evolving needs of their clients.

For more information on brushed stainless steel sheets, you can explore our detailed guides on how to clean stainless steel coils, applications of mirror stainless steel sheets, and how to cut stainless steel sheets.